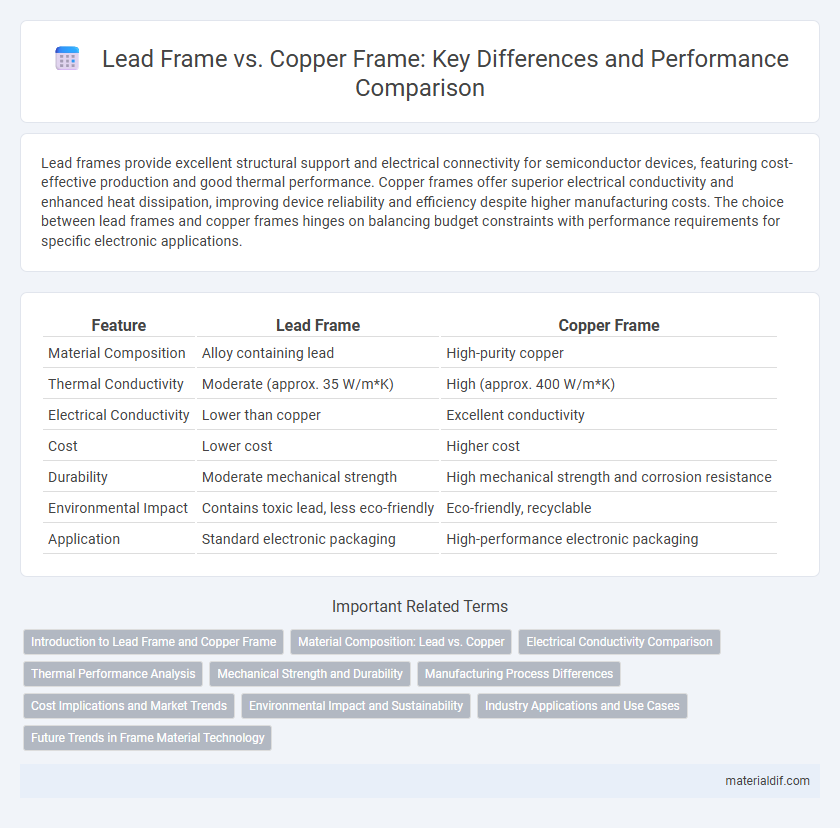

Lead frames provide excellent structural support and electrical connectivity for semiconductor devices, featuring cost-effective production and good thermal performance. Copper frames offer superior electrical conductivity and enhanced heat dissipation, improving device reliability and efficiency despite higher manufacturing costs. The choice between lead frames and copper frames hinges on balancing budget constraints with performance requirements for specific electronic applications.

Table of Comparison

| Feature | Lead Frame | Copper Frame |

|---|---|---|

| Material Composition | Alloy containing lead | High-purity copper |

| Thermal Conductivity | Moderate (approx. 35 W/m*K) | High (approx. 400 W/m*K) |

| Electrical Conductivity | Lower than copper | Excellent conductivity |

| Cost | Lower cost | Higher cost |

| Durability | Moderate mechanical strength | High mechanical strength and corrosion resistance |

| Environmental Impact | Contains toxic lead, less eco-friendly | Eco-friendly, recyclable |

| Application | Standard electronic packaging | High-performance electronic packaging |

Introduction to Lead Frame and Copper Frame

Lead frames serve as foundational mechanical supports and electrical interconnects in semiconductor device packaging, typically made from materials like copper alloys with plating to enhance conductivity and corrosion resistance. Copper frames, known for their superior thermal and electrical conductivity compared to traditional lead frames, are increasingly favored in high-performance semiconductor applications to improve heat dissipation and signal integrity. Understanding the material properties and functional roles of lead frames versus copper frames is essential for optimizing integrated circuit packaging and ensuring device reliability.

