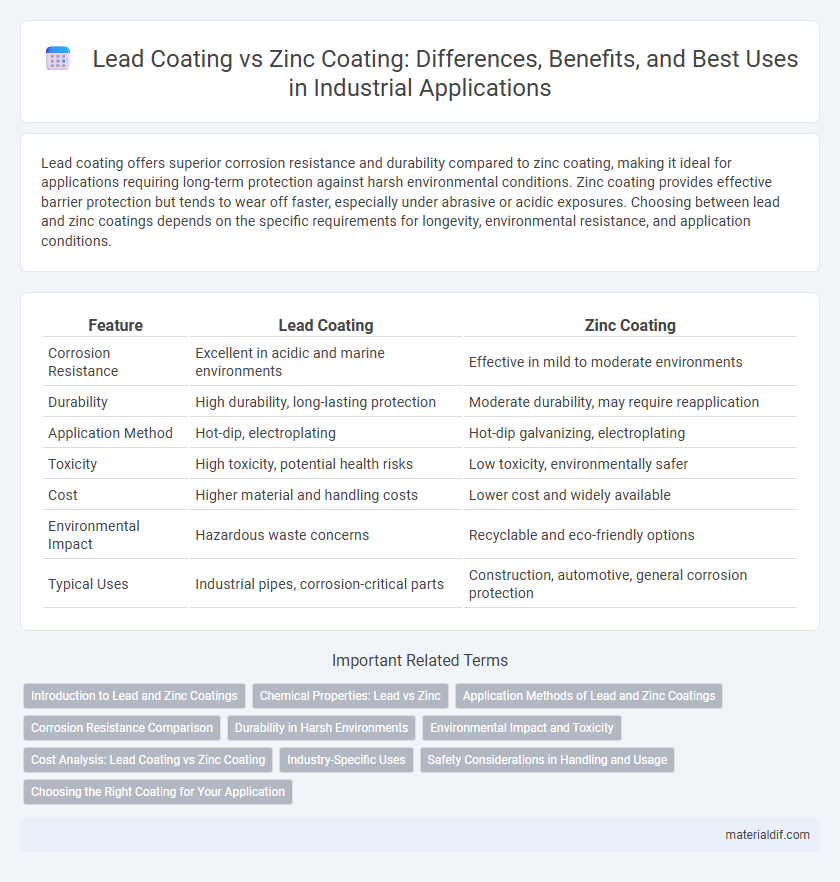

Lead coating offers superior corrosion resistance and durability compared to zinc coating, making it ideal for applications requiring long-term protection against harsh environmental conditions. Zinc coating provides effective barrier protection but tends to wear off faster, especially under abrasive or acidic exposures. Choosing between lead and zinc coatings depends on the specific requirements for longevity, environmental resistance, and application conditions.

Table of Comparison

| Feature | Lead Coating | Zinc Coating |

|---|---|---|

| Corrosion Resistance | Excellent in acidic and marine environments | Effective in mild to moderate environments |

| Durability | High durability, long-lasting protection | Moderate durability, may require reapplication |

| Application Method | Hot-dip, electroplating | Hot-dip galvanizing, electroplating |

| Toxicity | High toxicity, potential health risks | Low toxicity, environmentally safer |

| Cost | Higher material and handling costs | Lower cost and widely available |

| Environmental Impact | Hazardous waste concerns | Recyclable and eco-friendly options |

| Typical Uses | Industrial pipes, corrosion-critical parts | Construction, automotive, general corrosion protection |

Introduction to Lead and Zinc Coatings

Lead coatings provide excellent corrosion resistance and protect metal surfaces in harsh environments by forming a durable barrier against moisture and chemicals. Zinc coatings, applied through galvanization, offer sacrificial protection by corroding preferentially and preserving the underlying steel from rust. Both lead and zinc coatings serve critical roles in industrial applications, with lead favored for chemical resistance and zinc preferred for structural longevity and cost-effectiveness.

