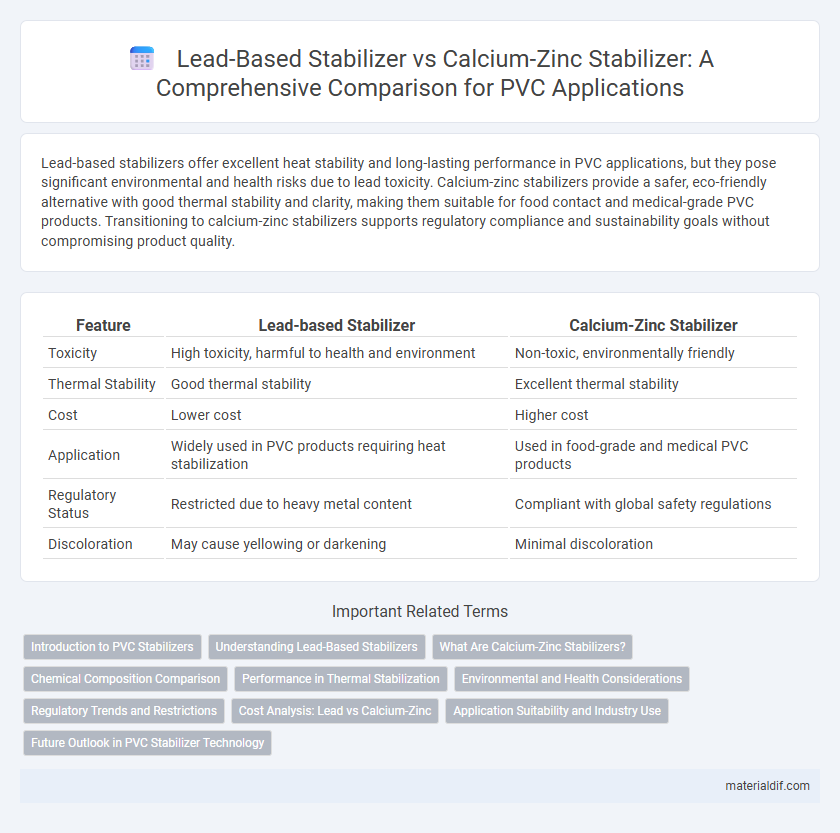

Lead-based stabilizers offer excellent heat stability and long-lasting performance in PVC applications, but they pose significant environmental and health risks due to lead toxicity. Calcium-zinc stabilizers provide a safer, eco-friendly alternative with good thermal stability and clarity, making them suitable for food contact and medical-grade PVC products. Transitioning to calcium-zinc stabilizers supports regulatory compliance and sustainability goals without compromising product quality.

Table of Comparison

| Feature | Lead-based Stabilizer | Calcium-Zinc Stabilizer |

|---|---|---|

| Toxicity | High toxicity, harmful to health and environment | Non-toxic, environmentally friendly |

| Thermal Stability | Good thermal stability | Excellent thermal stability |

| Cost | Lower cost | Higher cost |

| Application | Widely used in PVC products requiring heat stabilization | Used in food-grade and medical PVC products |

| Regulatory Status | Restricted due to heavy metal content | Compliant with global safety regulations |

| Discoloration | May cause yellowing or darkening | Minimal discoloration |

Introduction to PVC Stabilizers

PVC stabilizers are essential additives that enhance the heat stability and longevity of polyvinyl chloride products. Lead-based stabilizers offer excellent processing stability and cost-effectiveness but face regulatory restrictions due to toxicity concerns. Calcium-zinc stabilizers provide a non-toxic alternative with good thermal stability, making them suitable for food contact applications and environmentally sensitive markets.

Understanding Lead-Based Stabilizers

Lead-based stabilizers provide excellent heat stability and durability in PVC products, ensuring enhanced resistance to thermal degradation and discoloration during processing. Their superior performance in long-term weathering and mechanical strength makes them a preferred choice in industrial applications requiring high reliability. However, environmental and health concerns have driven increased regulation and a gradual shift towards alternative stabilizers like calcium-zinc systems.

