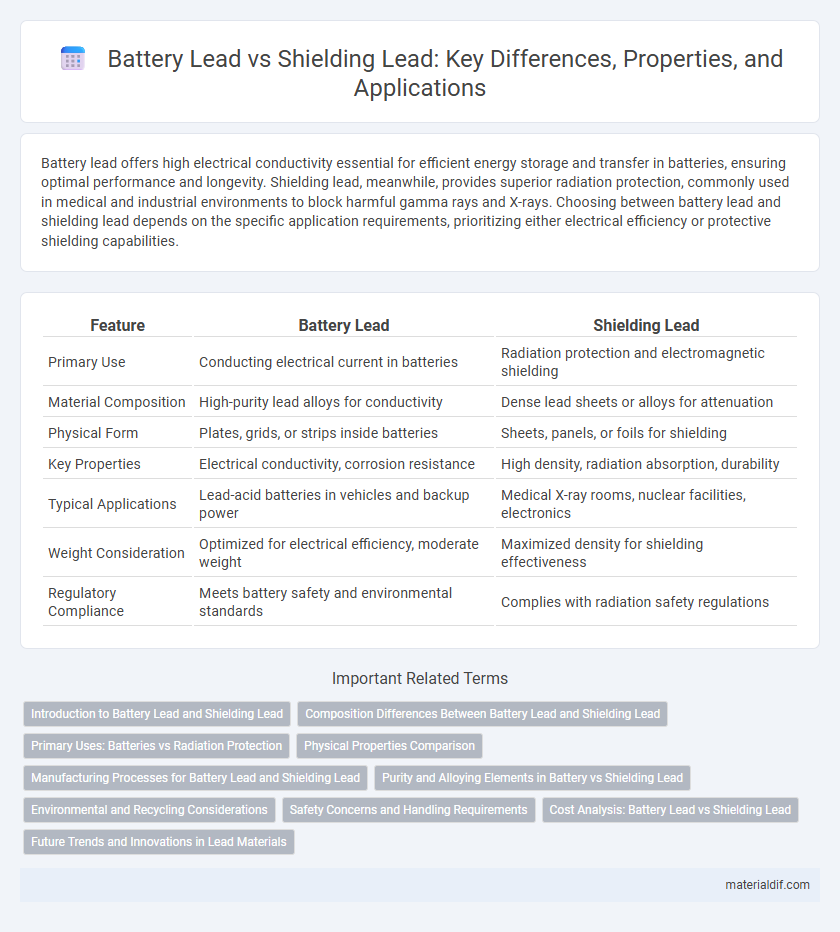

Battery lead offers high electrical conductivity essential for efficient energy storage and transfer in batteries, ensuring optimal performance and longevity. Shielding lead, meanwhile, provides superior radiation protection, commonly used in medical and industrial environments to block harmful gamma rays and X-rays. Choosing between battery lead and shielding lead depends on the specific application requirements, prioritizing either electrical efficiency or protective shielding capabilities.

Table of Comparison

| Feature | Battery Lead | Shielding Lead |

|---|---|---|

| Primary Use | Conducting electrical current in batteries | Radiation protection and electromagnetic shielding |

| Material Composition | High-purity lead alloys for conductivity | Dense lead sheets or alloys for attenuation |

| Physical Form | Plates, grids, or strips inside batteries | Sheets, panels, or foils for shielding |

| Key Properties | Electrical conductivity, corrosion resistance | High density, radiation absorption, durability |

| Typical Applications | Lead-acid batteries in vehicles and backup power | Medical X-ray rooms, nuclear facilities, electronics |

| Weight Consideration | Optimized for electrical efficiency, moderate weight | Maximized density for shielding effectiveness |

| Regulatory Compliance | Meets battery safety and environmental standards | Complies with radiation safety regulations |

Introduction to Battery Lead and Shielding Lead

Battery lead is a highly conductive material primarily used in lead-acid batteries to store and deliver electrical energy efficiently, ensuring reliable power for automotive and industrial applications. Shielding lead, on the other hand, is dense and used for radiation protection in medical, nuclear, and industrial environments, effectively blocking harmful ionizing radiation. Both types of lead serve specialized functions, with battery lead focusing on electrochemical performance and shielding lead emphasizing safety through radiation attenuation.

