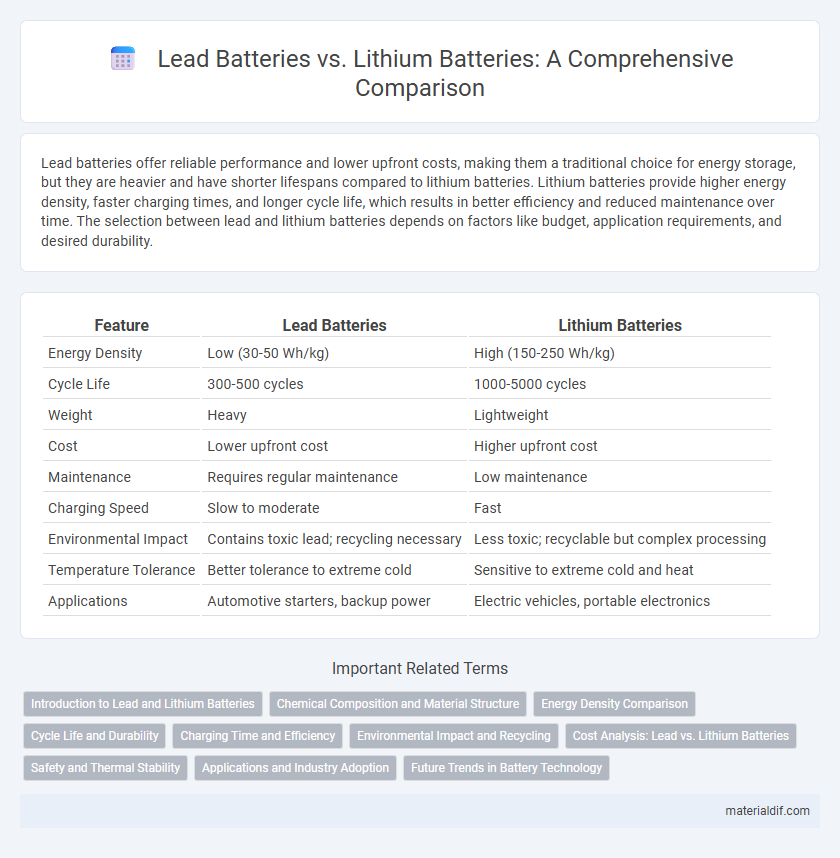

Lead batteries offer reliable performance and lower upfront costs, making them a traditional choice for energy storage, but they are heavier and have shorter lifespans compared to lithium batteries. Lithium batteries provide higher energy density, faster charging times, and longer cycle life, which results in better efficiency and reduced maintenance over time. The selection between lead and lithium batteries depends on factors like budget, application requirements, and desired durability.

Table of Comparison

| Feature | Lead Batteries | Lithium Batteries |

|---|---|---|

| Energy Density | Low (30-50 Wh/kg) | High (150-250 Wh/kg) |

| Cycle Life | 300-500 cycles | 1000-5000 cycles |

| Weight | Heavy | Lightweight |

| Cost | Lower upfront cost | Higher upfront cost |

| Maintenance | Requires regular maintenance | Low maintenance |

| Charging Speed | Slow to moderate | Fast |

| Environmental Impact | Contains toxic lead; recycling necessary | Less toxic; recyclable but complex processing |

| Temperature Tolerance | Better tolerance to extreme cold | Sensitive to extreme cold and heat |

| Applications | Automotive starters, backup power | Electric vehicles, portable electronics |

Introduction to Lead and Lithium Batteries

Lead batteries, also known as lead-acid batteries, utilize lead dioxide and sponge lead plates immersed in sulfuric acid to store and release electrical energy, offering reliable performance in automotive starters and backup power systems due to their low cost and robust design. Lithium batteries, typically lithium-ion or lithium polymer, employ lithium compounds and electrolytes to achieve higher energy density, longer cycle life, and lighter weight, making them ideal for portable electronics, electric vehicles, and renewable energy storage. Advances in lithium battery technology have significantly improved charge efficiency and safety, gradually surpassing the traditional lead-acid batteries in various applications.

