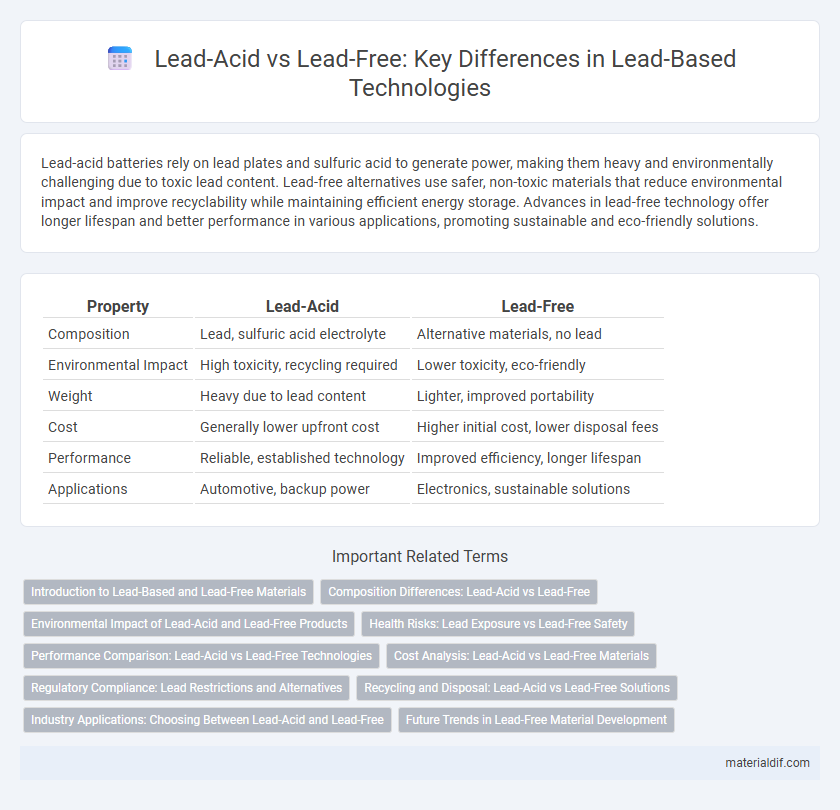

Lead-acid batteries rely on lead plates and sulfuric acid to generate power, making them heavy and environmentally challenging due to toxic lead content. Lead-free alternatives use safer, non-toxic materials that reduce environmental impact and improve recyclability while maintaining efficient energy storage. Advances in lead-free technology offer longer lifespan and better performance in various applications, promoting sustainable and eco-friendly solutions.

Table of Comparison

| Property | Lead-Acid | Lead-Free |

|---|---|---|

| Composition | Lead, sulfuric acid electrolyte | Alternative materials, no lead |

| Environmental Impact | High toxicity, recycling required | Lower toxicity, eco-friendly |

| Weight | Heavy due to lead content | Lighter, improved portability |

| Cost | Generally lower upfront cost | Higher initial cost, lower disposal fees |

| Performance | Reliable, established technology | Improved efficiency, longer lifespan |

| Applications | Automotive, backup power | Electronics, sustainable solutions |

Introduction to Lead-Based and Lead-Free Materials

Lead-based materials, primarily lead-acid batteries, utilize lead dioxide and sponge lead electrodes, offering high energy density and reliable performance in automotive and industrial applications. Lead-free alternatives, such as lithium-ion and nickel-metal hydride batteries, eliminate toxic lead content, promoting environmental sustainability and compliance with stringent regulations. The choice between lead-based and lead-free materials hinges on balancing performance metrics with ecological impact and regulatory requirements.

Composition Differences: Lead-Acid vs Lead-Free

Lead-acid batteries contain a lead dioxide cathode, a lead anode, and sulfuric acid electrolyte, relying on lead-based chemical reactions for energy storage. Lead-free batteries utilize alternative materials such as lithium-ion, nickel-metal hydride, or sodium-ion chemistries, eliminating toxic lead components. These composition differences affect battery weight, environmental impact, and recycling processes, with lead-free options offering safer and more sustainable alternatives.

