Lead glazing provides a smooth, glossy finish and enhances color vibrancy but raises concerns due to lead toxicity, making it less safe for foodware. Borosilicate glazing, known for its durability and thermal resistance, offers a non-toxic alternative that withstands high temperatures without compromising the ceramic's integrity. Choosing borosilicate glazing ensures safer use and longevity, especially in kitchenware exposed to rapid temperature changes.

Table of Comparison

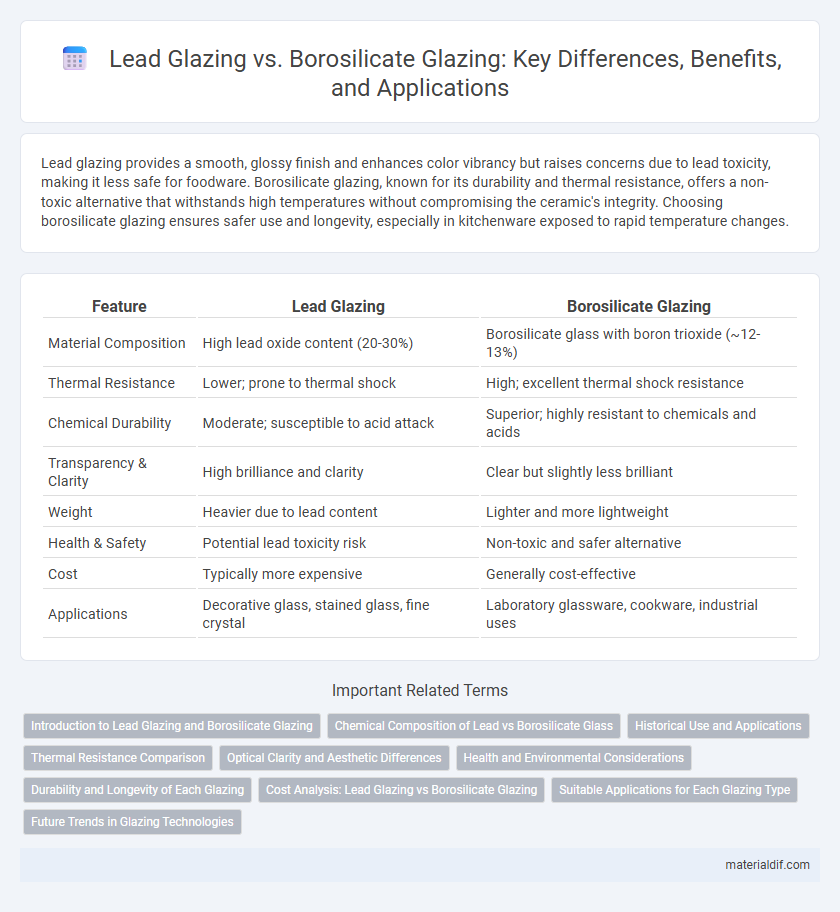

| Feature | Lead Glazing | Borosilicate Glazing |

|---|---|---|

| Material Composition | High lead oxide content (20-30%) | Borosilicate glass with boron trioxide (~12-13%) |

| Thermal Resistance | Lower; prone to thermal shock | High; excellent thermal shock resistance |

| Chemical Durability | Moderate; susceptible to acid attack | Superior; highly resistant to chemicals and acids |

| Transparency & Clarity | High brilliance and clarity | Clear but slightly less brilliant |

| Weight | Heavier due to lead content | Lighter and more lightweight |

| Health & Safety | Potential lead toxicity risk | Non-toxic and safer alternative |

| Cost | Typically more expensive | Generally cost-effective |

| Applications | Decorative glass, stained glass, fine crystal | Laboratory glassware, cookware, industrial uses |

Introduction to Lead Glazing and Borosilicate Glazing

Lead glazing involves applying a lead-based compound to ceramics, enhancing the surface's glossiness and providing a low melting point finish that fuses effectively with clay bodies. Borosilicate glazing uses borosilicate glass, known for its thermal resistance and durability, making it ideal for scientific and kitchenware applications. Both glazing techniques offer distinct advantages; lead glazing emphasizes aesthetic appeal and ease of melting, while borosilicate glazing prioritizes thermal stability and chemical resistance.

