Lead battery plates provide exceptional conductivity and corrosion resistance, making them ideal for energy storage in automotive and industrial applications. Nickel plates offer superior durability and high-temperature tolerance, often used in rechargeable batteries requiring longer life cycles. Choosing between lead battery plates and nickel plates depends on the specific performance needs, cost considerations, and environmental impact of the application.

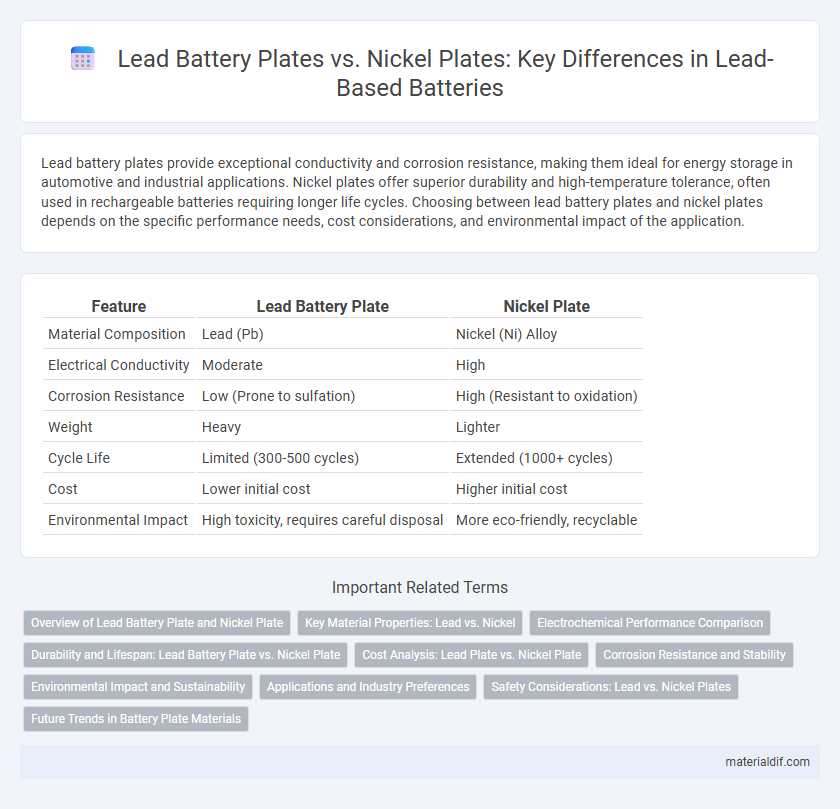

Table of Comparison

| Feature | Lead Battery Plate | Nickel Plate |

|---|---|---|

| Material Composition | Lead (Pb) | Nickel (Ni) Alloy |

| Electrical Conductivity | Moderate | High |

| Corrosion Resistance | Low (Prone to sulfation) | High (Resistant to oxidation) |

| Weight | Heavy | Lighter |

| Cycle Life | Limited (300-500 cycles) | Extended (1000+ cycles) |

| Cost | Lower initial cost | Higher initial cost |

| Environmental Impact | High toxicity, requires careful disposal | More eco-friendly, recyclable |

Overview of Lead Battery Plate and Nickel Plate

Lead battery plates consist of a grid structure made from lead or lead alloys, designed to support active materials and facilitate electrochemical reactions in lead-acid batteries. Nickel plates, primarily used in nickel-cadmium or nickel-metal hydride batteries, feature a more corrosion-resistant substrate with a porous surface that enhances charge transfer and durability. The choice between lead battery plates and nickel plates depends on factors like conductivity, corrosion resistance, energy density, and battery application requirements.

Key Material Properties: Lead vs. Nickel

Lead battery plates exhibit excellent corrosion resistance and high electrical conductivity essential for efficient energy storage, while nickel plates offer superior mechanical strength and enhanced resistance to oxidation. The density of lead (11.34 g/cm3) contributes to higher energy density in batteries, whereas nickel's lower density (8.90 g/cm3) favors lighter, more durable applications. Thermal stability of nickel plates surpasses that of lead, making nickel a preferred choice in high-temperature environments despite lead's cost-effectiveness and recyclability.

