Lead foil offers superior radiation shielding compared to aluminum foil, making it essential for medical and industrial applications involving X-rays or gamma rays. While aluminum foil is lightweight, cost-effective, and commonly used for food storage, it lacks the density required to block harmful radiation effectively. Choosing lead foil ensures enhanced protection in environments where exposure to ionizing radiation is a concern.

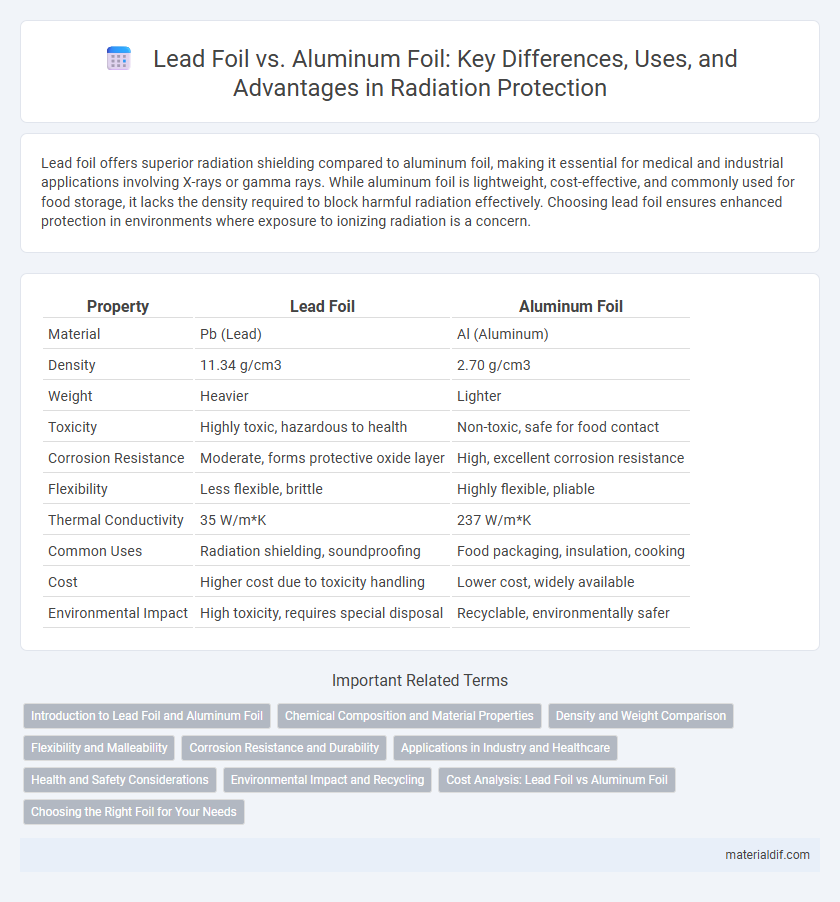

Table of Comparison

| Property | Lead Foil | Aluminum Foil |

|---|---|---|

| Material | Pb (Lead) | Al (Aluminum) |

| Density | 11.34 g/cm3 | 2.70 g/cm3 |

| Weight | Heavier | Lighter |

| Toxicity | Highly toxic, hazardous to health | Non-toxic, safe for food contact |

| Corrosion Resistance | Moderate, forms protective oxide layer | High, excellent corrosion resistance |

| Flexibility | Less flexible, brittle | Highly flexible, pliable |

| Thermal Conductivity | 35 W/m*K | 237 W/m*K |

| Common Uses | Radiation shielding, soundproofing | Food packaging, insulation, cooking |

| Cost | Higher cost due to toxicity handling | Lower cost, widely available |

| Environmental Impact | High toxicity, requires special disposal | Recyclable, environmentally safer |

Introduction to Lead Foil and Aluminum Foil

Lead foil is a dense, malleable metal sheet primarily used for radiation shielding and industrial applications due to its high atomic number and radiation absorption properties. Aluminum foil, in contrast, is a lightweight, corrosion-resistant metal commonly used for food packaging, insulation, and household purposes, valued for its excellent thermal conductivity and flexibility. Both foils serve distinct functions based on their physical and chemical properties, with lead foil excelling in protective roles and aluminum foil favored for everyday convenience.