Chemical Composition of Lead vs Borosilicate Glass

Lead glazing primarily contains lead oxide (PbO), which enhances the glass's refractive index and density, making it highly reflective and suitable for decorative purposes. Borosilicate glass is composed mainly of silica (SiO2) and boron trioxide (B2O3), providing superior thermal resistance and chemical durability compared to lead glass. The differing chemical compositions result in distinct physical properties, with lead glaze being softer and more prone to corrosion, while borosilicate glazing offers enhanced resistance to thermal shock and chemical attack.

Historical Use and Applications

Lead glazing has been historically prized for its ability to produce vibrant, richly colored stained glass windows prominent in Gothic cathedrals and medieval architecture, due to its low melting point and ease of manipulation. Borosilicate glazing, developed in the 19th century, offers superior thermal resistance and chemical durability, making it ideal for scientific glassware, laboratory equipment, and high-temperature applications. While lead glazing dominates traditional and artistic contexts, borosilicate glazing is preferred in modern technical and industrial settings where strength and thermal shock resistance are critical.

Thermal Resistance Comparison

Lead glazing offers moderate thermal resistance, suitable for standard temperature ranges but prone to degradation under rapid thermal changes. Borosilicate glazing excels with high thermal resistance, enduring temperatures up to 450degC and showcasing superior resistance to thermal shock and expansion. This makes borosilicate glazing ideal for applications requiring durability under extreme heat and quick temperature fluctuations.

Optical Clarity and Aesthetic Differences

Lead glazing offers superior optical clarity due to its higher refractive index, producing a brilliant, sparkling finish favored in decorative applications. Borosilicate glazing provides enhanced durability and thermal resistance but results in a subtler, less vibrant appearance compared to lead glazing. This aesthetic difference makes lead glazing ideal for luxury glassware, while borosilicate excels in functional and scientific glass products.

Health and Environmental Considerations

Lead glazing contains toxic lead compounds that can leach into food or the environment, posing serious health risks such as lead poisoning and neurological damage. Borosilicate glazing is a safer alternative, offering high thermal shock resistance without releasing harmful substances or heavy metals. Environmental impact is minimized with borosilicate glazing due to its inert nature and lower toxicity during manufacturing and disposal.

Durability and Longevity of Each Glazing

Lead glazing demonstrates moderate durability with good weather resistance but tends to degrade faster under exposure to acidic environments and temperature fluctuations. Borosilicate glazing offers superior longevity, known for its exceptional thermal shock resistance and chemical inertness, enabling it to maintain structural integrity over extended periods. The enhanced durability of borosilicate makes it preferable for applications requiring long-term stability and resistance to harsh conditions.

Cost Analysis: Lead Glazing vs Borosilicate Glazing

Lead glazing generally incurs higher costs due to the material's toxicity and the need for specialized handling and disposal procedures, increasing labor and compliance expenses. Borosilicate glazing is more cost-effective owing to its durability, thermal resistance, and lower regulatory burdens, resulting in reduced maintenance and replacement costs over time. When evaluating total ownership expenses, borosilicate glazing offers a more economical solution compared to lead glazing despite lead's traditional advantages in specific optical properties.

Suitable Applications for Each Glazing Type

Lead glazing is ideal for decorative stained glass windows, art pieces, and traditional architectural restoration due to its excellent malleability and ease of soldering. Borosilicate glazing suits high-temperature laboratory glassware, chemical processing equipment, and industrial applications requiring thermal shock resistance and chemical durability. Each glazing type excels in environments aligned with their physical properties: lead glazing for aesthetic and low-heat uses, borosilicate for technical and high-heat scenarios.

Future Trends in Glazing Technologies

Future trends in glazing technologies emphasize sustainability and enhanced durability, with borosilicate glazing gaining traction due to its superior thermal resistance and chemical stability compared to traditional lead glazing. Innovations in nano-coatings and hybrid glazing systems aim to improve energy efficiency and environmental safety, reducing reliance on hazardous lead-based materials. The shift toward eco-friendly glazing solutions reflects increasing regulatory pressures and consumer demand for safer, high-performance glass products.

Lead Glazing vs Borosilicate Glazing Infographic

materialdif.com

materialdif.com