Lead shielding provides effective radiation protection due to its high density and atomic number, making it ideal for blocking gamma rays and X-rays. Lead composite shielding combines lead with other materials to reduce weight while maintaining comparable protective properties, enhancing comfort and mobility. These composites are often used in medical and industrial applications where lightweight yet durable radiation barriers are essential.

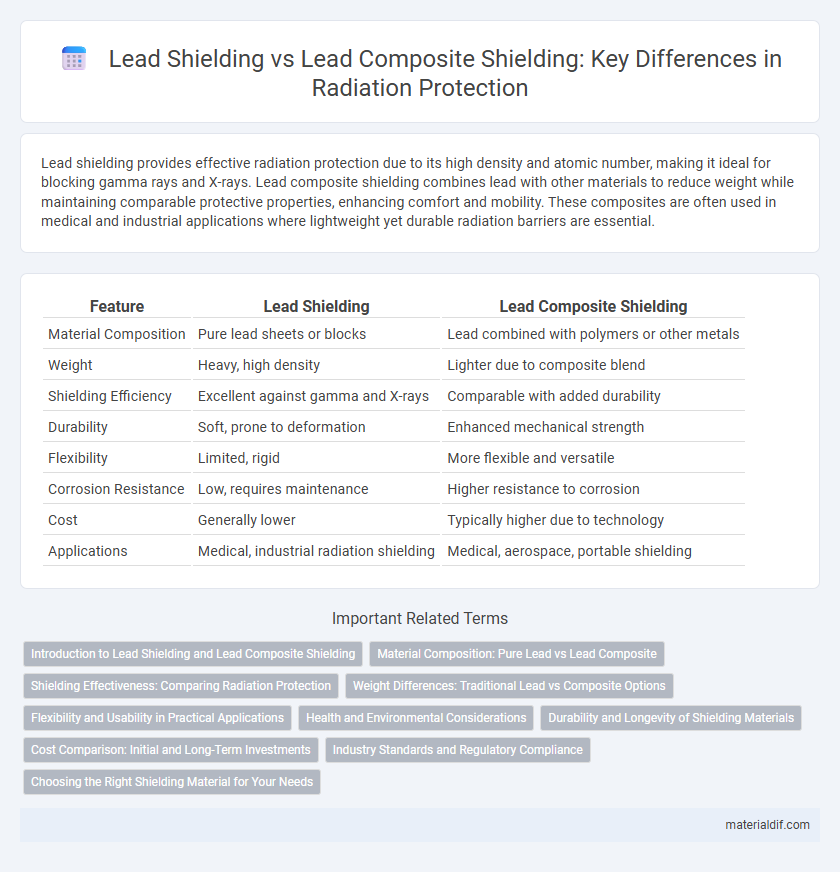

Table of Comparison

| Feature | Lead Shielding | Lead Composite Shielding |

|---|---|---|

| Material Composition | Pure lead sheets or blocks | Lead combined with polymers or other metals |

| Weight | Heavy, high density | Lighter due to composite blend |

| Shielding Efficiency | Excellent against gamma and X-rays | Comparable with added durability |

| Durability | Soft, prone to deformation | Enhanced mechanical strength |

| Flexibility | Limited, rigid | More flexible and versatile |

| Corrosion Resistance | Low, requires maintenance | Higher resistance to corrosion |

| Cost | Generally lower | Typically higher due to technology |

| Applications | Medical, industrial radiation shielding | Medical, aerospace, portable shielding |

Introduction to Lead Shielding and Lead Composite Shielding

Lead shielding offers excellent protection against gamma radiation and X-rays due to its high density and atomic number, making it a standard choice in medical and industrial applications. Lead composite shielding combines lead with other materials like rubber or polymers, enhancing flexibility and reducing weight while maintaining effective radiation attenuation. Innovations in lead composite shielding aim to improve user comfort and compliance without compromising radiation safety standards.

