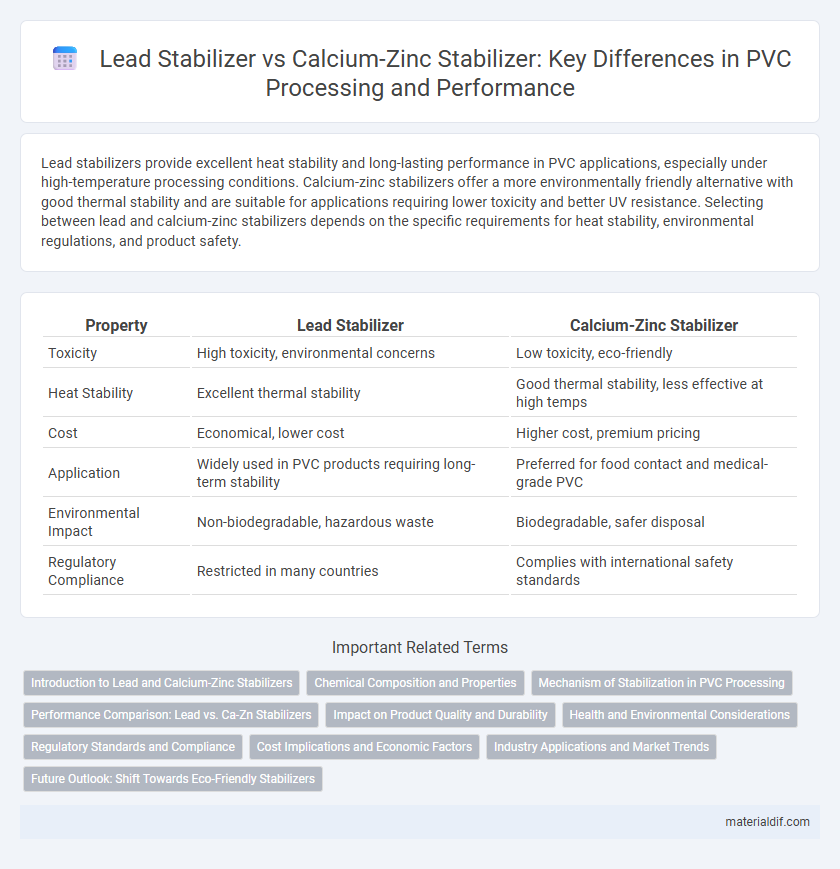

Lead stabilizers provide excellent heat stability and long-lasting performance in PVC applications, especially under high-temperature processing conditions. Calcium-zinc stabilizers offer a more environmentally friendly alternative with good thermal stability and are suitable for applications requiring lower toxicity and better UV resistance. Selecting between lead and calcium-zinc stabilizers depends on the specific requirements for heat stability, environmental regulations, and product safety.

Table of Comparison

| Property | Lead Stabilizer | Calcium-Zinc Stabilizer |

|---|---|---|

| Toxicity | High toxicity, environmental concerns | Low toxicity, eco-friendly |

| Heat Stability | Excellent thermal stability | Good thermal stability, less effective at high temps |

| Cost | Economical, lower cost | Higher cost, premium pricing |

| Application | Widely used in PVC products requiring long-term stability | Preferred for food contact and medical-grade PVC |

| Environmental Impact | Non-biodegradable, hazardous waste | Biodegradable, safer disposal |

| Regulatory Compliance | Restricted in many countries | Complies with international safety standards |

Introduction to Lead and Calcium-Zinc Stabilizers

Lead stabilizers are traditional additives widely used in PVC processing to enhance thermal stability and prevent degradation during manufacturing. Calcium-zinc stabilizers serve as an eco-friendly alternative, offering effective heat stabilization without the environmental and health risks associated with lead. Both stabilizers improve PVC durability, but calcium-zinc variants provide superior corrosion resistance and compliance with stringent regulatory standards.

Chemical Composition and Properties

Lead stabilizers primarily consist of lead salts, such as lead stearate, which provide excellent thermal stability and are highly effective in preventing PVC degradation by scavenging hydrogen chloride. Calcium-zinc stabilizers feature a combination of calcium and zinc salts, offering enhanced environmental compatibility and resistance to discoloration by forming metal-carboxylate complexes that inhibit polymer chain breakdown. The chemical composition of lead stabilizers confers superior heat stability and weathering resistance, while calcium-zinc stabilizers deliver better transparency, non-toxicity, and compliance with regulations on heavy metal content.