What Are Calcium-Zinc Stabilizers?

Calcium-zinc stabilizers are eco-friendly additives used in PVC processing to enhance heat stability and prevent degradation. Unlike lead-based stabilizers, calcium-zinc stabilizers offer non-toxic properties and superior resistance to weathering, making them ideal for applications requiring durability and environmental compliance. These stabilizers improve clarity and mechanical properties in PVC products while eliminating the health and environmental risks associated with lead-based alternatives.

Chemical Composition Comparison

Lead-based stabilizers primarily consist of lead salts such as lead sulfate, lead stearate, and lead carbonate, which provide effective heat stability and lubrication in PVC applications. Calcium-zinc stabilizers are composed of calcium stearate, zinc stearate, and other calcium and zinc salts, offering a non-toxic alternative with good thermal stability and light resistance. The chemical composition difference impacts environmental safety, with calcium-zinc stabilizers favored for lead-free, eco-friendly PVC production.

Performance in Thermal Stabilization

Lead-based stabilizers exhibit superior performance in thermal stabilization due to their strong resistance to heat degradation, ensuring prolonged material integrity and color retention in PVC applications. Calcium-zinc stabilizers offer excellent thermal stability with enhanced environmental safety, but may present slightly lower durability under high-temperature conditions. The choice between lead-based and calcium-zinc stabilizers depends on balancing thermal performance requirements with regulatory and health considerations.

Environmental and Health Considerations

Lead-based stabilizers release toxic lead particles during processing and disposal, posing significant environmental contamination and serious health risks such as neurological damage. Calcium-zinc stabilizers offer an eco-friendly alternative, providing effective thermal stability without harmful heavy metal emissions. Their biodegradable nature and lower toxicity contribute to safer manufacturing conditions and reduced environmental impact.

Regulatory Trends and Restrictions

Lead-based stabilizers face increasingly stringent regulatory restrictions worldwide due to their toxicity and environmental impact, with many regions implementing bans or severe usage limitations. Calcium-zinc stabilizers are rapidly gaining preference as a safer, non-toxic alternative compliant with regulations such as REACH in Europe and RoHS directives globally. Regulatory trends favor calcium-zinc systems for their improved environmental profile and alignment with sustainability goals in plastic stabilization.

Cost Analysis: Lead vs Calcium-Zinc

Lead-based stabilizers generally offer lower initial costs compared to calcium-zinc stabilizers, making them economically attractive for large-scale PVC production. Calcium-zinc stabilizers, while more expensive upfront, reduce long-term environmental compliance and disposal costs due to their non-toxic nature. Cost analysis must consider regulatory trends and potential liabilities favoring calcium-zinc despite higher material expenses.

Application Suitability and Industry Use

Lead-based stabilizers are widely used in applications requiring excellent heat stability and long-term durability, commonly found in automotive and construction industries for rigid PVC products. Calcium-zinc stabilizers offer superior environmental compliance and are preferred in food packaging, medical devices, and children's toys due to their non-toxic nature and effective thermal stabilization. The choice between lead-based and calcium-zinc stabilizers depends on regulatory standards and end-use safety requirements in diverse industrial sectors.

Future Outlook in PVC Stabilizer Technology

Lead-based stabilizers, historically favored for their effectiveness in PVC applications, face declining usage due to environmental and health concerns driving regulatory restrictions worldwide. Calcium-zinc stabilizers are increasingly adopted as eco-friendly alternatives, offering comparable thermal stability and improved compatibility with green manufacturing processes. Future PVC stabilizer technology will prioritize sustainable, non-toxic formulations with enhanced performance to meet stringent regulations and growing demand for environmentally responsible materials.

Lead-based stabilizer vs Calcium-zinc stabilizer Infographic

materialdif.com

materialdif.com