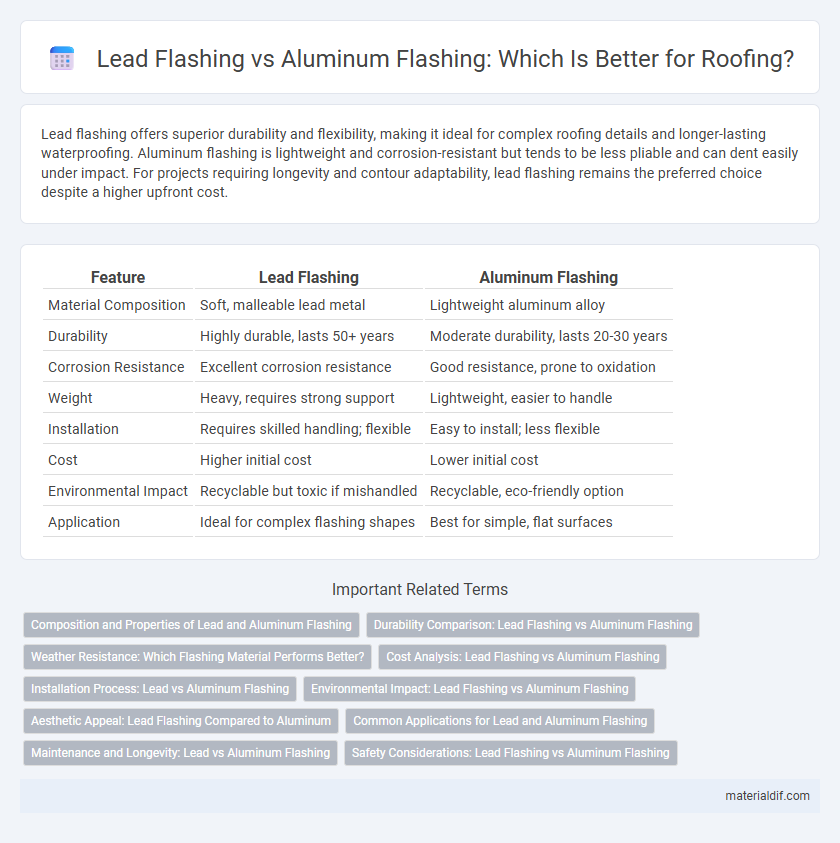

Lead flashing offers superior durability and flexibility, making it ideal for complex roofing details and longer-lasting waterproofing. Aluminum flashing is lightweight and corrosion-resistant but tends to be less pliable and can dent easily under impact. For projects requiring longevity and contour adaptability, lead flashing remains the preferred choice despite a higher upfront cost.

Table of Comparison

| Feature | Lead Flashing | Aluminum Flashing |

|---|---|---|

| Material Composition | Soft, malleable lead metal | Lightweight aluminum alloy |

| Durability | Highly durable, lasts 50+ years | Moderate durability, lasts 20-30 years |

| Corrosion Resistance | Excellent corrosion resistance | Good resistance, prone to oxidation |

| Weight | Heavy, requires strong support | Lightweight, easier to handle |

| Installation | Requires skilled handling; flexible | Easy to install; less flexible |

| Cost | Higher initial cost | Lower initial cost |

| Environmental Impact | Recyclable but toxic if mishandled | Recyclable, eco-friendly option |

| Application | Ideal for complex flashing shapes | Best for simple, flat surfaces |

Composition and Properties of Lead and Aluminum Flashing

Lead flashing is composed primarily of pure lead, known for its high malleability, corrosion resistance, and ability to conform to irregular surfaces, making it ideal for waterproofing in roofing applications. Aluminum flashing consists of lightweight aluminum alloy, offering excellent durability, resistance to rust, and a high strength-to-weight ratio, but with less flexibility compared to lead. The chemical inertness of lead ensures long-term protection against harsh weather, while aluminum flashing provides a cost-effective, sustainable solution with rapid installation benefits.