Chemical Properties: Lead vs Zinc

Lead exhibits excellent corrosion resistance due to the formation of a stable oxide layer that protects the metal beneath, while zinc primarily relies on sacrificial corrosion, acting as an anode to prevent steel oxidation. Chemically, lead has poor reactivity with acids and alkalis, whereas zinc reacts more readily, forming zinc salts and exhibiting amphoteric behavior. The denser atomic structure of lead provides superior barrier protection, contrasting with zinc's galvanic protection mechanism in coatings.

Application Methods of Lead and Zinc Coatings

Lead coatings are commonly applied through hot-dipping and electroplating, offering excellent corrosion resistance for pipes, roofing, and batteries. Zinc coatings typically utilize galvanizing methods such as hot-dip galvanizing or electrogalvanizing, providing durable protection for steel structures and automotive parts. Both methods ensure a protective barrier, but lead coatings excel in chemical environments while zinc coatings are preferred for preventing rust in outdoor applications.

Corrosion Resistance Comparison

Lead coating provides superior corrosion resistance compared to zinc coating due to its dense, impermeable nature that effectively blocks moisture and oxygen. Zinc coating offers sacrificial protection by oxidizing first, which slows down corrosion on the underlying metal but is less durable in highly corrosive environments. In marine or acidic conditions, lead coatings maintain integrity longer, whereas zinc coatings may degrade more quickly, necessitating frequent maintenance or replacement.

Durability in Harsh Environments

Lead coating offers superior durability in harsh environments due to its excellent corrosion resistance and ability to withstand acidic and marine conditions without significant degradation. Zinc coating provides sacrificial protection by corroding preferentially, but it may deteriorate faster in highly acidic or saline environments. For long-term protection in extreme conditions, lead coating remains a more robust option compared to zinc coating.

Environmental Impact and Toxicity

Lead coating poses significant environmental and health risks due to lead's high toxicity and persistence in ecosystems, leading to soil and water contamination and bioaccumulation in wildlife. Zinc coating offers a less toxic alternative, as zinc is an essential trace element with lower environmental persistence and reduced risks of poisoning, though excessive zinc can still impact aquatic life. Choosing zinc coating over lead helps minimize ecological damage and human health hazards associated with heavy metal exposure.

Cost Analysis: Lead Coating vs Zinc Coating

Lead coating generally incurs higher material and environmental compliance costs compared to zinc coating, which is more cost-effective due to abundant availability and lower toxicity. Zinc coating, commonly applied via galvanization, reduces maintenance expenses by providing longer-lasting corrosion protection, decreasing total lifecycle costs. Cost analysis reveals zinc coating as the preferred economical choice for large-scale industrial applications where budget constraints and environmental regulations are critical factors.

Industry-Specific Uses

Lead coating offers superior corrosion resistance and is predominantly used in plumbing, chemical storage, and battery manufacturing industries due to its durability against acidic and alkaline environments. Zinc coating, commonly known as galvanization, is widely applied in the construction and automotive sectors for protecting steel and iron from rust through sacrificial oxidation. Industry-specific requirements dictate the choice, with lead coating favored for heavy-duty chemical applications and zinc coating preferred for structural and outdoor metal protection.

Safety Considerations in Handling and Usage

Lead coating poses significant health risks due to lead's toxicity, requiring strict safety measures such as protective gloves and proper ventilation during handling to prevent lead poisoning. Zinc coating, often used as a safer alternative, is less hazardous but still necessitates precautions to avoid inhaling zinc oxide fumes generated during welding or heating processes. Workers should follow industry standards and regulatory guidelines to minimize exposure and ensure safe usage of both coatings in industrial applications.

Choosing the Right Coating for Your Application

Lead coating offers excellent corrosion resistance and durability for applications exposed to harsh environments, making it ideal for industrial uses requiring long-term protection. Zinc coating provides sacrificial protection through galvanization, effectively preventing rust on steel and iron surfaces, suitable for construction and outdoor projects. Selecting the right coating depends on factors such as environmental exposure, substrate material, and cost considerations to ensure optimal performance and longevity.

Lead Coating vs Zinc Coating Infographic

materialdif.com

materialdif.com