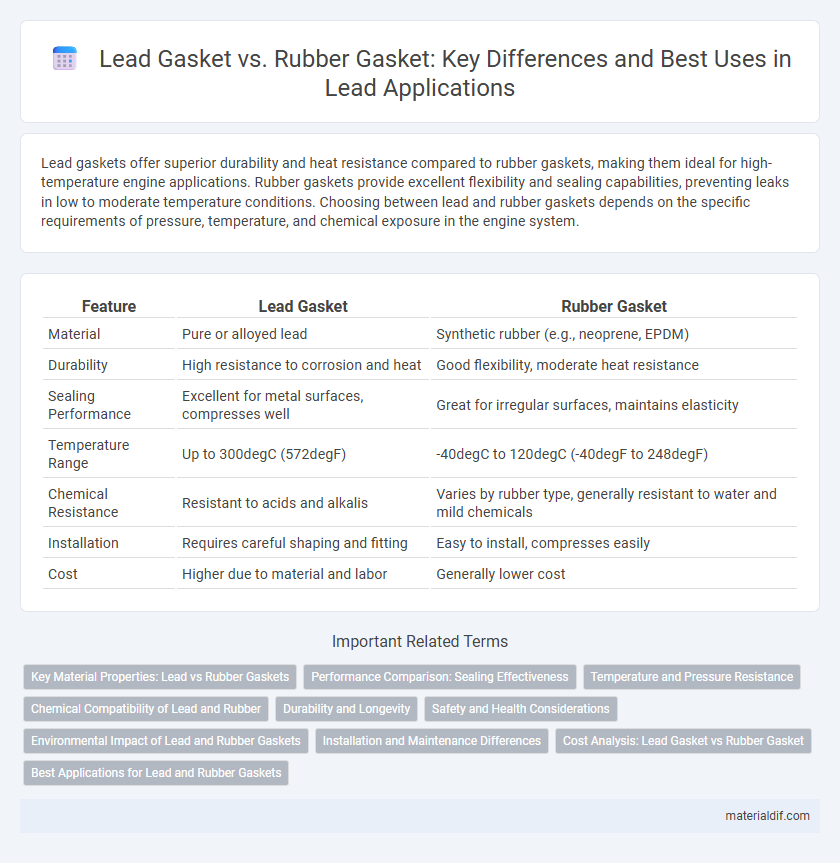

Lead gaskets offer superior durability and heat resistance compared to rubber gaskets, making them ideal for high-temperature engine applications. Rubber gaskets provide excellent flexibility and sealing capabilities, preventing leaks in low to moderate temperature conditions. Choosing between lead and rubber gaskets depends on the specific requirements of pressure, temperature, and chemical exposure in the engine system.

Table of Comparison

| Feature | Lead Gasket | Rubber Gasket |

|---|---|---|

| Material | Pure or alloyed lead | Synthetic rubber (e.g., neoprene, EPDM) |

| Durability | High resistance to corrosion and heat | Good flexibility, moderate heat resistance |

| Sealing Performance | Excellent for metal surfaces, compresses well | Great for irregular surfaces, maintains elasticity |

| Temperature Range | Up to 300degC (572degF) | -40degC to 120degC (-40degF to 248degF) |

| Chemical Resistance | Resistant to acids and alkalis | Varies by rubber type, generally resistant to water and mild chemicals |

| Installation | Requires careful shaping and fitting | Easy to install, compresses easily |

| Cost | Higher due to material and labor | Generally lower cost |

Key Material Properties: Lead vs Rubber Gaskets

Lead gaskets offer superior malleability and excellent resistance to high temperatures and chemical corrosion, making them ideal for heavy-duty sealing applications in engines and industrial machinery. Rubber gaskets, derived from materials like neoprene or silicone, provide outstanding flexibility, compression recovery, and resistance to water and mild chemicals, suitable for dynamic and low-pressure environments. The key material properties highlight lead's durability and heat tolerance, whereas rubber emphasizes elasticity and environmental resistance.

Performance Comparison: Sealing Effectiveness

Lead gaskets provide superior sealing effectiveness due to their high malleability, allowing them to conform tightly to uneven surfaces and withstand high temperatures and pressures. Rubber gaskets excel in flexibility and chemical resistance but may degrade under extreme heat or pressure, leading to potential leaks. In applications demanding high-performance sealing, lead gaskets generally outperform rubber gaskets by maintaining a more reliable, long-lasting seal.

