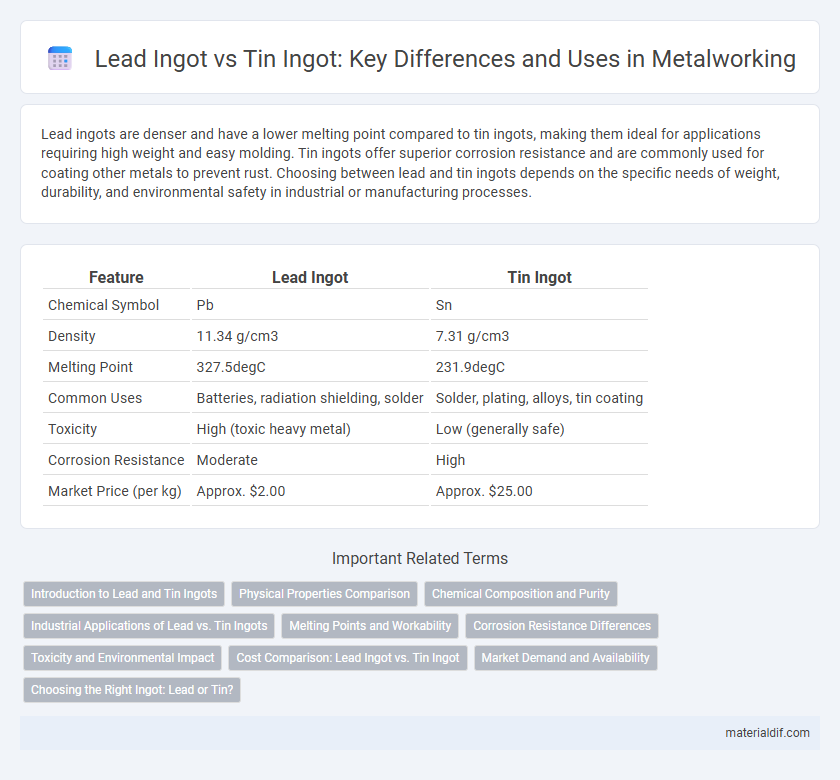

Lead ingots are denser and have a lower melting point compared to tin ingots, making them ideal for applications requiring high weight and easy molding. Tin ingots offer superior corrosion resistance and are commonly used for coating other metals to prevent rust. Choosing between lead and tin ingots depends on the specific needs of weight, durability, and environmental safety in industrial or manufacturing processes.

Table of Comparison

| Feature | Lead Ingot | Tin Ingot |

|---|---|---|

| Chemical Symbol | Pb | Sn |

| Density | 11.34 g/cm3 | 7.31 g/cm3 |

| Melting Point | 327.5degC | 231.9degC |

| Common Uses | Batteries, radiation shielding, solder | Solder, plating, alloys, tin coating |

| Toxicity | High (toxic heavy metal) | Low (generally safe) |

| Corrosion Resistance | Moderate | High |

| Market Price (per kg) | Approx. $2.00 | Approx. $25.00 |

Introduction to Lead and Tin Ingots

Lead ingots, composed primarily of dense lead metal, are widely used in construction, batteries, and radiation shielding due to their high density and malleability. Tin ingots, made from pure tin, are essential in soldering, plating, and alloy production because of their low melting point and corrosion resistance. Both lead and tin ingots serve critical industrial purposes, but their distinct physical and chemical properties determine their specific applications.

Physical Properties Comparison

Lead ingots exhibit higher density at approximately 11.34 g/cm3 compared to tin ingots, which have a density around 7.31 g/cm3. Lead has a melting point of 327.5degC, significantly lower than tin's melting point of 231.9degC, affecting their suitability in different casting processes. While lead is softer with a Vickers hardness of about 5 HV, tin is harder, with a Vickers hardness near 6-7 HV, influencing durability in applications.

Chemical Composition and Purity

Lead ingots typically consist of over 99.9% pure lead (Pb), with minor traces of antimony, arsenic, and tin, enhancing strength and corrosion resistance. Tin ingots are primarily composed of more than 99.8% pure tin (Sn), often containing small amounts of copper and silver to improve mechanical properties. The distinct chemical composition and purity levels directly influence their suitability for applications like soldering, radiation shielding, and alloy manufacturing.

Industrial Applications of Lead vs. Tin Ingots

Lead ingots are extensively used in radiation shielding, batteries, and cable sheathing due to their high density and corrosion resistance, while tin ingots find primary industrial applications in soldering, plating, and alloy production because of their excellent malleability and resistance to oxidation. Industrial demand for lead ingots is driven by the automotive and construction sectors, whereas tin ingots are essential in electronics manufacturing and food packaging. Both metals serve critical roles, but lead's heavy metal characteristics make it irreplaceable in protective applications, contrasting with tin's crucial role in enhancing metal performance and durability.

Melting Points and Workability

Lead ingots have a melting point of 327.5degC, significantly lower than tin ingots, which melt at 231.9degC, making tin easier to melt and cast. Lead offers superior malleability and density, providing better workability for heavy-duty applications, while tin's softness and lower melting point enhance its use in intricate molds and coatings. The choice between lead and tin ingots depends on the required melting temperature and the specific workability needed for the manufacturing process.

Corrosion Resistance Differences

Lead ingots exhibit superior corrosion resistance compared to tin ingots due to lead's stable oxide layer that protects against environmental degradation. Tin ingots are prone to "tin pest" and oxidation under fluctuating temperatures and humidity, reducing their durability. This makes lead ingots more suitable for applications requiring long-term exposure to corrosive or harsh conditions.

Toxicity and Environmental Impact

Lead ingots pose significant toxicity risks due to lead's neurotoxic effects and its persistence in the environment, leading to bioaccumulation and contamination of soil and water. Tin ingots exhibit considerably lower toxicity and environmental impact, as tin is less harmful to human health and degrades more readily in nature. Choosing tin over lead reduces hazardous waste and long-term ecological damage associated with heavy metal pollution.

Cost Comparison: Lead Ingot vs. Tin Ingot

Lead ingots typically cost significantly less than tin ingots due to the abundant availability and lower extraction expenses of lead. Tin ingots command higher prices driven by limited global supply, increased demand in soldering and electronics, and more complex refining processes. Evaluating procurement budgets for industrial manufacturing requires considering these cost disparities to optimize material expenditure effectively.

Market Demand and Availability

Lead ingots exhibit steady market demand primarily driven by the battery manufacturing and construction industries, benefiting from widespread availability due to abundant global reserves and well-established recycling processes. Tin ingots, while facing more limited natural resources, command growing demand in electronics and soldering applications, with market availability influenced by concentrated mining in Southeast Asia and geopolitical factors. Supply chain stability for lead ingots remains relatively robust compared to tin, whose scarcity and logistical challenges often result in price volatility and constrained availability.

Choosing the Right Ingot: Lead or Tin?

Lead ingots offer higher density and better radiation shielding, making them ideal for industrial and construction applications requiring durability and protection. Tin ingots provide superior corrosion resistance and excellent soldering properties, favored in electronics and plating industries. Selecting the right ingot depends on specific project needs for strength, conductivity, and environmental exposure.

Lead ingot vs tin ingot Infographic

materialdif.com

materialdif.com