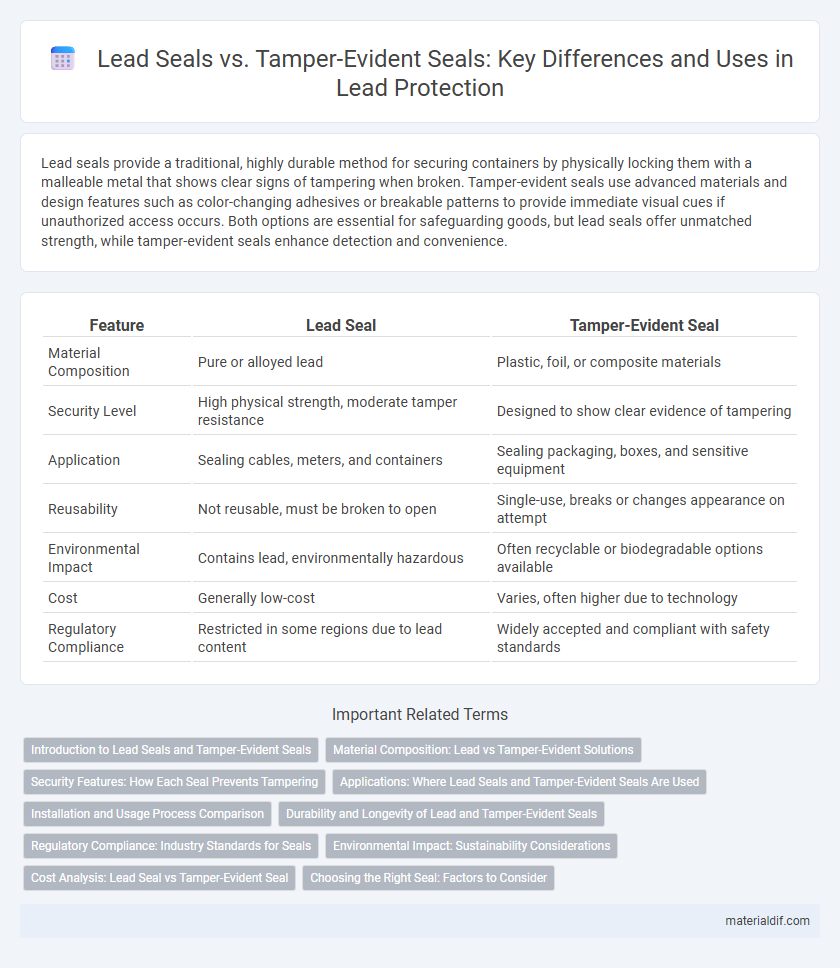

Lead seals provide a traditional, highly durable method for securing containers by physically locking them with a malleable metal that shows clear signs of tampering when broken. Tamper-evident seals use advanced materials and design features such as color-changing adhesives or breakable patterns to provide immediate visual cues if unauthorized access occurs. Both options are essential for safeguarding goods, but lead seals offer unmatched strength, while tamper-evident seals enhance detection and convenience.

Table of Comparison

| Feature | Lead Seal | Tamper-Evident Seal |

|---|---|---|

| Material Composition | Pure or alloyed lead | Plastic, foil, or composite materials |

| Security Level | High physical strength, moderate tamper resistance | Designed to show clear evidence of tampering |

| Application | Sealing cables, meters, and containers | Sealing packaging, boxes, and sensitive equipment |

| Reusability | Not reusable, must be broken to open | Single-use, breaks or changes appearance on attempt |

| Environmental Impact | Contains lead, environmentally hazardous | Often recyclable or biodegradable options available |

| Cost | Generally low-cost | Varies, often higher due to technology |

| Regulatory Compliance | Restricted in some regions due to lead content | Widely accepted and compliant with safety standards |

Introduction to Lead Seals and Tamper-Evident Seals

Lead seals provide a durable and corrosion-resistant method for securing containers, ensuring authenticity and preventing unauthorized access. Tamper-evident seals offer visible indicators of tampering by breaking or showing damage upon interference, enhancing security monitoring. Both seals serve as critical tools in safeguarding products, with lead seals emphasizing strength and tamper-evident seals prioritizing visual tamper detection.

