Leads made from natural fibers or woven materials offer superior durability and comfort compared to plastic leads, which can easily crack or break under stress. Natural fiber leads are environmentally friendly, providing a sustainable alternative that reduces plastic waste and pollution. Their breathable texture also reduces the risk of irritation for pets, ensuring safer and more comfortable walks.

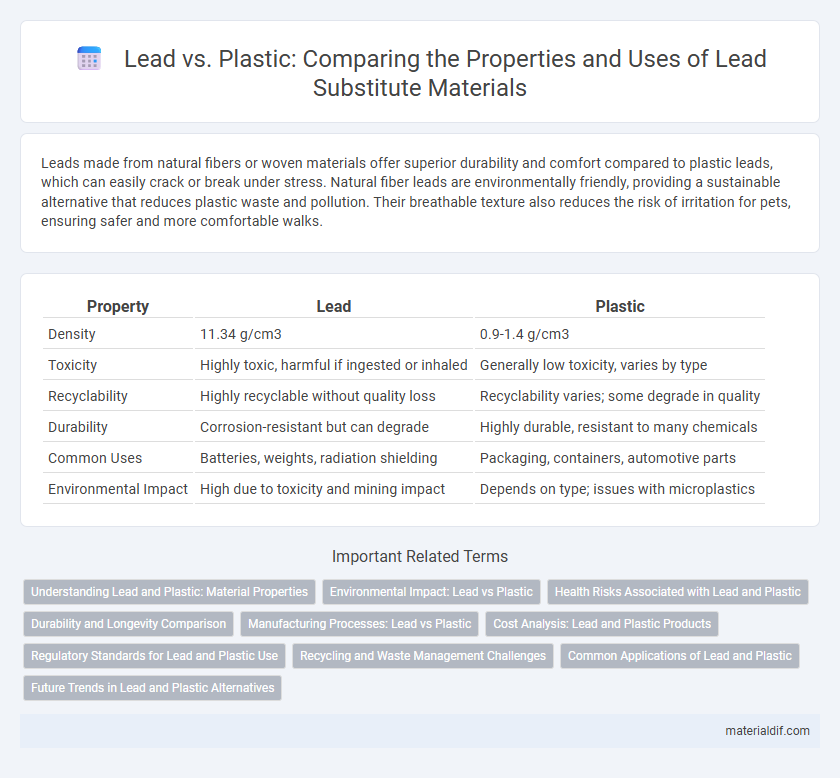

Table of Comparison

| Property | Lead | Plastic |

|---|---|---|

| Density | 11.34 g/cm3 | 0.9-1.4 g/cm3 |

| Toxicity | Highly toxic, harmful if ingested or inhaled | Generally low toxicity, varies by type |

| Recyclability | Highly recyclable without quality loss | Recyclability varies; some degrade in quality |

| Durability | Corrosion-resistant but can degrade | Highly durable, resistant to many chemicals |

| Common Uses | Batteries, weights, radiation shielding | Packaging, containers, automotive parts |

| Environmental Impact | High due to toxicity and mining impact | Depends on type; issues with microplastics |

Understanding Lead and Plastic: Material Properties

Lead exhibits high density, excellent malleability, and superior corrosion resistance, making it ideal for shielding and industrial applications. Plastic, characterized by its lightweight nature, flexibility, and diverse chemical compositions, offers versatile uses ranging from packaging to automotive parts. Understanding the distinct material properties of lead and plastic is crucial for selecting the appropriate material based on strength, durability, and environmental impact.

Environmental Impact: Lead vs Plastic

Lead poses significant environmental hazards due to its toxicity and persistence in soil and water, causing long-term contamination and bioaccumulation in wildlife. Plastic pollution contributes to widespread ecological damage through microplastics ingestion by marine and terrestrial organisms, disrupting ecosystems and entering food chains. While lead contamination is localized but severe, plastic pollution is pervasive and continuously accumulates, posing a global environmental challenge.

Health Risks Associated with Lead and Plastic

Lead exposure poses significant health risks, including neurological damage, cognitive impairment, and developmental delays, especially in children. Plastic materials can release harmful chemicals such as BPA and phthalates, which are linked to endocrine disruption and reproductive issues. Prolonged contact with lead or certain plastics increases the risk of chronic health problems, underscoring the importance of minimizing exposure to these substances.

Durability and Longevity Comparison

Lead exhibits superior durability compared to plastic due to its high density and resistance to physical wear, enabling it to withstand harsh environmental conditions without significant degradation. Unlike plastic, which can become brittle and degrade under UV exposure and temperature fluctuations, lead maintains its structural integrity over extended periods. This longevity makes lead a preferred material for applications requiring long-term stability and resilience.

Manufacturing Processes: Lead vs Plastic

Lead manufacturing involves casting and machining, leveraging its malleability and low melting point for precise shaping and often requiring minimal post-processing. Plastic manufacturing utilizes processes such as injection molding, extrusion, and thermoforming, offering high scalability and design flexibility through polymerization and melting techniques. The choice between lead and plastic manufacturing impacts production speed, cost-efficiency, and environmental considerations, with plastic enabling mass production and lead providing durability in specialized applications.

Cost Analysis: Lead and Plastic Products

Lead products generally incur higher upfront material costs compared to plastic due to lead's density and extraction expenses. Plastic offers lower production costs, driven by cheaper raw materials and streamlined manufacturing processes, making it more cost-effective for mass production. However, lead's durability and recyclability can reduce long-term costs in specialized applications.

Regulatory Standards for Lead and Plastic Use

Regulatory standards for lead usage are strictly enforced due to its toxicity, with agencies like the U.S. Environmental Protection Agency (EPA) setting limits on lead content in products and emissions to minimize human exposure. In contrast, plastic regulations primarily target chemical additives such as bisphenol A (BPA) and phthalates, with frameworks like the European Union's REACH restricting hazardous substances in plastic manufacturing. Compliance with these standards ensures safer alternatives are used, reflecting growing environmental and health concerns associated with lead and plastic materials.

Recycling and Waste Management Challenges

Lead poses significant challenges in recycling due to its toxicity and potential for environmental contamination, requiring specialized handling and disposal methods. Plastic recycling faces difficulties with contamination and the presence of diverse polymer types that complicate sorting and processing. Both materials demand advanced waste management strategies to minimize health risks and environmental impact, emphasizing the need for improved recycling technologies and regulatory oversight.

Common Applications of Lead and Plastic

Lead is commonly used in radiation shielding, batteries, and plumbing due to its high density and corrosion resistance, while plastic finds extensive applications in packaging, automotive parts, and consumer electronics because of its versatility and lightweight properties. Lead's use in cable sheathing and ammunition capitalizes on its malleability and toxicity, whereas plastic's moldability and insulation capabilities make it ideal for household goods and medical devices. The contrasting physical and chemical properties of lead and plastic determine their specialized roles in industrial, environmental, and health-related sectors.

Future Trends in Lead and Plastic Alternatives

Future trends in lead alternatives emphasize the development of eco-friendly and non-toxic materials to replace lead in batteries, radiation shielding, and construction. Advances in plastic technologies prioritize biodegradable and recyclable polymers that offer comparable durability and cost-effectiveness while reducing environmental impact. Innovations such as solid-state batteries, bio-based composites, and graphene-enhanced plastics are poised to disrupt traditional lead and plastic applications, driving sustainable industry transformation.

Lead vs Plastic Infographic

materialdif.com

materialdif.com