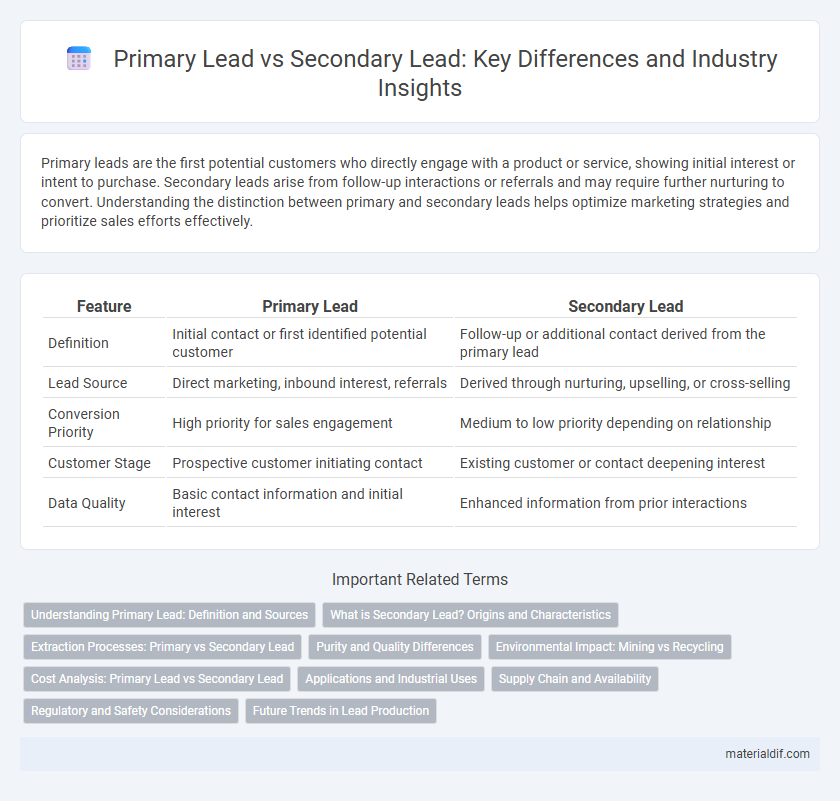

Primary leads are the first potential customers who directly engage with a product or service, showing initial interest or intent to purchase. Secondary leads arise from follow-up interactions or referrals and may require further nurturing to convert. Understanding the distinction between primary and secondary leads helps optimize marketing strategies and prioritize sales efforts effectively.

Table of Comparison

| Feature | Primary Lead | Secondary Lead |

|---|---|---|

| Definition | Initial contact or first identified potential customer | Follow-up or additional contact derived from the primary lead |

| Lead Source | Direct marketing, inbound interest, referrals | Derived through nurturing, upselling, or cross-selling |

| Conversion Priority | High priority for sales engagement | Medium to low priority depending on relationship |

| Customer Stage | Prospective customer initiating contact | Existing customer or contact deepening interest |

| Data Quality | Basic contact information and initial interest | Enhanced information from prior interactions |

Understanding Primary Lead: Definition and Sources

Primary lead originates directly from mining ores that contain lead-bearing minerals such as galena, representing the initial source of lead before any recycling or reprocessing occurs. Key sources of primary lead include underground and open-pit mines where lead sulfide ore is extracted and then subjected to smelting and refining to produce pure lead metal. Understanding the extraction and processing of primary lead is essential as it offers insight into the raw material base influencing global lead supply and pricing dynamics.

What is Secondary Lead? Origins and Characteristics

Secondary lead refers to lead that is recycled from scrap materials, such as used batteries, industrial waste, and other lead-containing products. Its origins are primarily from lead-acid battery recycling processes and recovered lead from manufacturing by-products. Characteristically, secondary lead has comparable purity to primary lead but involves lower energy consumption and environmental impact due to its recycled nature.

Extraction Processes: Primary vs Secondary Lead

Primary lead is extracted directly from lead ore through mining and smelting processes, involving ore beneficiation, roasting, and reduction in blast furnaces. Secondary lead is recovered from recycled lead-containing materials like batteries and scrap, using processes such as dismantling, smelting, and refining to recover lead with lower energy consumption and environmental impact. The extraction of primary lead relies on mineral processing of galena, while secondary lead extraction prioritizes resource conservation and waste reduction through recycling technologies.

Purity and Quality Differences

Primary lead is extracted directly from ore, resulting in higher purity levels typically above 99.9%, making it ideal for applications requiring superior quality such as batteries and radiation shielding. Secondary lead, recycled from scrap and used materials, often contains impurities due to mixed sources, which can affect its overall quality despite being more cost-effective and environmentally sustainable.

Environmental Impact: Mining vs Recycling

Primary lead production from mining operations generates significant environmental concerns, including habitat destruction, soil contamination, and high greenhouse gas emissions due to ore extraction and smelting processes. Secondary lead produced through recycling reduces environmental impact by conserving natural resources, lowering energy consumption by up to 85%, and minimizing hazardous waste generation. Recycling lead batteries and scrap metals plays a crucial role in mitigating pollution and reducing the carbon footprint associated with lead manufacturing.

Cost Analysis: Primary Lead vs Secondary Lead

Primary lead production typically incurs higher costs due to the energy-intensive extraction and refining processes required to obtain lead directly from ores. Secondary lead, recycled from scrap lead materials such as batteries, offers significant cost savings by reducing raw material and energy expenses. Analyzing cost factors reveals that secondary lead production can be up to 40-60% cheaper than primary lead extraction, making it a more economically sustainable option.

Applications and Industrial Uses

Primary lead, extracted from mined ore such as galena, is predominantly used in lead-acid batteries, radiation shielding, and cable sheathing due to its high purity and consistent quality. Secondary lead, recycled from scrap materials including spent batteries and industrial waste, serves as a cost-effective and environmentally sustainable source primarily utilized in battery manufacturing, ammunition, and construction materials. Both lead types are essential in electronics, automotive industries, and construction, with secondary lead providing a significant contribution to reducing environmental impact through resource recovery.

Supply Chain and Availability

Primary lead is extracted directly from mined ores, ensuring a consistent and controlled supply critical for industrial manufacturing and supply chain stability. Secondary lead is recycled from scrap batteries and other lead-containing materials, providing a sustainable and cost-effective alternative that alleviates pressure on raw material extraction. Balancing primary and secondary lead sources enhances overall lead availability while supporting environmental objectives and reducing supply chain risks.

Regulatory and Safety Considerations

Primary lead production involves extracting lead from ores through mining and smelting processes, governed by stringent environmental regulations to control emissions of lead particulates and sulfur dioxide, minimizing air and water pollution. Secondary lead production, which recycles lead from used batteries and scrap, faces rigorous safety standards to prevent worker exposure to toxic lead dust and fumes, adhering to OSHA and EPA guidelines for workplace safety and waste management. Both processes require compliance with hazardous waste handling protocols and continuous monitoring to reduce health risks and environmental contamination.

Future Trends in Lead Production

Future trends in lead production emphasize sustainable extraction methods and recycling technologies, with secondary lead from recycled batteries expected to dominate supply chains. Innovations in hydrometallurgical processes enhance the efficiency and environmental impact of secondary lead recovery compared to traditional primary lead smelting. The growing regulatory pressure to reduce carbon emissions will accelerate the shift towards secondary lead, minimizing reliance on primary lead mining and promoting circular economy practices.

Primary lead vs Secondary lead Infographic

materialdif.com

materialdif.com