Temperature and Pressure Resistance

Lead gaskets exhibit superior temperature resistance, enduring extreme heat up to 650degC (1200degF), making them ideal for high-temperature engine and exhaust applications. Rubber gaskets offer moderate temperature resistance, generally up to 120degC (248degF), suitable for low to medium temperature systems but can degrade under intense heat. In terms of pressure resistance, lead gaskets provide excellent sealing under high pressure conditions, whereas rubber gaskets perform well under low to moderate pressure but may fail in high-pressure environments.

Chemical Compatibility of Lead and Rubber

Lead gaskets exhibit exceptional chemical resistance to corrosive acids, alkalis, and solvents, making them ideal for applications involving aggressive chemicals. Rubber gaskets, depending on the polymer type such as EPDM or Viton, offer variable chemical compatibility with oils, fuels, and mild acids but can degrade when exposed to strong solvents or high pH environments. Understanding the chemical exposure in the sealing environment is crucial for selecting either lead or rubber gaskets to ensure durability and leak prevention.

Durability and Longevity

Lead gaskets offer superior durability due to their malleability and resistance to high temperatures, making them ideal for heavy-duty applications such as automotive engines and industrial machinery. Rubber gaskets provide excellent flexibility and sealing properties but generally have a shorter lifespan because they degrade faster under heat and chemical exposure. In terms of longevity, lead gaskets outperform rubber gaskets by maintaining effective seals over extended periods in harsh operating conditions.

Safety and Health Considerations

Lead gaskets exhibit excellent chemical resistance and durability but pose significant health risks due to lead's toxicity and potential for causing lead poisoning upon prolonged exposure or improper handling. Rubber gaskets, often made from materials like EPDM or Nitrile, provide safer alternatives with lower toxicity and flexibility, reducing risks related to chemical exposure and allergic reactions. Prioritizing rubber gaskets over lead gaskets in applications where human contact or environmental contamination is possible enhances overall safety and health compliance.

Environmental Impact of Lead and Rubber Gaskets

Lead gaskets release toxic lead particles into the environment during manufacturing and disposal, posing significant health risks and soil contamination. Rubber gaskets, typically made from synthetic or natural elastomers, offer improved biodegradability and do not emit heavy metals, reducing their ecological footprint. Choosing rubber over lead gaskets supports sustainable practices by minimizing hazardous waste and promoting safer recycling processes.

Installation and Maintenance Differences

Lead gaskets offer superior malleability and conformability during installation, ensuring a tight seal on uneven or rough surfaces compared to rubber gaskets, which require precise surface conditions to prevent leaks. Maintenance of lead gaskets often involves less frequent replacement due to their resistance to high temperatures and chemical corrosion, while rubber gaskets may degrade faster under similar conditions, necessitating regular inspection and replacement. Installation of rubber gaskets is typically quicker but demands careful handling to avoid over-tightening or damage, whereas lead gaskets require skilled craftsmanship to shape and install properly.

Cost Analysis: Lead Gasket vs Rubber Gasket

Lead gaskets typically have a higher upfront cost compared to rubber gaskets due to the material expense and manufacturing process. Rubber gaskets offer a cost-effective solution with lower production costs and easier installation, making them ideal for budget-sensitive applications. Over time, lead gaskets may incur additional costs related to maintenance and environmental compliance, while rubber gaskets generally provide longer durability and reduced replacement frequency, enhancing overall cost efficiency.

Best Applications for Lead and Rubber Gaskets

Lead gaskets excel in high-temperature and high-pressure environments such as steam engines, boilers, and industrial machinery due to their excellent malleability and corrosion resistance. Rubber gaskets are ideal for applications requiring flexibility and airtight seals in automotive engines, plumbing systems, and HVAC units, benefiting from their resilience and ability to accommodate surface irregularities. Choosing between lead and rubber gaskets depends on specific conditions like temperature, chemical exposure, and mechanical stress in the sealing application.

Lead gasket vs Rubber gasket Infographic

materialdif.com

materialdif.com