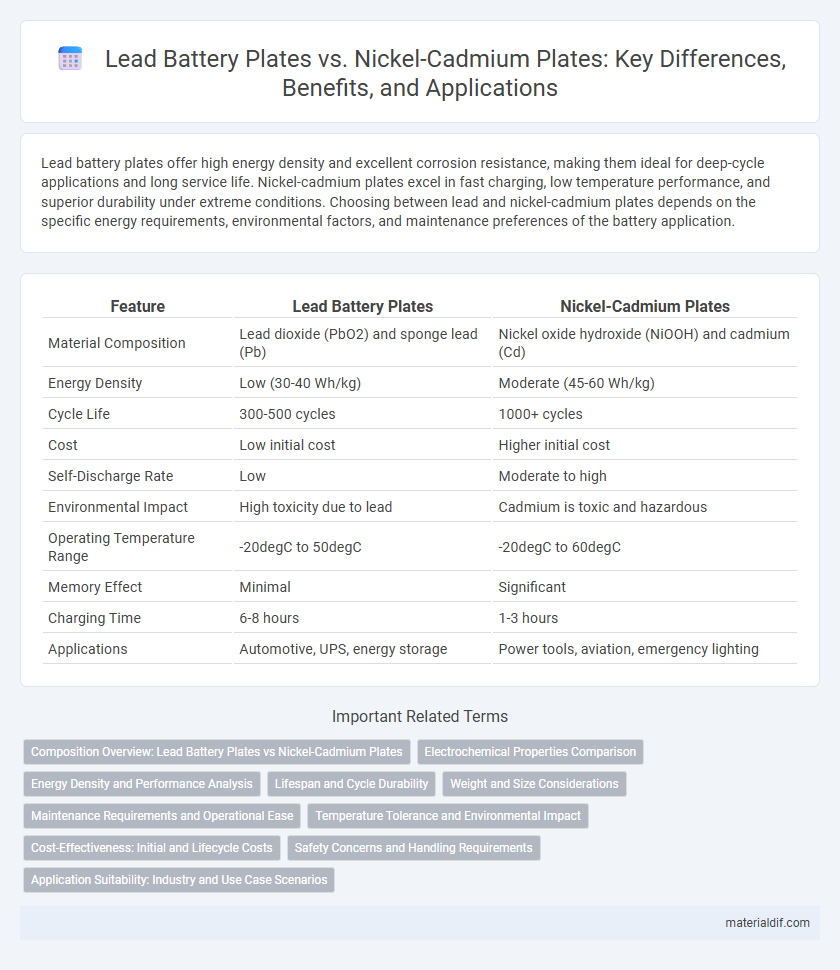

Lead battery plates offer high energy density and excellent corrosion resistance, making them ideal for deep-cycle applications and long service life. Nickel-cadmium plates excel in fast charging, low temperature performance, and superior durability under extreme conditions. Choosing between lead and nickel-cadmium plates depends on the specific energy requirements, environmental factors, and maintenance preferences of the battery application.

Table of Comparison

| Feature | Lead Battery Plates | Nickel-Cadmium Plates |

|---|---|---|

| Material Composition | Lead dioxide (PbO2) and sponge lead (Pb) | Nickel oxide hydroxide (NiOOH) and cadmium (Cd) |

| Energy Density | Low (30-40 Wh/kg) | Moderate (45-60 Wh/kg) |

| Cycle Life | 300-500 cycles | 1000+ cycles |

| Cost | Low initial cost | Higher initial cost |

| Self-Discharge Rate | Low | Moderate to high |

| Environmental Impact | High toxicity due to lead | Cadmium is toxic and hazardous |

| Operating Temperature Range | -20degC to 50degC | -20degC to 60degC |

| Memory Effect | Minimal | Significant |

| Charging Time | 6-8 hours | 1-3 hours |

| Applications | Automotive, UPS, energy storage | Power tools, aviation, emergency lighting |

Composition Overview: Lead Battery Plates vs Nickel-Cadmium Plates

Lead battery plates consist primarily of lead dioxide (PbO2) on the positive plate and sponge lead (Pb) on the negative plate, both submerged in sulfuric acid electrolyte to facilitate electrochemical reactions. Nickel-cadmium plates are composed of nickel oxide hydroxide (NiOOH) on the positive electrode and cadmium (Cd) on the negative, using an alkaline potassium hydroxide electrolyte that allows for higher cycle stability. The chemical composition differences directly influence energy density, charge-discharge efficiency, and lifespan, with lead plates favoring high current applications and Ni-Cd plates providing robust performance under varying loads.