Durability Comparison: Lead Flashing vs Aluminum Flashing

Lead flashing offers superior durability due to its high malleability and resistance to corrosion, lasting upwards of 50 years in various weather conditions. Aluminum flashing, while lighter and more cost-effective, typically endures around 20-30 years before showing signs of wear such as oxidation and deformation. The longevity of lead flashing makes it a preferred choice for roofing applications requiring long-term protection against water ingress.

Weather Resistance: Which Flashing Material Performs Better?

Lead flashing offers superior weather resistance due to its malleability and ability to expand and contract with temperature changes without cracking. Aluminum flashing, while lightweight and corrosion-resistant, may become brittle over time, especially in extreme weather conditions. For long-term durability in harsh climates, lead flashing outperforms aluminum by maintaining a watertight seal and resisting freeze-thaw damage.

Cost Analysis: Lead Flashing vs Aluminum Flashing

Lead flashing typically costs between $15 to $30 per linear foot, making it more expensive than aluminum flashing, which ranges from $3 to $10 per linear foot. The higher initial investment in lead flashing is offset by its superior durability, often lasting over 50 years compared to aluminum's 20-30 year lifespan. Maintenance and replacement costs favor lead flashing due to its resistance to corrosion and weathering, potentially reducing long-term expenses despite the upfront price difference.

Installation Process: Lead vs Aluminum Flashing

Lead flashing installation involves heavy, malleable sheets that require careful bending and shaping around roof joints, offering excellent durability and weather resistance. Aluminum flashing installation is lighter and easier to handle, but it demands precise cutting and fastening to prevent corrosion and potential warping over time. Compared to aluminum, lead flashing typically requires more skill and time during installation but provides superior long-term performance in complex roof details.

Environmental Impact: Lead Flashing vs Aluminum Flashing

Lead flashing, known for its durability and malleability, poses significant environmental concerns due to its toxicity and potential to contaminate soil and water through runoff. Aluminum flashing offers a more eco-friendly alternative, being fully recyclable and less harmful to ecosystems while still providing effective weatherproofing. Choosing aluminum flashing reduces long-term environmental risks associated with lead pollution and supports sustainable building practices.

Aesthetic Appeal: Lead Flashing Compared to Aluminum

Lead flashing offers a traditional, matte gray finish that blends seamlessly with slate and tile roofing, enhancing the historical and architectural character of a building. Aluminum flashing, often brighter and more reflective, provides a modern look but may appear less natural on older structures. The natural patina that develops on lead over time adds to its aesthetic appeal, while aluminum may require painting to maintain a consistent appearance.

Common Applications for Lead and Aluminum Flashing

Lead flashing is commonly used in historic building restoration and high-end roofing projects due to its exceptional malleability and long lifespan, making it ideal for intricate chimneys, valleys, and roof joints. Aluminum flashing is favored in modern construction for residential and commercial roofing where lightweight, corrosion resistance, and cost-efficiency are priorities, often applied to edge trims, gutters, and wall joints. Both materials provide effective moisture barriers, but lead excels in complex architectural details while aluminum is preferred for straightforward, widespread flashing needs.

Maintenance and Longevity: Lead vs Aluminum Flashing

Lead flashing offers superior durability and requires minimal maintenance due to its natural resistance to corrosion and weathering, often lasting over 100 years without significant wear. Aluminum flashing, while more lightweight and cost-effective, generally has a shorter lifespan of around 20-30 years and may necessitate regular inspections and repairs to prevent oxidation and deformation. Choosing lead flashing enhances long-term structural protection with lower upkeep, whereas aluminum demands more frequent maintenance to ensure longevity.

Safety Considerations: Lead Flashing vs Aluminum Flashing

Lead flashing offers superior durability and corrosion resistance, making it highly effective in preventing water infiltration and ensuring long-term safety in roofing applications. Aluminum flashing, while lightweight and easier to install, may be prone to corrosion and damage in harsh environmental conditions, potentially compromising its protective function. Selecting lead flashing enhances structural integrity and reduces maintenance risks, whereas aluminum requires frequent inspections to maintain safety standards.

Lead flashing vs Aluminum flashing Infographic

materialdif.com

materialdif.com