Lead shielding offers superior radiation protection compared to concrete shielding due to its high density and atomic number, effectively absorbing X-rays and gamma rays. Unlike concrete, lead is thinner and more space-efficient, making it ideal for environments with limited room while maintaining safety standards. Concrete shielding, while cost-effective and structural, requires significantly greater thickness to achieve similar radiation attenuation as lead.

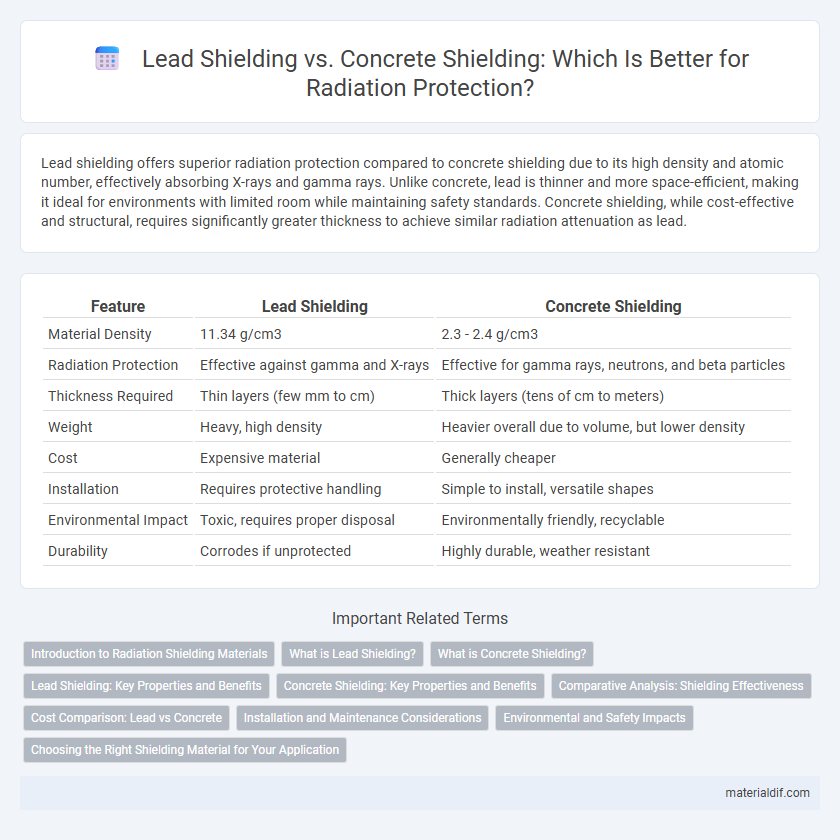

Table of Comparison

| Feature | Lead Shielding | Concrete Shielding |

|---|---|---|

| Material Density | 11.34 g/cm3 | 2.3 - 2.4 g/cm3 |

| Radiation Protection | Effective against gamma and X-rays | Effective for gamma rays, neutrons, and beta particles |

| Thickness Required | Thin layers (few mm to cm) | Thick layers (tens of cm to meters) |

| Weight | Heavy, high density | Heavier overall due to volume, but lower density |

| Cost | Expensive material | Generally cheaper |

| Installation | Requires protective handling | Simple to install, versatile shapes |

| Environmental Impact | Toxic, requires proper disposal | Environmentally friendly, recyclable |

| Durability | Corrodes if unprotected | Highly durable, weather resistant |

Introduction to Radiation Shielding Materials

Lead shielding offers superior density and atomic number, making it highly effective in attenuating gamma rays and X-rays compared to concrete shielding. Concrete shielding relies on thickness and mass to absorb radiation, providing a cost-effective solution for lower-energy radiation and neutron protection. Selecting between lead and concrete depends on radiation type, energy levels, and structural requirements for optimal safety.

What is Lead Shielding?

