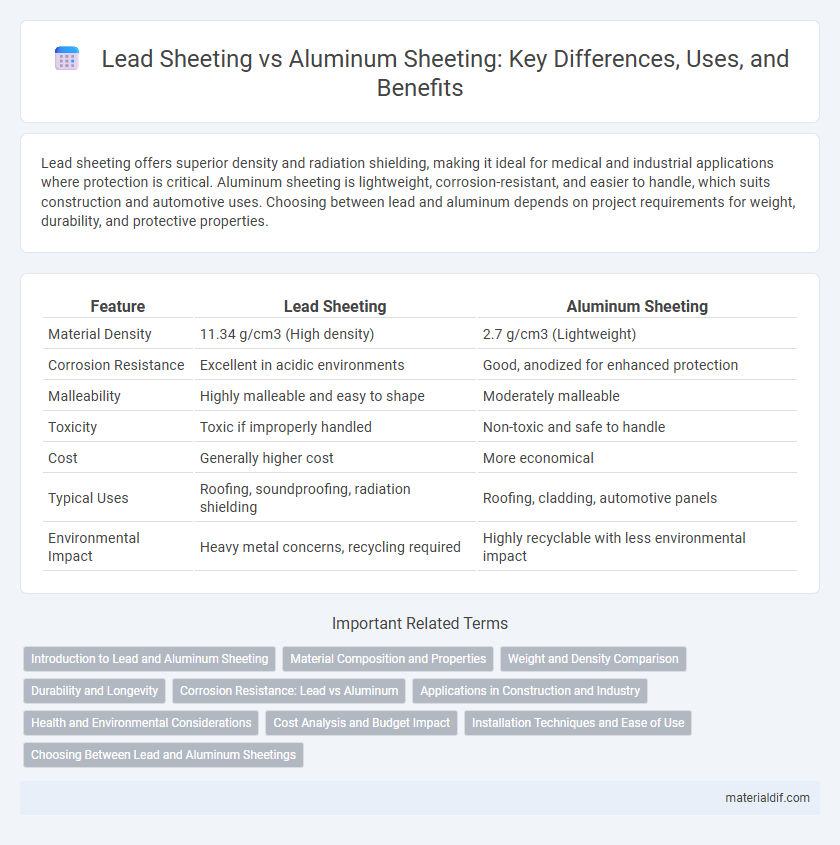

Lead sheeting offers superior density and radiation shielding, making it ideal for medical and industrial applications where protection is critical. Aluminum sheeting is lightweight, corrosion-resistant, and easier to handle, which suits construction and automotive uses. Choosing between lead and aluminum depends on project requirements for weight, durability, and protective properties.

Table of Comparison

| Feature | Lead Sheeting | Aluminum Sheeting |

|---|---|---|

| Material Density | 11.34 g/cm3 (High density) | 2.7 g/cm3 (Lightweight) |

| Corrosion Resistance | Excellent in acidic environments | Good, anodized for enhanced protection |

| Malleability | Highly malleable and easy to shape | Moderately malleable |

| Toxicity | Toxic if improperly handled | Non-toxic and safe to handle |

| Cost | Generally higher cost | More economical |

| Typical Uses | Roofing, soundproofing, radiation shielding | Roofing, cladding, automotive panels |

| Environmental Impact | Heavy metal concerns, recycling required | Highly recyclable with less environmental impact |

Introduction to Lead and Aluminum Sheeting

Lead sheeting offers superior density and radiation shielding, commonly used in roofing, flashing, and soundproofing applications due to its malleability and corrosion resistance. Aluminum sheeting provides lightweight durability with excellent corrosion resistance and thermal conductivity, ideal for automotive, aerospace, and construction industries. Choosing between lead and aluminum sheeting depends on factors like weight, environmental impact, and specific performance requirements.

