Lead anchors provide superior strength and durability compared to plastic anchors, making them ideal for heavy-duty applications and securing objects in masonry or concrete. Unlike plastic anchors, lead anchors offer better resistance to corrosion and deformation under stress, ensuring long-lasting stability. Their excellent load-bearing capacity makes lead anchors the preferred choice for critical structural fixings and heavy loads.

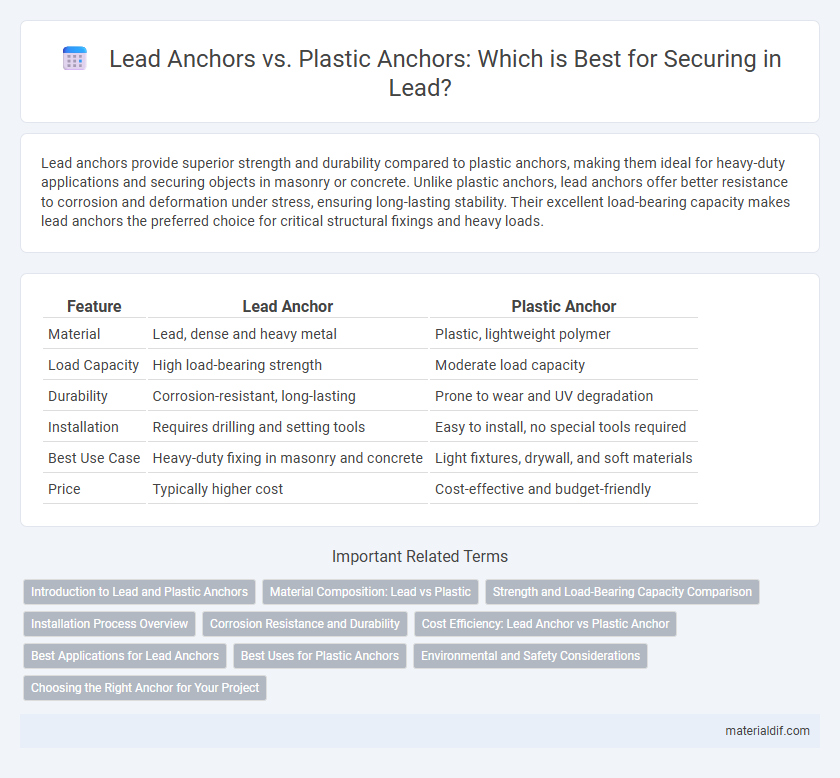

Table of Comparison

| Feature | Lead Anchor | Plastic Anchor |

|---|---|---|

| Material | Lead, dense and heavy metal | Plastic, lightweight polymer |

| Load Capacity | High load-bearing strength | Moderate load capacity |

| Durability | Corrosion-resistant, long-lasting | Prone to wear and UV degradation |

| Installation | Requires drilling and setting tools | Easy to install, no special tools required |

| Best Use Case | Heavy-duty fixing in masonry and concrete | Light fixtures, drywall, and soft materials |

| Price | Typically higher cost | Cost-effective and budget-friendly |

Introduction to Lead and Plastic Anchors

Lead anchors offer robust load-bearing capacity and excellent corrosion resistance, making them ideal for heavy-duty construction applications. Plastic anchors provide versatility and ease of installation, suited for light to medium loads and non-structural uses. Understanding the material properties, installation methods, and load capabilities is crucial when choosing between lead and plastic anchors.

Material Composition: Lead vs Plastic

Lead anchors are primarily composed of dense, malleable lead, which provides superior load-bearing capacity and excellent resistance to corrosion in various environments. Plastic anchors are made from durable polymers such as nylon or polyethylene, offering lightweight, corrosion-resistant alternatives that are ideal for medium to light-duty applications. The choice between lead and plastic anchors depends on specific structural requirements, environmental exposure, and the mechanical properties needed for secure fastening.

Strength and Load-Bearing Capacity Comparison

Lead anchors exhibit superior strength and enhanced load-bearing capacity compared to plastic anchors, making them ideal for heavy-duty applications in construction and masonry. Their dense composition allows for greater resistance under tensile and shear forces, ensuring stability in structural installations. Plastic anchors offer moderate support but typically underperform in high-load scenarios due to lower material rigidity and deformability under stress.

Installation Process Overview

Lead anchors require pre-drilling a hole followed by insertion and secure tightening, offering high load-bearing capacity ideal for heavy-duty applications. Plastic anchors also involve drilling a pilot hole, but they expand upon screw insertion, providing a lightweight and corrosion-resistant option suited for medium-duty tasks. The installation of lead anchors demands careful handling due to their weight and potential toxicity, whereas plastic anchors are easier and safer to install without specialized equipment.

Corrosion Resistance and Durability

Lead anchors offer superior corrosion resistance compared to plastic anchors due to their inherent metal composition, which withstands harsh environmental conditions without degrading. Plastic anchors, while resistant to corrosion by nature, often lack the long-term durability of lead, especially under heavy load or mechanical stress. The density and weight of lead anchors provide enhanced stability and durability, making them ideal for applications requiring long-lasting secure fixtures.

Cost Efficiency: Lead Anchor vs Plastic Anchor

Lead anchors offer superior load-bearing capacity and durability, making them cost-efficient for heavy-duty applications despite a higher initial price compared to plastic anchors. Plastic anchors provide a budget-friendly option ideal for light-duty tasks but may require frequent replacement, increasing long-term costs. Selecting lead anchors reduces maintenance expenses and ensures reliable performance, optimizing overall project cost efficiency.

Best Applications for Lead Anchors

Lead anchors provide superior corrosion resistance and excellent adaptability in diverse substrates like masonry and concrete, making them ideal for outdoor and marine environments. Their malleability ensures a tight fit, enhancing load-bearing capacity for heavy-duty applications such as structural supports and heavy machinery mounting. Compared to plastic anchors, lead anchors perform best in high-stress conditions requiring durability and long-term stability.

Best Uses for Plastic Anchors

Plastic anchors excel in securing lightweight fixtures to drywall, plaster, or masonry, making them ideal for hanging pictures, shelves, and light mirrors. Their resistance to corrosion and ease of installation suit indoor applications where metal anchors may rust or cause damage. Plastic anchors are best used in environments with minimal load requirements, providing a cost-effective and reliable solution for everyday household mounting tasks.

Environmental and Safety Considerations

Lead anchors pose significant environmental risks due to lead's toxicity and potential soil and water contamination, necessitating strict disposal and handling protocols. Plastic anchors offer improved safety and environmental profiles, being non-toxic and often recyclable, reducing ecological footprint during and after use. Selecting plastic anchors mitigates health hazards for workers and minimizes long-term environmental impact compared to lead alternatives.

Choosing the Right Anchor for Your Project

Choosing the right anchor depends on project requirements such as load capacity, durability, and environmental conditions. Lead anchors offer superior corrosion resistance and excellent load-bearing strength, ideal for heavy-duty and marine applications. Plastic anchors provide cost-effective, lightweight solutions suitable for light to medium loads in dry, indoor environments.

Lead Anchor vs Plastic Anchor Infographic

materialdif.com

materialdif.com