Electrochemical Properties Comparison

Lead battery plates exhibit high electrochemical stability and superior capacity retention due to their lead dioxide active material, enabling efficient charge-discharge cycles with minimal sulfation. Nickel-cadmium plates offer excellent cyclic durability and fast recharge capability, attributed to the reversible redox reactions of nickel oxide hydroxide and cadmium. While lead plates provide higher energy density and better performance in deep discharge conditions, nickel-cadmium plates excel in low-temperature operation and resilience against memory effects.

Energy Density and Performance Analysis

Lead battery plates exhibit lower energy density compared to nickel-cadmium plates, making Ni-Cd batteries more suitable for applications demanding higher energy storage within compact spaces. Performance analysis reveals that nickel-cadmium plates maintain better charge retention and deliver higher discharge rates, enhancing efficiency and cycle life. Lead plates, while heavier and less energy-dense, offer cost advantages and reliability in low-demand, steady power applications.

Lifespan and Cycle Durability

Lead battery plates exhibit superior cycle durability compared to nickel-cadmium plates, often delivering between 500 to 1,000 charge-discharge cycles versus nickel-cadmium's typical 300 to 500 cycles. The lifespan of lead plates generally ranges from 3 to 5 years under optimal conditions, benefiting from their robust corrosion resistance and thicker plate design. Nickel-cadmium plates, while offering better performance at low temperatures, tend to suffer from memory effect and reduced lifespan, usually lasting around 2 to 3 years in regular use.

Weight and Size Considerations

Lead battery plates are significantly heavier and bulkier compared to nickel-cadmium plates, impacting overall battery weight and space requirements in applications like automotive or industrial equipment. The higher density of lead necessitates larger dimensions for equivalent energy storage, whereas nickel-cadmium plates offer a more compact and lightweight alternative, ideal for portable devices and aerospace technology. Weight and size considerations directly influence device efficiency, handling, and installation costs, making the choice between lead and nickel-cadmium plates critical for optimizing performance and design.

Maintenance Requirements and Operational Ease

Lead battery plates require regular watering and periodic equalizing charges to prevent sulfation and maintain capacity, making maintenance more demanding compared to nickel-cadmium plates. Nickel-cadmium plates exhibit superior tolerance to deep discharges and require minimal maintenance due to their resistance to sulfation and electrolyte stratification. The operational ease of nickel-cadmium batteries includes longer service life and less frequent servicing, offering advantages in industrial and heavy-duty applications.

Temperature Tolerance and Environmental Impact

Lead battery plates exhibit superior temperature tolerance, functioning efficiently between -40degC and 50degC, whereas nickel-cadmium plates withstand a wider range from -20degC to 70degC but experience capacity degradation at extreme temperatures. Environmentally, lead battery plates pose significant recycling challenges due to toxic lead content, while nickel-cadmium plates contain hazardous cadmium, a heavy metal with strict disposal regulations to prevent soil and water contamination. The environmental impact of nickel-cadmium batteries is higher because of cadmium's persistent toxicity, despite their better thermal resilience compared to lead-based counterparts.

Cost-Effectiveness: Initial and Lifecycle Costs

Lead battery plates offer lower initial costs compared to nickel-cadmium plates, making them more budget-friendly for large-scale energy storage applications. Over the lifecycle, lead plates demonstrate cost-effectiveness through easier recycling and maintenance, leading to reduced overall expenses. Nickel-cadmium plates, while durable, incur higher upfront and replacement costs due to more complex manufacturing processes and environmental handling requirements.

Safety Concerns and Handling Requirements

Lead battery plates require careful handling due to the toxic nature of lead and exposure risks during manufacturing and disposal, demanding strict safety protocols and protective equipment. Nickel-cadmium plates pose environmental hazards because of cadmium's high toxicity and persistence, necessitating specialized recycling and disposal methods to prevent soil and water contamination. Both battery types must adhere to regulatory guidelines to minimize health risks and ensure safe operational practices in industrial and consumer applications.

Application Suitability: Industry and Use Case Scenarios

Lead battery plates excel in automotive and stationary energy storage due to high corrosion resistance and cost-effectiveness, making them ideal for cars, trucks, and backup power systems. Nickel-cadmium plates offer superior performance in extreme temperatures and high-discharge applications, preferred in aerospace, military, and portable power tools. Each plate type matches specific industry needs: lead plates dominate high-capacity, low-maintenance roles, while nickel-cadmium suits specialized, rugged environments requiring long cycle life and reliability.

Lead Battery Plates vs Nickel-Cadmium Plates Infographic

materialdif.com

materialdif.com