Material Composition: Pure Lead vs Lead Composite

Pure lead shielding consists primarily of elemental lead, offering high density and excellent radiation attenuation properties, ideal for blocking gamma and X-rays. Lead composite shielding integrates lead with other materials such as polymers or metals, enhancing mechanical strength, flexibility, and reducing weight while maintaining effective radiation protection. The choice between pure lead and lead composite depends on specific applications requiring either maximum density or improved durability and ease of handling.

Shielding Effectiveness: Comparing Radiation Protection

Lead shielding offers high-density protection against gamma rays and x-rays, providing effective attenuation of ionizing radiation due to its high atomic number and density. Lead composite shielding combines lead with polymers or other materials, enhancing durability and reducing weight while maintaining comparable radiation attenuation levels. Studies show lead composite shields can achieve similar shielding effectiveness to pure lead, particularly in medical and industrial radiography applications.

Weight Differences: Traditional Lead vs Composite Options

Lead shielding typically offers superior radiation protection but is significantly heavier, posing challenges in transportation and installation. Lead composite shielding incorporates materials such as tungsten and polymers, reducing overall weight by up to 40% while maintaining comparable attenuation properties. The lighter composite options improve handling efficiency and structural support requirements in medical and industrial radiation environments.

Flexibility and Usability in Practical Applications

Lead composites offer enhanced flexibility compared to traditional lead shielding, allowing for easier customization and contouring around complex shapes in practical applications. This flexibility improves usability in environments requiring frequent adjustments or where ergonomic design is crucial, such as medical imaging or radiation therapy rooms. Traditional lead shielding, while effective in radiation protection, tends to be rigid and cumbersome, limiting its practical adaptability and ease of handling in dynamic settings.

Health and Environmental Considerations

Lead shielding offers high radiation protection but poses significant health risks due to lead's toxicity, which can cause neurological damage and environmental contamination during manufacturing and disposal. Lead composite shielding reduces these hazards by combining lead with safer materials, minimizing lead exposure and environmental impact while maintaining effective radiation attenuation. Choosing lead composite shielding aligns with stricter health regulations and sustainability goals by lowering hazardous waste and enhancing worker safety.

Durability and Longevity of Shielding Materials

Lead composite shielding offers enhanced durability compared to traditional lead shielding due to its combination of lead with polymers or other reinforcing materials, which reduces brittleness and improves resistance to wear. The longevity of lead composite shields surpasses that of pure lead as they are less prone to deformation, corrosion, and cracking over time. This makes lead composite shielding a preferred choice for environments requiring sustained radiation protection with minimal maintenance.

Cost Comparison: Initial and Long-Term Investments

Lead shielding typically requires a lower initial investment due to the material's widespread availability and straightforward manufacturing process, but it may involve higher long-term costs related to corrosion, maintenance, and disposal. Lead composite shielding, while more expensive upfront because of advanced materials and complex fabrication, offers enhanced durability, reduced environmental hazards, and lower maintenance expenses, ultimately providing better cost efficiency over its lifespan. Evaluating these factors is crucial for institutions aiming to balance budget constraints with effective radiation protection solutions.

Industry Standards and Regulatory Compliance

Lead shielding provides effective radiation protection but often faces limitations regarding weight and environmental concerns. Lead composite shielding, incorporating materials like tungsten or polymers, meets or exceeds industry standards such as ANSI N43.3 and NRC regulations while offering enhanced durability and reduced toxicity. Regulatory compliance mandates testing for attenuation coefficients and structural integrity, where lead composites increasingly demonstrate superior performance in healthcare and nuclear industries.

Choosing the Right Shielding Material for Your Needs

Lead shielding offers high-density protection against gamma rays and X-rays, making it a reliable choice for medical and industrial applications requiring intense radiation blocking. Lead composite shielding incorporates materials like polymers or tungsten to reduce weight while maintaining effective radiation attenuation, enhancing user comfort and mobility. Selecting the right shielding depends on the balance between protection level, weight, and application environment to optimize safety and efficiency.

Lead shielding vs Lead composite shielding Infographic

materialdif.com

materialdif.com