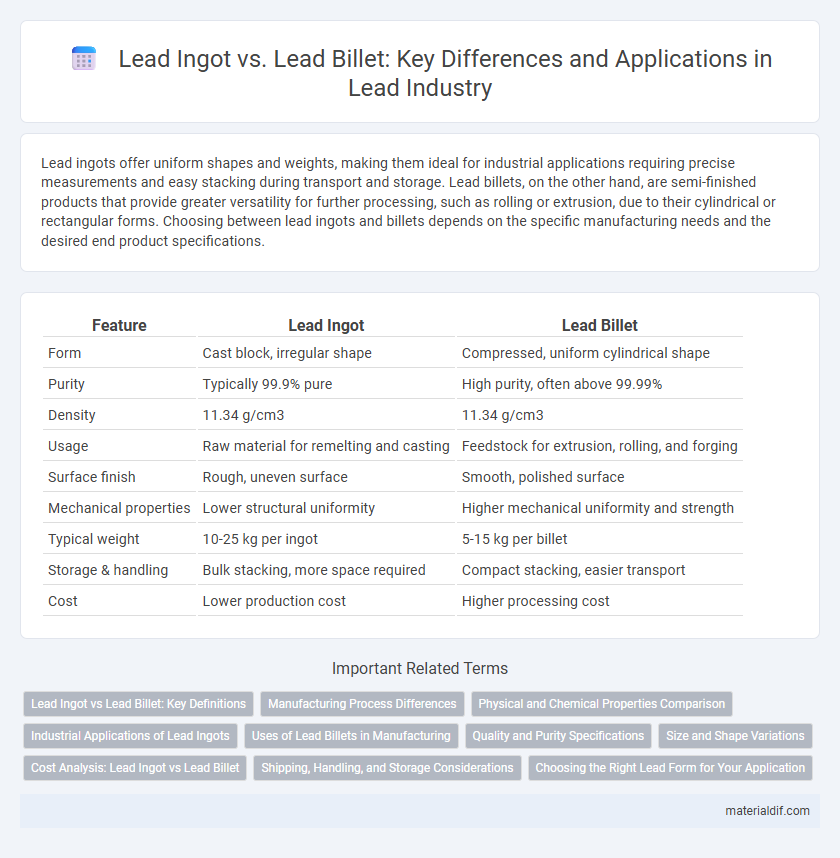

Lead ingots offer uniform shapes and weights, making them ideal for industrial applications requiring precise measurements and easy stacking during transport and storage. Lead billets, on the other hand, are semi-finished products that provide greater versatility for further processing, such as rolling or extrusion, due to their cylindrical or rectangular forms. Choosing between lead ingots and billets depends on the specific manufacturing needs and the desired end product specifications.

Table of Comparison

| Feature | Lead Ingot | Lead Billet |

|---|---|---|

| Form | Cast block, irregular shape | Compressed, uniform cylindrical shape |

| Purity | Typically 99.9% pure | High purity, often above 99.99% |

| Density | 11.34 g/cm3 | 11.34 g/cm3 |

| Usage | Raw material for remelting and casting | Feedstock for extrusion, rolling, and forging |

| Surface finish | Rough, uneven surface | Smooth, polished surface |

| Mechanical properties | Lower structural uniformity | Higher mechanical uniformity and strength |

| Typical weight | 10-25 kg per ingot | 5-15 kg per billet |

| Storage & handling | Bulk stacking, more space required | Compact stacking, easier transport |

| Cost | Lower production cost | Higher processing cost |

Lead Ingot vs Lead Billet: Key Definitions

Lead ingots and lead billets are both primary forms of refined lead used in manufacturing and industrial applications, but they differ in size, shape, and processing method. Lead ingots typically have a larger, flatter shape and are produced by casting molten lead into molds, making them suitable for remelting and further refining. Lead billets, on the other hand, are smaller, cylindrical pieces often created through extrusion or rolling processes, which provide improved mechanical properties for specific industrial uses.