Material Composition: Lead vs Tamper-Evident Solutions

Lead seals are composed primarily of pure or alloyed lead, providing robust physical durability and ease of molding for secure identification. Tamper-evident seals utilize advanced materials such as plastics, holographic foils, and adhesives designed to show visible signs of interference or damage upon unauthorized access. The material composition directly impacts security effectiveness, with lead offering mechanical strength and tamper-evident solutions delivering instant visual tampering cues.

Security Features: How Each Seal Prevents Tampering

Lead seals offer robust tampering protection through their malleable material that deforms irreversibly when broken, providing clear evidence of unauthorized access. Tamper-evident seals utilize specialized adhesives or locking mechanisms that display visible indicators such as color changes or broken patterns upon tampering attempts. The security effectiveness of lead seals lies in their physical material properties, while tamper-evident seals rely on engineered visual cues to deter and detect interference.

Applications: Where Lead Seals and Tamper-Evident Seals Are Used

Lead seals are widely used in industries like shipping, logistics, and utilities for securing cargo containers, meters, and valves, providing a robust physical barrier against unauthorized access. Tamper-evident seals find applications in pharmaceuticals, food packaging, and electronics to ensure product integrity by indicating any interference or contamination prior to consumption. Both types of seals serve critical roles in compliance and security, with lead seals favoring heavy-duty protection and tamper-evident seals excelling in visibility of breach.

Installation and Usage Process Comparison

Lead seals require manual threading and crimping onto the item using specialized pliers, ensuring a secure and tamper-resistant closure primarily used for high-security applications. Tamper-evident seals, often made from plastic or vinyl, feature adhesive backing or locking mechanisms that allow quick application and clear visual indication of interference, ideal for frequent inspections and temporary sealing. Installation of lead seals is more time-consuming and permanent, while tamper-evident seals offer faster deployment and easier removal without specialized tools.

Durability and Longevity of Lead and Tamper-Evident Seals

Lead seals exhibit exceptional durability and longevity due to their robust metal composition, resisting corrosion and environmental wear over extended periods. Tamper-evident seals, often made from plastic or composite materials, provide clear indications of interference but generally have shorter lifespans and can degrade faster under harsh conditions. The metal integrity of lead seals ensures they maintain secure fastening and identification integrity longer than tamper-evident alternatives in demanding environments.

Regulatory Compliance: Industry Standards for Seals

Lead seals comply with stringent industry standards such as ISO 17712, ensuring secure containment and tamper resistance in shipping and logistics. Tamper-evident seals meet regulatory requirements by providing clear visual indicators of unauthorized access, conforming to FDA and pharmaceutical industry guidelines. Both seal types play critical roles in maintaining supply chain integrity and adhering to government-mandated security protocols.

Environmental Impact: Sustainability Considerations

Lead seals pose significant environmental risks due to lead's toxicity and difficulty in recycling, contributing to soil and water contamination. Tamper-evident seals, often made from recyclable plastics or biodegradable materials, offer more sustainable alternatives with lower ecological footprints. Choosing tamper-evident seals supports environmental protection efforts by minimizing hazardous waste and promoting circular economy principles.

Cost Analysis: Lead Seal vs Tamper-Evident Seal

Lead seals typically incur higher initial costs due to material and labor-intensive application processes, whereas tamper-evident seals offer more cost-effective mass production and easier installation, reducing overall expenses. Despite the higher upfront investment, lead seals provide superior durability and long-term security, which can minimize replacement costs over time. Tamper-evident seals excel in cost efficiency for high-volume use, with scalable pricing that benefits industries prioritizing budget-conscious solutions.

Choosing the Right Seal: Factors to Consider

Selecting the right seal depends on security requirements, environmental conditions, and application type. Lead seals offer high durability and resistance to tampering, ideal for heavy-duty or industrial use, while tamper-evident seals provide clear visual indicators of unauthorized access, suitable for shipments and packaging. Consider factors such as ease of application, compliance standards, and cost-effectiveness to ensure optimal protection.

Lead Seal vs Tamper-Evident Seal Infographic

materialdif.com

materialdif.com