Lead shielding offers effective radiation protection due to its high density and affordability, commonly used in medical and industrial applications. Tungsten shielding provides superior durability and higher radiation attenuation in compact forms, ideal for environments requiring lightweight and corrosion-resistant materials. Choosing between lead and tungsten shielding depends on factors like weight limitations, budget, and specific radiation exposure requirements.

Table of Comparison

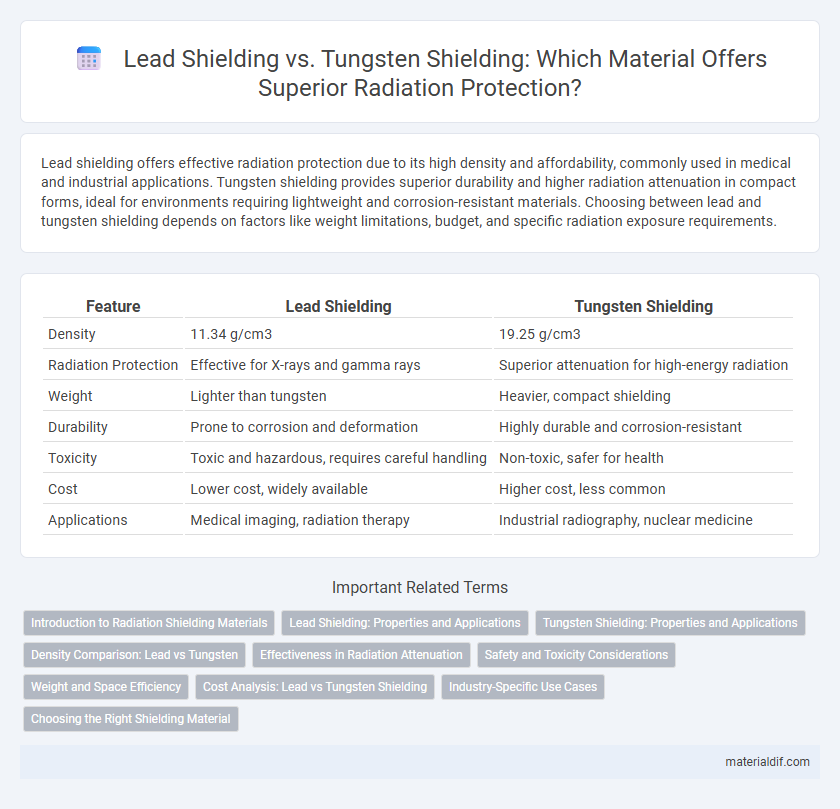

| Feature | Lead Shielding | Tungsten Shielding |

|---|---|---|

| Density | 11.34 g/cm3 | 19.25 g/cm3 |

| Radiation Protection | Effective for X-rays and gamma rays | Superior attenuation for high-energy radiation |

| Weight | Lighter than tungsten | Heavier, compact shielding |

| Durability | Prone to corrosion and deformation | Highly durable and corrosion-resistant |

| Toxicity | Toxic and hazardous, requires careful handling | Non-toxic, safer for health |

| Cost | Lower cost, widely available | Higher cost, less common |

| Applications | Medical imaging, radiation therapy | Industrial radiography, nuclear medicine |

Introduction to Radiation Shielding Materials

Lead shielding offers effective protection against a wide range of ionizing radiation due to its high density and atomic number, making it a traditional choice in medical and industrial applications. Tungsten shielding provides a more compact alternative with superior attenuation properties, especially for high-energy radiation, and is favored in environments where space and weight are critical factors. Both materials serve crucial roles in radiation shielding, with selection depending on specific shielding requirements, including radiation type, energy levels, and application constraints.

Lead Shielding: Properties and Applications

Lead shielding offers high density and excellent radiation attenuation, making it a preferred material in medical radiology, nuclear power plants, and industrial radiography. Its malleability allows for easy fabrication into various shapes and thicknesses tailored for specific protection levels. While tungsten shielding provides higher melting points and strength, lead remains more cost-effective and easier to install for comprehensive gamma and X-ray radiation shielding.