Manufacturing Process Differences

Lead ingots are produced by casting molten lead into molds, allowing it to cool and solidify into large, standardized blocks. Lead billets undergo additional processing after casting, including extrusion or rolling, to form smaller, more uniform shapes suitable for further manufacturing. The key manufacturing difference lies in the billet's secondary shaping processes, which enhance dimensional precision and mechanical properties compared to ingots.

Physical and Chemical Properties Comparison

Lead ingots exhibit higher density and lower porosity compared to lead billets, resulting in enhanced mechanical stability and corrosion resistance. Chemically, both ingots and billets share similar purity levels of lead (Pb), generally exceeding 99.9%, but billets often contain minor alloying elements that slightly alter their melting point and hardness. The crystalline structure in ingots tends to be more uniform, whereas billets display a finer grain size due to their manufacturing process, impacting their ductility and machining characteristics.

Industrial Applications of Lead Ingots

Lead ingots, characterized by their uniform shape and high purity, are preferred in industrial applications such as battery manufacturing, radiation shielding, and cable sheathing due to their ease of melting and refining. Compared to lead billets, ingots offer greater consistency in composition and dimensions, ensuring efficient processing in casting and alloying operations. Their widespread use in producing lead-acid batteries highlights their critical role in energy storage technologies within the industrial sector.

Uses of Lead Billets in Manufacturing

Lead billets are primarily used in manufacturing for casting and forging processes due to their uniform composition and size, which allows for consistent melting and reshaping. These billets serve as raw materials for producing lead sheets, pipes, and various components in battery manufacturing and radiation shielding industries. Unlike lead ingots, billets offer better mechanical properties and precision, making them ideal for high-quality lead product fabrication.

Quality and Purity Specifications

Lead ingots typically boast higher quality and purity specifications than lead billets, often exceeding 99.97% pure lead content, making them ideal for applications demanding stringent material standards. The refining and casting processes for lead ingots ensure a denser, more uniform microstructure that minimizes impurities and enhances conductivity. Lead billets, while also produced with quality in mind, may have slightly lower purity levels and exhibit more internal grain boundaries, influencing their suitability for secondary processing and alloying.

Size and Shape Variations

Lead ingots typically feature a larger, rectangular block shape with standard dimensions ranging from 10 to 25 kilograms, designed for easy stacking and storage. Lead billets are smaller, often cylindrical or square cross-section bars, varying in length from 200 to 500 millimeters, which facilitates easier handling for further processing or manufacturing. The size and shape differences between lead ingots and billets directly influence their applications in industries such as battery manufacturing and metal casting.

Cost Analysis: Lead Ingot vs Lead Billet

Lead ingots typically incur lower production costs due to simpler casting processes and reduced machining requirements compared to lead billets. Lead billets demand higher manufacturing expenses because of additional forging and processing steps that improve material strength and uniformity. Cost analysis reveals lead ingots are more economical for bulk applications, while lead billets justify their premium price in precision and performance-sensitive uses.

Shipping, Handling, and Storage Considerations

Lead ingots offer a dense, compact form ideal for efficient stacking and transportation, minimizing space requirements during shipping. Lead billets, typically longer and cylindrical, require specialized handling equipment to prevent deformation and ensure safety during loading and unloading processes. Proper storage for both forms demands moisture-controlled environments to prevent oxidation and maintain metal integrity over extended periods.

Choosing the Right Lead Form for Your Application

Lead ingots offer a standardized mass ideal for melting and casting processes, featuring smooth surfaces that simplify handling and storage. Lead billets, characterized by their longer, cylindrical shape, provide better suitability for extrusion and forging operations requiring precise dimensional control. Selecting between ingot and billet depends on the manufacturing method and specific application requirements, including melting efficiency and mechanical processing needs.

Lead ingot vs Lead billet Infographic

materialdif.com

materialdif.com