Lead ballast provides superior weight and energy absorption compared to steel ballast, enhancing stability and reducing vibrations in marine and automotive applications. Its higher density allows for a smaller volume, making it ideal where space constraints exist. Steel ballast, while more affordable and corrosion-resistant, often requires larger quantities to achieve the same stability effect as lead.

Table of Comparison

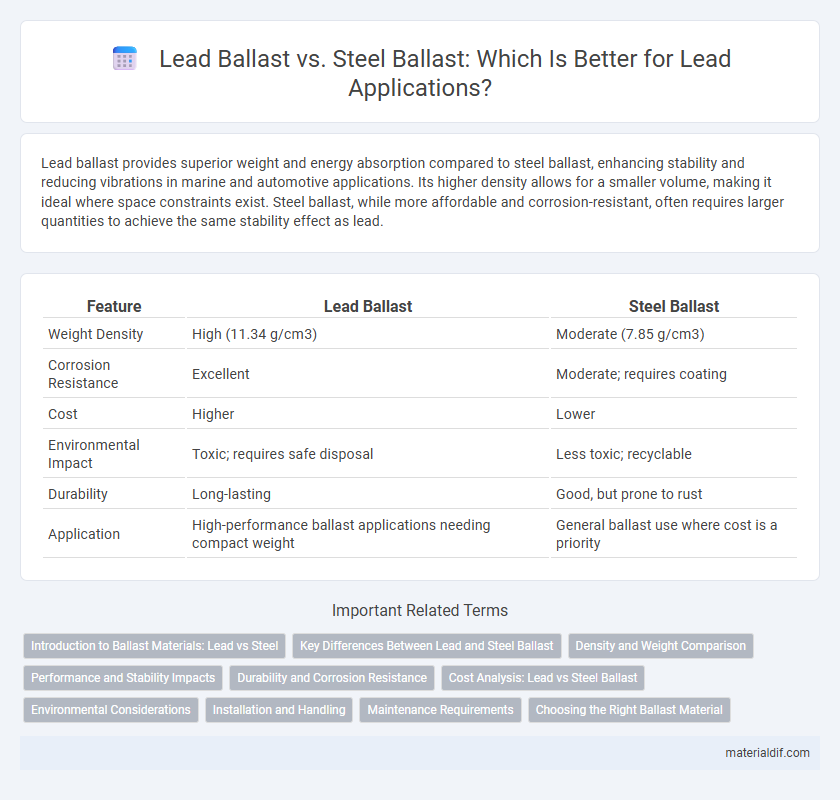

| Feature | Lead Ballast | Steel Ballast |

|---|---|---|

| Weight Density | High (11.34 g/cm3) | Moderate (7.85 g/cm3) |

| Corrosion Resistance | Excellent | Moderate; requires coating |

| Cost | Higher | Lower |

| Environmental Impact | Toxic; requires safe disposal | Less toxic; recyclable |

| Durability | Long-lasting | Good, but prone to rust |

| Application | High-performance ballast applications needing compact weight | General ballast use where cost is a priority |

Introduction to Ballast Materials: Lead vs Steel

Lead ballast offers high density and excellent radiation shielding properties, making it ideal for applications requiring compact weight and protection from radiation. Steel ballast, though less dense than lead, provides greater structural strength and corrosion resistance, often preferred in construction and marine environments. Selection between lead and steel ballast depends on factors such as required density, environmental conditions, and cost efficiency.

Key Differences Between Lead and Steel Ballast

Lead ballast offers higher density and superior weight efficiency compared to steel ballast, enabling more compact designs in applications such as marine and construction. Steel ballast, while less dense, provides cost-effectiveness and resistance to deformation under heavy impacts. Corrosion resistance varies as lead naturally resists rust, whereas steel requires protective coatings or treatments to prevent oxidation.

Density and Weight Comparison

Lead ballast offers a significantly higher density of approximately 11.34 g/cm3 compared to steel's density of around 7.85 g/cm3, allowing for more compact ballast designs. This higher density means lead ballast provides greater weight in a smaller volume, optimizing space and improving stability in applications such as marine or automotive industries. Steel ballast, while less dense, is often chosen for its cost-effectiveness and availability despite requiring larger volumes to achieve equivalent weight.

Performance and Stability Impacts

Lead ballast offers superior density compared to steel ballast, resulting in enhanced vessel stability and lower center of gravity for improved performance. The higher mass per volume of lead enables better weight distribution, reducing pitching and rolling motions in marine applications. Steel ballast, while more cost-effective, provides less stability due to its lower density and may require increased volume to achieve comparable performance.

Durability and Corrosion Resistance

Lead ballast offers superior durability and corrosion resistance compared to steel ballast, maintaining structural integrity over extended periods even in harsh environmental conditions. Its high density reduces volume requirements, while its natural resistance to rust prevents degradation and extends lifespan. Steel ballast, prone to corrosion without protective coatings, often requires maintenance or replacement to ensure long-term performance.

Cost Analysis: Lead vs Steel Ballast

Lead ballast generally incurs higher upfront costs compared to steel ballast due to the material's greater density and market price volatility. Steel ballast offers a more cost-effective solution for large-scale applications, benefiting from lower raw material prices and widespread availability. However, long-term cost considerations should include lead's superior corrosion resistance and durability, which can reduce maintenance expenses over time.

Environmental Considerations

Lead ballast poses significant environmental risks due to its toxicity, potentially contaminating soil and water sources during corrosion or disposal. Steel ballast offers a more sustainable alternative as it is recyclable and less harmful to ecosystems, reducing long-term environmental impact. Choosing steel over lead supports safer handling, minimizes hazardous waste, and aligns with stricter environmental regulations.

Installation and Handling

Lead ballast offers easier installation and handling due to its higher density, requiring less volume to achieve the desired weight compared to steel ballast. Its malleability allows for better conformity to irregular surfaces during placement, reducing gaps and improving stability. Steel ballast, while durable, demands more physical effort and space during installation, potentially complicating handling procedures.

Maintenance Requirements

Lead ballast requires less frequent maintenance due to its corrosion resistance and durability, reducing long-term upkeep costs. Steel ballast, prone to rust and corrosion, demands regular inspections, coatings, and potential replacements to maintain structural integrity. The maintenance requirements of lead ballast make it a more cost-effective and durable choice for applications where longevity is critical.

Choosing the Right Ballast Material

Selecting the right ballast material depends on weight, durability, and environmental impact. Lead ballast offers higher density, allowing for more compact weight distribution, while steel ballast provides greater corrosion resistance and recyclability. Evaluating project requirements and sustainability goals ensures the optimal choice between lead and steel ballast.

Lead ballast vs Steel ballast Infographic

materialdif.com

materialdif.com