Mechanism of Stabilization in PVC Processing

Lead stabilizers function by forming strong coordination bonds with the chlorine atoms in PVC, replacing unstable chlorine sites and preventing dehydrochlorination that leads to discoloration and degradation. Calcium-zinc stabilizers operate through a dual mechanism involving the scavenging of hydrochloric acid with calcium compounds and the stabilization of labile chloride sites by zinc complexes, which together enhance thermal stability without heavy metal toxicity. Both stabilizers inhibit the autodegradation process during PVC processing by maintaining the polymer's structural integrity and color stability under heat exposure.

Performance Comparison: Lead vs. Ca-Zn Stabilizers

Lead stabilizers exhibit excellent heat stability and processing performance, making them suitable for demanding applications requiring long-term thermal resistance. Calcium-zinc stabilizers offer better environmental profiles and improved clarity in finished products but may demonstrate slightly lower thermal stability under high-temperature conditions. Performance comparison highlights that lead stabilizers outperform Ca-Zn stabilizers in durability and effectiveness during extended heat exposure, while Ca-Zn stabilizers provide a safer alternative with sufficient stability for many medium-heat processing applications.

Impact on Product Quality and Durability

Lead stabilizers provide excellent heat stability and long-term durability in PVC products, ensuring resistance to discoloration and degradation under high temperatures. Calcium-zinc stabilizers offer superior environmental safety and enhance surface clarity but may exhibit slightly lower thermal stability compared to lead-based alternatives. Selecting the appropriate stabilizer depends on balancing product longevity requirements with regulatory and environmental considerations.

Health and Environmental Considerations

Lead stabilizers release toxic lead compounds that pose significant health risks such as neurotoxicity and accumulation in the environment, leading to long-term soil and water contamination. Calcium-zinc stabilizers provide a safer alternative with lower toxicity, reducing hazardous emissions and minimizing environmental impact during PVC processing. Health and environmental regulations increasingly favor calcium-zinc stabilizers due to their non-toxic properties and improved ecological compatibility compared to lead-based counterparts.

Regulatory Standards and Compliance

Lead stabilizers are heavily restricted under international regulatory standards due to their toxicity and environmental impact, with regulations like the EU RoHS Directive limiting their use in consumer products. Calcium-zinc stabilizers are increasingly preferred as compliant alternatives, meeting stringent global environmental regulations while providing effective thermal stability in PVC applications. Compliance with standards such as REACH and TSCA further drives the adoption of calcium-zinc stabilizers in industries demanding safer and eco-friendly stabilizing solutions.

Cost Implications and Economic Factors

Lead stabilizers generally offer lower initial costs compared to calcium-zinc stabilizers, making them economically attractive for large-scale applications in PVC processing. Calcium-zinc stabilizers, while more expensive upfront, reduce long-term expenses by enhancing product durability and minimizing environmental compliance costs due to their non-toxicity. Evaluating total cost of ownership, including health, safety, and environmental regulations, often reveals calcium-zinc stabilizers as a cost-effective solution despite higher material prices.

Industry Applications and Market Trends

Lead stabilizers dominate in heavy-duty PVC applications due to their superior heat stability and cost-effectiveness, especially in construction and automotive sectors. Calcium-zinc stabilizers are gaining traction in food packaging, medical devices, and child-safe products because of their non-toxic, environmentally friendly profile driving regulatory compliance. Market trends indicate a steady shift towards calcium-zinc stabilizers driven by stringent environmental regulations and increasing demand for sustainable materials in emerging economies.

Future Outlook: Shift Towards Eco-Friendly Stabilizers

The future outlook in the PVC stabilization market indicates a significant shift towards eco-friendly stabilizers, with calcium-zinc stabilizers gaining prominence due to their lower toxicity compared to traditional lead stabilizers. Regulatory pressure and increasing environmental awareness are driving manufacturers to adopt calcium-zinc systems that offer excellent heat stability and color retention while minimizing health and environmental risks. As the demand for sustainable construction materials rises, calcium-zinc stabilizers are expected to capture a larger market share, promoting greener production processes and compliance with stringent global standards.

Lead stabilizer vs Calcium-zinc stabilizer Infographic

materialdif.com

materialdif.com