Chemical Composition and Material Properties

Lead foil is primarily composed of elemental lead (Pb), a dense, malleable metal with a high atomic number that offers excellent radiation shielding and corrosion resistance, but it is toxic and has a low melting point of 327.5degC. Aluminum foil consists mainly of pure aluminum (Al), characterized by its lightweight, high tensile strength, excellent thermal and electrical conductivity, and a higher melting point of about 660.3degC, making it suitable for food packaging and insulation. The chemical inertness of aluminum contrasts with lead's toxicity, positioning aluminum foil as safe for consumer use while lead foil is often employed in industrial and medical applications where its density and shielding properties are critical.

Density and Weight Comparison

Lead foil has a significantly higher density, approximately 11.34 g/cm3, compared to aluminum foil's density of about 2.70 g/cm3, making lead foil much heavier for the same volume. This density difference results in lead foil being nearly four times heavier than aluminum foil of equivalent thickness and size. The substantial weight disparity influences applications where material weight and density are critical factors, such as in radiation shielding versus food packaging.

Flexibility and Malleability

Lead foil exhibits superior flexibility and malleability compared to aluminum foil, allowing it to be easily shaped and bent without cracking. Its dense atomic structure contributes to its ability to withstand repeated deformation while maintaining form. Aluminum foil, although flexible, tends to tear more easily under stress and lacks the same level of ductility as lead foil.

Corrosion Resistance and Durability

Lead foil offers superior corrosion resistance compared to aluminum foil due to its dense atomic structure and resistance to oxidation in acidic and alkaline environments. While aluminum foil is more prone to corrosion and degradation over time when exposed to moisture and chemicals, lead foil maintains its durability and integrity in harsh conditions. This makes lead foil an ideal choice for applications requiring long-term protection against environmental factors and chemical exposure.

Applications in Industry and Healthcare

Lead foil, known for its high density and radiation-shielding properties, is primarily used in medical and industrial radiology to protect against X-rays and gamma rays, ensuring safety in diagnostic imaging and nuclear facilities. Aluminum foil, valued for its lightweight, corrosion resistance, and thermal conductivity, is widely applied in food packaging, insulation, and pharmaceutical industries for barrier protection and heat sealing. While lead foil excels in radiation protection due to its atomic number and thickness, aluminum foil is preferred in sectors requiring flexibility, hygiene, and recyclability.

Health and Safety Considerations

Lead foil poses significant health risks due to lead's toxicity, which can cause neurological damage and other serious health issues upon prolonged exposure. Aluminum foil is generally considered safe for food use, although care should be taken to avoid ingestion of aluminum particles. Proper handling and disposal of lead foil are essential to prevent contamination and exposure in both industrial and household settings.

Environmental Impact and Recycling

Lead foil poses significant environmental hazards due to lead's toxicity and bioaccumulation risks, making it difficult to recycle safely without specialized processes. Aluminum foil, by contrast, is widely recyclable and has a lower environmental footprint when properly processed, as it can be reused indefinitely without loss of quality. Recycling aluminum foil conserves energy and reduces greenhouse gas emissions, whereas lead foil recycling requires strict regulatory controls to prevent soil and water contamination.

Cost Analysis: Lead Foil vs Aluminum Foil

Lead foil typically costs more than aluminum foil due to the higher raw material price and complex manufacturing processes involved in lead production. Aluminum foil is more cost-effective for widespread applications, benefiting from abundant availability and lower energy consumption during production. When analyzing long-term expenses, aluminum foil provides greater economic efficiency compared to lead foil, especially in large-scale industrial and consumer uses.

Choosing the Right Foil for Your Needs

Lead foil offers superior radiation shielding and heavy metal resistance, making it ideal for medical and industrial applications requiring high durability and protection. Aluminum foil provides excellent heat conductivity and is lightweight, suitable for everyday use like food storage and cooking. Selecting the right foil depends on specific needs such as radiation protection, thermal performance, and environmental safety considerations.

Lead Foil vs Aluminum Foil Infographic

materialdif.com

materialdif.com