Tungsten Shielding: Properties and Applications

Tungsten shielding offers superior density and high atomic number, providing excellent attenuation of gamma rays and X-rays compared to traditional lead shielding. Its non-toxic and eco-friendly nature makes it ideal for medical imaging, nuclear power plants, and aerospace applications requiring robust radiation protection. The metal's high melting point and mechanical strength ensure durability in extreme environments, enhancing safety and performance across diverse industries.

Density Comparison: Lead vs Tungsten

Lead has a density of approximately 11.34 grams per cubic centimeter, making it a traditional choice for radiation shielding due to its high mass per volume. Tungsten's density is significantly higher, around 19.25 grams per cubic centimeter, providing superior attenuation of radiation with thinner shielding thickness compared to lead. This higher density of tungsten allows for more compact and efficient shielding solutions in medical, industrial, and nuclear applications.

Effectiveness in Radiation Attenuation

Lead shielding demonstrates superior effectiveness in radiation attenuation due to its high atomic number (82) and density (11.34 g/cm3), which enable efficient absorption of gamma rays and X-rays. Tungsten, with an atomic number of 74 and a density of 19.25 g/cm3, offers enhanced attenuation for high-energy photons despite being less commonly used. The choice between lead and tungsten shielding depends on application-specific factors such as radiation energy, weight constraints, and cost considerations, with tungsten providing better protection at higher energies and lead excelling in general radiation shielding scenarios.

Safety and Toxicity Considerations

Lead shielding provides effective radiation protection but raises significant safety concerns due to its high toxicity and potential for lead poisoning during manufacturing and disposal. Tungsten shielding offers a safer alternative with similar radiation attenuation properties and lower health risks, as tungsten is less toxic and more environmentally stable. Choosing tungsten reduces hazardous exposure for workers and end-users, making it preferable in medical and industrial applications demanding stringent safety standards.

Weight and Space Efficiency

Tungsten shielding offers superior weight and space efficiency compared to traditional lead shielding, as tungsten's higher density allows for thinner, more compact barriers without compromising protection. Due to its greater density, tungsten reduces overall shielding thickness, making it ideal for applications requiring lightweight, space-saving solutions such as aerospace and medical imaging. Although tungsten is generally more expensive, its benefits in minimizing weight and spatial footprint outweigh the cost in environments where size and weight constraints are critical.

Cost Analysis: Lead vs Tungsten Shielding

Lead shielding offers a cost-effective solution due to its lower raw material price and ease of manufacturing compared to tungsten shielding. Tungsten provides superior radiation attenuation and durability but incurs higher expenses driven by material rarity and processing complexity. Evaluating the total cost of ownership reveals lead as the budget-friendly choice for standard applications, while tungsten justifies its premium cost in high-performance or space-constrained environments.

Industry-Specific Use Cases

Lead shielding remains the preferred material in medical radiology and nuclear power plants due to its high density and cost-effectiveness for blocking gamma rays and X-rays. Tungsten shielding, favored in aerospace and military applications, offers superior strength, corrosion resistance, and a higher melting point, making it ideal for environments requiring lightweight, durable protection against radiation. Industry-specific factors like exposure type, weight constraints, and budget dictate the choice between lead and tungsten for effective radiation shielding solutions.

Choosing the Right Shielding Material

When choosing the right shielding material, lead provides excellent radiation attenuation due to its high density and cost-effectiveness, making it ideal for standard medical and industrial applications. Tungsten shielding, though more expensive, offers superior durability and higher radiation absorption in compact thicknesses, making it suitable for high-precision uses, including aerospace and nuclear industries. Consider factors like radiation type, weight constraints, space limitations, and budget to select between lead's affordability and tungsten's performance advantages.

Lead Shielding vs Tungsten Shielding Infographic

materialdif.com

materialdif.com