Lead shielding is a high-density protective barrier used extensively in radiation protection to absorb and block harmful ionizing radiation. Its superior atomic number and density make it more effective than concrete shielding in stopping X-rays and gamma rays in medical, industrial, and nuclear applications. Lead shielding provides compact, efficient radiation attenuation, crucial in environments requiring space-saving yet reliable protection.

What is Concrete Shielding?

Concrete shielding is a radiation protection method that uses dense, reinforced concrete to absorb and attenuate ionizing radiation, particularly gamma rays and x-rays. Its effectiveness depends on the thickness, density, and composition of the concrete, often enhanced by additives like barite or iron to increase radiation absorption. Commonly used in medical facilities, nuclear reactors, and industrial environments, concrete shielding offers structural support and cost efficiency compared to lead, especially for high-energy radiation scenarios.

Lead Shielding: Key Properties and Benefits

Lead shielding offers superior radiation attenuation due to its high density and atomic number, effectively blocking X-rays and gamma rays in medical, industrial, and nuclear applications. Its malleability enables custom shapes and easy installation, providing better space efficiency compared to bulky concrete shielding. Lead's durability and resistance to corrosion ensure long-term protection with minimal maintenance, making it a preferred choice for critical radiation safety environments.

Concrete Shielding: Key Properties and Benefits

Concrete shielding offers superior neutron attenuation compared to lead due to its hydrogen content, making it highly effective in nuclear and radiation protection applications. Its density and customizable composition enable tailored shielding solutions that balance cost, weight, and protection levels, while also providing excellent structural support. Concrete is fire-resistant, durable, and environmentally friendly, enhancing safety and longevity in nuclear facilities and medical radiation environments.

Comparative Analysis: Shielding Effectiveness

Lead shielding offers superior attenuation of gamma rays and X-rays due to its high atomic number and density, requiring thinner layers compared to concrete for equivalent protection. Concrete shielding, while thicker and bulkier, provides effective attenuation of neutrons alongside gamma radiation, benefiting from its hydrogen content and structural versatility. Comparative analysis reveals lead's efficiency in space-constrained environments and concrete's advantage in cost-effectiveness and multifunctional use in radiation protection.

Cost Comparison: Lead vs Concrete

Lead shielding presents a higher material cost compared to concrete, but requires significantly less thickness to achieve equivalent radiation protection, potentially reducing structural expenses. Concrete, while more affordable per cubic meter, demands greater volume and space to match lead's shielding effectiveness, which can increase overall project costs. When evaluating total expenses, factors like installation complexity, space constraints, and long-term maintenance determine whether lead or concrete provides more cost-efficient radiation shielding.

Installation and Maintenance Considerations

Lead shielding offers superior radiation attenuation with easier installation due to its flexibility and thinner profile compared to concrete shielding, which requires extensive formwork and curing time. Maintenance for lead shielding involves periodic inspection for corrosion and physical damage, while concrete shielding demands ongoing structural integrity assessments and potential repair of cracks or spalls. Both materials require specialized handling, but lead's lightweight nature simplifies modifications and replacements during facility upgrades.

Environmental and Safety Impacts

Lead shielding offers superior radiation attenuation with a smaller thickness compared to concrete shielding, reducing structural load and space requirements in medical and industrial environments. However, lead presents significant environmental risks due to its toxicity and potential for contamination during disposal or accidental damage. Concrete shielding, while less effective per unit thickness, is more environmentally benign and safer to handle, making it a preferred option in settings prioritizing ecological sustainability and long-term safety.

Choosing the Right Shielding Material for Your Application

Lead shielding offers superior radiation attenuation due to its high density and atomic number, making it ideal for medical and industrial applications requiring compact protection. Concrete shielding provides cost-effective, structural support with versatile thickness adjustments suitable for large-scale installations such as nuclear power plants and radiation therapy rooms. Selecting the right material depends on factors like radiation type, space constraints, budget, and required protection level for optimal safety performance.

Lead Shielding vs Concrete Shielding Infographic

materialdif.com

materialdif.com