Environmental Impact of Lead-Acid and Lead-Free Products

Lead-free products significantly reduce environmental contamination by eliminating toxic lead emissions and hazardous waste associated with lead-acid batteries. Lead-acid batteries contribute to soil and water pollution through lead leakage and improper disposal, posing serious health risks to ecosystems and human populations. Transitioning to lead-free alternatives promotes sustainable waste management and decreases ecological footprint in battery manufacturing and recycling processes.

Health Risks: Lead Exposure vs Lead-Free Safety

Lead-acid batteries pose significant health risks due to prolonged exposure to lead, which can cause neurological damage, kidney problems, and reproductive issues. Lead-free alternatives eliminate these toxic hazards, offering safer handling and disposal without compromising battery performance. Industries and consumers benefit from reduced environmental contamination and enhanced occupational safety by switching to lead-free technology.

Performance Comparison: Lead-Acid vs Lead-Free Technologies

Lead-acid batteries provide reliable high current output and superior cold weather performance, making them ideal for automotive and backup power applications. Lead-free battery technologies, often based on lithium-ion or advanced polymer chemistries, offer higher energy density, faster charging times, and longer cycle life, significantly enhancing overall efficiency and weight reduction. Despite lead-free options excelling in longevity and environmental impact, lead-acid batteries remain preferred for cost-effective, heavy-duty performance in traditional energy storage scenarios.

Cost Analysis: Lead-Acid vs Lead-Free Materials

Lead-acid batteries typically offer lower upfront costs compared to lead-free alternatives, making them a cost-effective choice for many traditional applications. Lead-free materials, such as lithium-ion or advanced polymer composites, involve higher initial investments but provide longer lifespans and reduced maintenance expenses, potentially lowering total cost of ownership over time. Evaluating both material cost and lifecycle expenses is crucial for determining the most economical option for specific energy storage needs.

Regulatory Compliance: Lead Restrictions and Alternatives

Regulatory compliance increasingly restricts the use of lead in products due to its toxicity and environmental impact, prompting industries to seek lead-free alternatives. Lead-acid batteries, widely used in automotive and industrial applications, face stringent regulations like RoHS and REACH that limit lead content to protect human health and the environment. Alternatives such as lithium-ion and nickel-metal hydride batteries provide eco-friendly options that comply with lead restriction policies while maintaining performance standards.

Recycling and Disposal: Lead-Acid vs Lead-Free Solutions

Lead-acid batteries require specialized recycling processes due to their high lead content, enabling effective lead recovery but posing environmental hazards if improperly disposed of. Lead-free alternatives, often based on lithium or other chemistries, present simpler recycling challenges with less toxic material but currently face limitations in established recycling infrastructure. Efficient disposal and recycling frameworks are essential for both types to minimize environmental impact and promote sustainability in battery lifecycle management.

Industry Applications: Choosing Between Lead-Acid and Lead-Free

Lead-acid batteries are extensively used in automotive, backup power, and industrial applications due to their cost-effectiveness and high surge current capabilities. Lead-free alternatives, such as lithium-ion and nickel-metal hydride batteries, are preferred in electronics and renewable energy sectors for their lighter weight, longer cycle life, and environmental compliance. Industry decision-makers prioritize lead-acid for heavy-duty requirements, while lead-free options dominate markets demanding sustainability and reduced hazardous waste.

Future Trends in Lead-Free Material Development

Future trends in lead-free material development emphasize enhancing battery efficiency, safety, and environmental sustainability by exploring alternatives such as lithium-ion, sodium-ion, and solid-state technologies. Researchers are improving electrochemical performance and recyclability to meet regulatory demands and reduce toxic lead usage. Innovations in nanomaterials and advanced manufacturing processes are driving the shift towards greener, high-capacity energy storage solutions beyond traditional lead-acid batteries.

Lead-acid vs Lead-free Infographic

materialdif.com

materialdif.com