Chemical Composition and Material Structure

Lead batteries utilize lead dioxide (PbO2) for the positive plate and sponge lead (Pb) for the negative plate, with sulfuric acid as the electrolyte, forming a dense, heavy structure optimized for high surge currents. Lithium batteries typically employ lithium cobalt oxide (LiCoO2) or lithium iron phosphate (LiFePO4) as cathode materials and graphite as the anode, featuring a lightweight, layered material structure that enables higher energy density. The chemical composition of lead batteries results in slower charge rates and lower cycle life compared to the electrochemically active materials in lithium batteries, which facilitate faster charging and longer operational lifespan.

Energy Density Comparison

Lead batteries typically have an energy density ranging from 30 to 50 Wh/kg, making them significantly heavier and bulkier compared to lithium batteries, which offer energy densities between 150 and 250 Wh/kg. This difference in energy density means lithium batteries provide longer runtimes and more efficient power storage in lighter, more compact designs, ideal for applications requiring portability and high energy output. The superior energy density of lithium batteries results in better performance for electric vehicles, portable electronics, and renewable energy storage systems, where weight and space are critical factors.

Cycle Life and Durability

Lead batteries typically offer a cycle life ranging from 300 to 500 cycles, whereas lithium batteries can achieve 2,000 to 5,000 cycles, significantly enhancing overall durability. Lithium batteries maintain consistent performance over a longer lifespan due to higher energy density and better resistance to deep discharges. The superior cycle life and durability of lithium batteries make them more cost-effective and reliable for long-term energy storage solutions.

Charging Time and Efficiency

Lead batteries typically have longer charging times, often requiring 8 to 12 hours for a full charge, while lithium batteries can charge fully in 1 to 4 hours due to higher energy density and advanced charging technology. Lithium batteries exhibit greater efficiency with higher charge retention and less energy loss during charging cycles, resulting in improved overall performance compared to lead batteries. The faster charging capability and better efficiency of lithium batteries make them ideal for applications demanding quick turnaround and extended battery life.

Environmental Impact and Recycling

Lead batteries contain toxic lead and sulfuric acid, posing significant environmental hazards if improperly disposed, but their recycling rates exceed 95%, making lead recycling highly efficient and reducing landfill waste. Lithium batteries have lower toxicity but involve complex recycling processes with currently lower recovery rates, leading to environmental challenges from mining and disposal of lithium, cobalt, and nickel components. Advances in lithium battery recycling technology are crucial for minimizing ecological impact and promoting sustainable resource use in electric vehicle and energy storage markets.

Cost Analysis: Lead vs. Lithium Batteries

Lead batteries typically have a lower upfront cost compared to lithium batteries, making them more accessible for budget-conscious applications. However, lithium batteries offer a longer lifespan and higher energy density, reducing total cost of ownership over time despite their higher initial price. Maintenance and replacement expenses for lead batteries often increase the overall cost, while lithium battery technology minimizes these additional costs through enhanced durability and efficiency.

Safety and Thermal Stability

Lead batteries offer robust safety with a lower risk of thermal runaway due to their stable chemical composition and sealed design, making them less prone to overheating. Lithium batteries, while providing higher energy density, require advanced thermal management systems to prevent overheating and potential fire hazards caused by thermal runaway. Effective cooling mechanisms and battery management systems are essential in lithium batteries to ensure thermal stability and enhance overall operational safety.

Applications and Industry Adoption

Lead batteries dominate in automotive starter systems and large-scale energy storage due to their cost-effectiveness and robustness, particularly in backup power and uninterruptible power supplies (UPS). Lithium batteries, favored in consumer electronics, electric vehicles, and renewable energy storage, offer higher energy density, longer lifecycle, and faster charging capabilities, driving rapid adoption in tech-driven industries. Industrial sectors transitioning to sustainable energy solutions increasingly prefer lithium batteries for their superior performance metrics despite higher initial costs.

Future Trends in Battery Technology

Future trends in battery technology emphasize the shift from lead-acid to lithium-ion batteries due to lithium's higher energy density, longer lifespan, and faster charging capabilities. Advances in solid-state lithium batteries promise enhanced safety and durability, potentially surpassing lead batteries in cost-effectiveness as production scales. Innovations in recycling processes and raw material sourcing for lithium also contribute to the sustainability and economic feasibility of lithium battery adoption in various industries.

Lead batteries vs Lithium batteries Infographic

materialdif.com

materialdif.com