Material Composition and Properties

Lead sheeting consists primarily of pure lead, known for its high density, malleability, and excellent corrosion resistance, making it ideal for waterproofing and radiation shielding applications. Aluminum sheeting, composed mainly of aluminum alloy, offers significantly lower weight, higher tensile strength, and enhanced resistance to oxidation, ensuring durability in structural and architectural uses. The choice between lead and aluminum sheeting depends heavily on the required material properties such as weight, strength, corrosion resistance, and specific environmental factors.

Weight and Density Comparison

Lead sheeting has a significantly higher density, approximately 11.34 g/cm3, compared to aluminum sheeting, which has a density around 2.70 g/cm3. This substantial difference in density makes lead sheets much heavier than aluminum sheets of the same size and thickness. The heavier weight of lead sheeting provides enhanced radiation shielding and soundproofing benefits but limits its use where lightweight materials are critical.

Durability and Longevity

Lead sheeting offers superior durability with exceptional resistance to corrosion, maintaining structural integrity in harsh environments for over 100 years. In comparison, aluminum sheeting, while lightweight and corrosion-resistant, typically has a shorter lifespan of 40-60 years due to susceptibility to oxidation and wear. The inherent density and malleability of lead provide enhanced weatherproofing and longevity ideal for roofing and waterproof flashing applications.

Corrosion Resistance: Lead vs Aluminum

Lead sheeting offers superior corrosion resistance compared to aluminum sheeting due to its inherent inertness and ability to form a protective oxide layer that prevents further oxidation. Aluminum sheeting, while also corrosion-resistant, is more susceptible to pitting and galvanic corrosion in certain environments, especially when exposed to saltwater or acidic conditions. The dense molecular structure of lead ensures long-term durability in harsh atmospheric or chemical exposures, making it the preferred choice for applications requiring extensive corrosion protection.

Applications in Construction and Industry

Lead sheeting offers superior durability and corrosion resistance, making it ideal for roofing, flashing, and waterproofing in construction. Aluminum sheeting provides lightweight strength and excellent thermal conductivity, often used in cladding, HVAC systems, and industrial frameworks. Both materials serve distinct purposes: lead excels in longevity and protection, while aluminum supports structural efficiency and ease of installation.

Health and Environmental Considerations

Lead sheeting poses significant health risks due to lead's toxicity, causing neurological damage and requiring strict handling precautions, while aluminum sheeting is non-toxic and safer for both workers and the environment. Environmentally, lead sheeting contributes to soil and water contamination through corrosion and disposal, whereas aluminum is highly recyclable and has a lower environmental impact throughout its lifecycle. Choosing aluminum sheeting supports healthier work environments and reduces long-term ecological hazards associated with lead.

Cost Analysis and Budget Impact

Lead sheeting typically incurs higher upfront material and installation costs compared to aluminum sheeting due to its density and specialized handling requirements. Aluminum sheeting offers a cost-effective alternative with lower material and labor expenses, while also providing longer lifespan and reduced maintenance, which positively impacts long-term budget planning. Evaluating the total cost of ownership, including durability and environmental factors, is crucial for making an informed decision between lead and aluminum sheeting.

Installation Techniques and Ease of Use

Lead sheeting installation involves techniques such as overlapping and welding to ensure weatherproof joints, requiring skilled labor due to its malleability and weight. Aluminum sheeting offers lighter weight and easier handling, allowing for faster installation with mechanical fasteners like screws or rivets, minimizing the need for specialized craftsmanship. The ease of use of aluminum sheeting makes it favorable for projects with tight schedules, while lead sheeting remains preferred for its durability in complex flashing and roofing details.

Choosing Between Lead and Aluminum Sheetings

Lead sheeting offers superior corrosion resistance and high density, making it ideal for roofing and waterproofing applications where durability and protection against environmental elements are critical. Aluminum sheeting is lightweight, highly malleable, and resistant to oxidation, which suits projects requiring ease of installation and long-term maintenance with minimal weight load. Choosing between lead and aluminum sheeting depends on balancing factors such as structural weight limits, environmental exposure, regulatory restrictions, and specific performance requirements in construction or manufacturing contexts.

Lead Sheeting vs Aluminum Sheeting Infographic

materialdif.com

materialdif.com