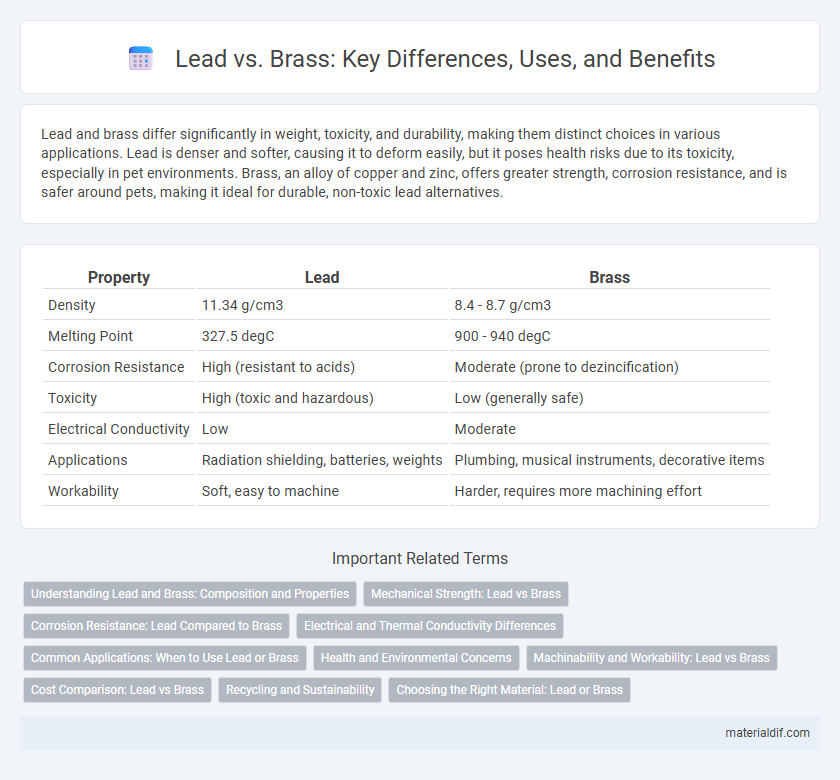

Lead and brass differ significantly in weight, toxicity, and durability, making them distinct choices in various applications. Lead is denser and softer, causing it to deform easily, but it poses health risks due to its toxicity, especially in pet environments. Brass, an alloy of copper and zinc, offers greater strength, corrosion resistance, and is safer around pets, making it ideal for durable, non-toxic lead alternatives.

Table of Comparison

| Property | Lead | Brass |

|---|---|---|

| Density | 11.34 g/cm3 | 8.4 - 8.7 g/cm3 |

| Melting Point | 327.5 degC | 900 - 940 degC |

| Corrosion Resistance | High (resistant to acids) | Moderate (prone to dezincification) |

| Toxicity | High (toxic and hazardous) | Low (generally safe) |

| Electrical Conductivity | Low | Moderate |

| Applications | Radiation shielding, batteries, weights | Plumbing, musical instruments, decorative items |

| Workability | Soft, easy to machine | Harder, requires more machining effort |

Understanding Lead and Brass: Composition and Properties

Lead primarily consists of a dense, malleable metal with a high atomic number of 82, known for its low melting point and excellent corrosion resistance. Brass is an alloy composed mainly of copper and zinc, offering superior strength, ductility, and a lower density compared to lead. The distinct compositions result in differing physical properties: lead is softer and heavier, while brass provides enhanced durability and better conductivity.

Mechanical Strength: Lead vs Brass

Lead exhibits significantly lower mechanical strength compared to brass, making it more prone to deformation under stress. Brass, an alloy of copper and zinc, offers enhanced tensile strength and durability, suitable for applications requiring structural integrity. The higher hardness and yield strength of brass result in superior resistance to wear and mechanical load relative to lead.

Corrosion Resistance: Lead Compared to Brass

Lead exhibits superior corrosion resistance compared to brass, especially in environments with acidic or saline conditions. Unlike brass, which can undergo dezincification and tarnishing, lead forms a stable oxide layer that protects it from further degradation. This inherent corrosion resistance makes lead a preferred choice for applications requiring prolonged exposure to harsh chemicals or moisture.

Electrical and Thermal Conductivity Differences

Lead exhibits significantly lower electrical and thermal conductivity compared to brass, making it less efficient for applications requiring rapid energy transfer. Brass, an alloy of copper and zinc, offers a conductivity that is approximately 24% IACS (International Annealed Copper Standard) for electrical and around 109 W/m*K for thermal conductivity. These differences influence material selection in electrical components and heat exchangers, where brass typically outperforms lead due to its superior conductivity properties.

Common Applications: When to Use Lead or Brass

Lead is preferred in applications requiring high corrosion resistance and weight, such as radiation shielding, batteries, and cable sheathing. Brass offers superior machinability and aesthetic appeal, making it ideal for decorative fittings, plumbing components, and musical instruments. Selecting lead or brass depends on factors like environmental exposure, mechanical strength, and electrical conductivity.

Health and Environmental Concerns

Lead exposure poses significant health risks, including neurological damage and developmental delays, particularly in children, while brass, an alloy primarily of copper and zinc, is less toxic but can still release harmful metals like lead or nickel depending on its composition. Environmental concerns about lead highlight its persistence in soil and water, leading to bioaccumulation and ecosystem damage, whereas brass corrodes more slowly and is often recycled to minimize ecological impact. Proper handling and disposal protocols are essential to mitigate lead contamination, contrasting with brass's comparatively lower but still notable environmental footprint.

Machinability and Workability: Lead vs Brass

Lead exhibits superior machinability compared to brass due to its lower melting point and softer nature, allowing easier cutting and shaping with minimal tool wear. Brass offers better workability for applications requiring higher strength and corrosion resistance, but its harder composition demands more robust machining equipment. Both materials serve distinct functions where lead excels in precision machining and brass is preferred for durable, decorative, and structural components.

Cost Comparison: Lead vs Brass

Lead is significantly cheaper than brass, making it a cost-effective choice for applications requiring mass production or bulk material usage. Brass, an alloy of copper and zinc, commands a higher price due to its superior strength, corrosion resistance, and aesthetic appeal. When comparing costs, lead's lower market price and ease of processing often outweigh the higher initial investment in brass for budget-sensitive projects.

Recycling and Sustainability

Lead offers a higher recycling rate compared to brass, with approximately 85% to 90% of lead being recycled globally, which significantly reduces the environmental impact of mining. Brass recycling also contributes to sustainability but typically involves a more energy-intensive process due to its alloy composition and lower recycling efficiency. Efficient lead recycling programs support circular economy principles by minimizing hazardous waste and conserving natural resources more effectively than brass recycling initiatives.

Choosing the Right Material: Lead or Brass

Lead offers superior malleability and excellent radiation shielding, making it ideal for applications requiring easy shaping and protection from radiation exposure. Brass provides higher tensile strength, enhanced corrosion resistance, and better aesthetic appeal, suitable for structural components and decorative purposes. Selecting between lead and brass depends on prioritizing factors like durability, weight, toxicity, and environmental impact in the specific use case.

Lead vs Brass Infographic

materialdif.com

materialdif.com