Material Composition: Lead vs. Copper

Lead frames consist primarily of lead alloys known for their excellent electrical conductivity and ease of molding, making them widely used in semiconductor packaging. Copper frames, composed predominantly of high-purity copper, offer superior thermal conductivity and mechanical strength, enhancing heat dissipation and reliability in electronic components. The choice between lead and copper frames hinges on balancing material properties, with copper frames preferred in high-performance applications due to their enhanced durability and thermal management capabilities.

Electrical Conductivity Comparison

Copper frames exhibit significantly higher electrical conductivity compared to lead frames, making them ideal for applications demanding efficient current flow and reduced resistance. While lead frames offer durability and cost-effectiveness, their lower conductivity results in increased power loss and heat generation under high electrical loads. The superior conductivity of copper frames ensures enhanced performance in semiconductor packaging and electronic device reliability.

Thermal Performance Analysis

Copper frames exhibit superior thermal conductivity compared to standard lead frames, enabling more efficient heat dissipation in semiconductor packages. This enhanced thermal performance reduces the junction temperature, improving device reliability and lifespan. Thermal analysis demonstrates copper frames maintain lower operating temperatures under high power conditions, making them preferable for advanced electronic applications.

Mechanical Strength and Durability

Copper frames exhibit superior mechanical strength and durability compared to lead frames due to copper's higher tensile strength and resistance to deformation under stress. Copper's excellent thermal conductivity also enhances the frame's ability to withstand thermal cycling without cracking or warping. Consequently, copper frames provide enhanced reliability and longevity in electronic packaging applications where mechanical robustness is critical.

Manufacturing Process Differences

Lead frames undergo a stamping process from thin metal sheets, typically using materials like copper or alloy, enabling precise, cost-effective mass production of semiconductor packages. Copper frames require additional plating and heat treatment steps to enhance thermal conductivity and mechanical strength, involving more complex processing compared to standard lead frames. The manufacturing of copper frames demands stricter control over oxidation and surface finishing to maintain conductivity and ensure package reliability during semiconductor assembly.

Cost Implications and Market Trends

Lead frames typically offer lower material costs compared to copper frames, making them a cost-effective choice for high-volume semiconductor packaging. Copper frames provide superior thermal conductivity and mechanical strength but come with higher raw material and processing expenses, influencing overall production budgets. Market trends show a gradual shift towards copper frames driven by demand for enhanced device performance despite the cost premium, particularly in high-reliability automotive and industrial applications.

Environmental Impact and Sustainability

Lead frames have been traditionally used in semiconductor packaging but pose significant environmental concerns due to lead's toxicity and challenges in disposal and recycling. Copper frames offer a more sustainable alternative with higher recyclability, reduced environmental toxicity, and improved thermal conductivity that enhances device longevity. Adoption of copper frames aligns with global regulatory trends aiming to minimize hazardous substances and promote eco-friendly manufacturing practices.

Industry Applications and Use Cases

Lead frames are widely used in semiconductor packaging due to their excellent electrical conductivity and compatibility with automated assembly processes, making them ideal for integrated circuits in consumer electronics and automotive applications. Copper frames offer superior thermal conductivity and mechanical strength, which enhances heat dissipation and structural integrity, critical in high-power devices and industrial equipment. Both lead and copper frames serve specific industry needs, with lead frames dominating cost-sensitive mass production and copper frames preferred in high-reliability, high-performance use cases.

Future Trends in Frame Material Technology

Lead frame technology, traditionally favored for its cost-effectiveness and reliability, faces increasing competition from copper frames due to copper's superior electrical conductivity and thermal performance. Emerging trends emphasize advanced copper alloy developments and surface treatments that enhance mechanical strength and corrosion resistance, promising significant improvements in semiconductor packaging efficiency. Future innovations will likely integrate nanoscale material engineering and environmentally sustainable processes to meet the demands of high-performance, miniaturized electronic devices.

Lead Frame vs Copper Frame Infographic

materialdif.com

materialdif.com