Composition Differences Between Battery Lead and Shielding Lead

Battery lead primarily consists of lead-antimony or lead-calcium alloys to enhance mechanical strength and corrosion resistance, essential for battery grid durability and longevity. Shielding lead, used in radiation protection, is usually high-purity elemental lead or lead with minimal alloying elements to maximize density and attenuation properties. The key compositional difference lies in battery lead's alloy additions for structural integrity versus shielding lead's emphasis on purity for optimal radiation shielding performance.

Primary Uses: Batteries vs Radiation Protection

Battery lead is primarily used in the manufacture of lead-acid batteries, providing high conductivity and corrosion resistance essential for energy storage in automotive and industrial applications. Shielding lead is employed in radiation protection, utilizing its density and atomic number to effectively block X-rays and gamma rays in medical, nuclear, and research environments. The distinct physical and chemical properties of these types make battery lead optimal for electrical applications, while shielding lead is specialized for safety in radiation-heavy settings.

Physical Properties Comparison

Battery lead exhibits high density and excellent corrosion resistance, making it ideal for electrochemical applications in batteries. Shielding lead typically has a high atomic number and density, providing superior radiation attenuation and physical robustness for protective barriers. Both types share similar malleability and tensile strength, but differ primarily in surface treatment and purity to suit their specific functional requirements.

Manufacturing Processes for Battery Lead and Shielding Lead

Manufacturing battery lead involves casting or rolling pure lead or lead alloys into grids or plates designed to support active materials in lead-acid batteries, ensuring high electrical conductivity and corrosion resistance. Shielding lead is produced through processes such as rolling or extruding dense lead sheets or alloys to achieve uniform thickness and optimal density for effective radiation protection. Both battery and shielding lead require precise control of alloy composition and mechanical properties to meet their specific functional demands in energy storage and radiation shielding applications.

Purity and Alloying Elements in Battery vs Shielding Lead

Battery lead typically exhibits higher purity, often exceeding 99.97%, with minimal alloying elements to enhance electrical conductivity and corrosion resistance crucial for optimal battery performance. In contrast, shielding lead contains specific alloying elements such as antimony, tin, or calcium to improve mechanical strength and hardness, which are essential for effective radiation shielding. The controlled variations in purity and alloy composition directly influence the functional properties, distinguishing battery lead's electrochemical efficiency from shielding lead's durability and protective capabilities.

Environmental and Recycling Considerations

Battery lead, primarily used in lead-acid batteries, poses significant environmental challenges due to its high toxicity and potential for soil and water contamination if improperly disposed of. Shielding lead, commonly utilized for radiation protection, often contains additives to enhance durability, which complicates recycling processes and increases hazardous waste risks. Effective recycling of both types requires specialized facilities that can safely extract and repurpose lead while minimizing environmental impact and adhering to stringent regulatory standards.

Safety Concerns and Handling Requirements

Battery lead presents specific safety concerns due to its high toxicity and potential for lead dust contamination, requiring strict handling protocols such as using personal protective equipment and proper ventilation. Shielding lead, commonly used in radiation protection, demands careful handling to avoid lead exposure and environmental contamination, with emphasis on secure storage and disposal procedures. Both forms necessitate rigorous safety training and monitoring to minimize health risks and ensure regulatory compliance.

Cost Analysis: Battery Lead vs Shielding Lead

Battery lead typically incurs higher costs due to its higher purity requirements and specialized processing to ensure optimal electrochemical performance. Shielding lead is generally more cost-effective, benefiting from lower purity standards and simpler manufacturing processes used in radiation protection applications. Cost differences are influenced by raw material quality, production complexity, and end-use specifications, with battery lead demanding greater investment for superior conductivity and durability.

Future Trends and Innovations in Lead Materials

Future trends in lead materials emphasize the development of battery lead alloys with enhanced conductivity and corrosion resistance to improve electric vehicle battery efficiency and lifespan. Innovations in shielding lead focus on advanced composites that maintain radiation protection while reducing weight and toxicity, supporting safer and more sustainable medical and industrial applications. Research into nano-engineered lead materials aims to optimize performance characteristics, promoting eco-friendly recycling processes and regulatory compliance.

Battery lead vs Shielding lead Infographic

materialdif.com

materialdif.com