Electrochemical Performance Comparison

Lead battery plates exhibit superior electrochemical performance characterized by high energy density and excellent charge retention, making them ideal for automotive and stationary energy storage applications. Nickel plates, while offering better corrosion resistance and longer cycle life, generally present lower conductivity and energy efficiency compared to lead plates. The electrochemical stability of lead plates under high discharge rates outperforms nickel plates, contributing to their widespread usage in lead-acid battery technologies.

Durability and Lifespan: Lead Battery Plate vs. Nickel Plate

Lead battery plates exhibit superior durability and a longer lifespan compared to nickel plates due to their high corrosion resistance and stable electrochemical properties. Nickel plates tend to degrade faster under continuous charge-discharge cycles, limiting their overall service life. The enhanced structural integrity of lead plates ensures consistent performance in lead-acid batteries over extended periods.

Cost Analysis: Lead Plate vs. Nickel Plate

Lead battery plates offer a significantly lower upfront cost compared to nickel plates, making them more economically viable for large-scale battery production. The price of lead as a raw material is approximately $2,000 per metric ton, whereas nickel costs around $18,000 per metric ton, which drives the higher expense in nickel plating. Maintenance and lifecycle costs also favor lead plates due to their proven durability and easier recyclability, contributing to overall cost efficiency in lead-based battery systems.

Corrosion Resistance and Stability

Lead battery plates exhibit superior corrosion resistance due to their lead dioxide and lead compositions, which offer enhanced chemical stability in acidic environments typical of lead-acid batteries. Nickel plates, while providing good mechanical strength and conductivity, tend to corrode faster in acidic electrolytes, reducing long-term stability. The inherent stability of lead plates ensures prolonged battery life and consistent performance under cyclic charging and discharging conditions, making them preferable for lead-acid battery applications.

Environmental Impact and Sustainability

Lead battery plates contribute significantly to environmental pollution due to lead's toxicity and challenges in recycling, causing soil and water contamination risks. In contrast, nickel plates used in batteries offer improved sustainability with higher corrosion resistance and longer lifespan, reducing the frequency of replacements and resource consumption. Despite nickel's higher initial environmental footprint, effective recycling programs make nickel plates a more sustainable choice compared to lead in battery applications.

Applications and Industry Preferences

Lead battery plates dominate the automotive and renewable energy sectors due to their high conductivity and cost-effectiveness, making them the preferred choice in lead-acid batteries for starters and energy storage systems. Nickel plates are favored in aerospace and marine industries for their superior corrosion resistance and durability under extreme conditions, ensuring longer lifespan and reliability. Industry preferences hinge on application demands, with lead plates balancing affordability and performance, while nickel plates cater to high-performance, corrosive environments.

Safety Considerations: Lead vs. Nickel Plates

Lead battery plates pose safety concerns due to their toxicity and potential for lead exposure, requiring careful handling and disposal to prevent environmental contamination. Nickel plates offer enhanced corrosion resistance and lower toxicity, reducing health risks during manufacturing and recycling processes. However, nickel's higher cost and potential allergenic effects must be managed in applications prioritizing safety.

Future Trends in Battery Plate Materials

The future trends in battery plate materials highlight a shift towards nickel plates due to their superior corrosion resistance, higher energy density, and improved cycle life compared to traditional lead battery plates. Advances in nickel plating technology enable enhanced conductivity and mechanical strength, making them ideal for next-generation batteries in electric vehicles and renewable energy storage systems. Research continues to focus on optimizing nickel alloy compositions and surface treatments to further boost performance, sustainability, and cost-effectiveness in battery manufacturing.

Lead Battery Plate vs Nickel Plate Infographic

materialdif.com

materialdif.com