Lead flashing offers superior durability and weather resistance, making it a preferred choice for long-lasting roof protection. Rubber flashing provides flexibility and ease of installation, ideal for complex roof shapes and quick repairs. Both materials are essential for waterproofing, but lead flashing excels in longevity while rubber flashing is valued for its adaptability.

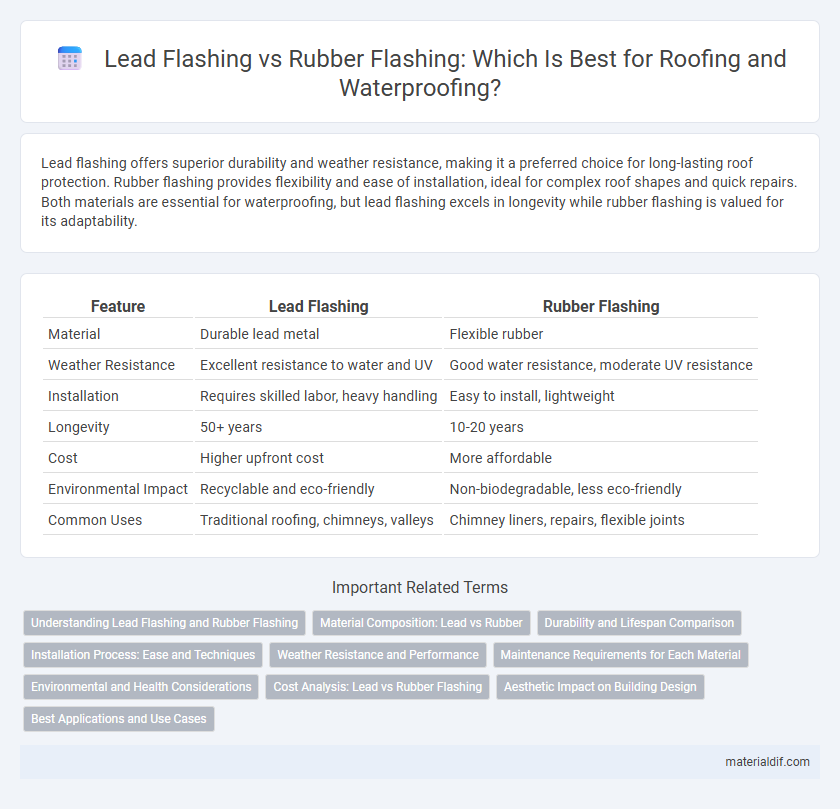

Table of Comparison

| Feature | Lead Flashing | Rubber Flashing |

|---|---|---|

| Material | Durable lead metal | Flexible rubber |

| Weather Resistance | Excellent resistance to water and UV | Good water resistance, moderate UV resistance |

| Installation | Requires skilled labor, heavy handling | Easy to install, lightweight |

| Longevity | 50+ years | 10-20 years |

| Cost | Higher upfront cost | More affordable |

| Environmental Impact | Recyclable and eco-friendly | Non-biodegradable, less eco-friendly |

| Common Uses | Traditional roofing, chimneys, valleys | Chimney liners, repairs, flexible joints |

Understanding Lead Flashing and Rubber Flashing

Lead flashing offers superior durability and weather resistance, making it ideal for long-term roof protection and effective sealing around chimneys and vents. Rubber flashing, made from flexible EPDM or similar materials, provides easier installation and excellent adaptability to complex roof shapes, reducing the risk of leaks. Choosing between lead and rubber flashing depends on project requirements, expected lifespan, and environmental exposure.

Material Composition: Lead vs Rubber

Lead flashing consists of high-density, malleable metal composed primarily of lead, offering excellent durability and weather resistance for roofing applications. Rubber flashing, made from synthetic elastomeric compounds such as EPDM or neoprene, provides flexibility and ease of installation while being resistant to UV rays and temperature fluctuations. The choice between lead and rubber flashing depends on project requirements for long-term performance, environmental considerations, and material adaptability to roof surfaces.

Durability and Lifespan Comparison

Lead flashing offers exceptional durability with a lifespan exceeding 75 years due to its robustness and resistance to weathering and UV exposure. Rubber flashing, while easier to install and more flexible, typically lasts between 20 to 30 years and can degrade faster in extreme temperatures or prolonged sunlight. Choosing lead flashing ensures long-term protection against water ingress with minimal maintenance, outperforming rubber in terms of lifespan and structural integrity.

Installation Process: Ease and Techniques

Lead flashing installation involves precise shaping and securing of malleable lead sheets to roof joints, requiring skilled handcrafting and soldering for waterproofing. Rubber flashing offers a simpler installation with flexible, pre-formed seals that adhere easily to surfaces, reducing labor time and the need for specialized tools. The choice between lead and rubber flashing depends on project complexity, desired durability, and contractor expertise in traditional versus modern sealing techniques.

Weather Resistance and Performance

Lead flashing offers superior weather resistance due to its durability, flexibility, and ability to conform to complex roof profiles, ensuring long-term protection against water infiltration. Rubber flashing provides excellent elasticity and UV resistance, adapting well to structural movements while resisting cracking and deterioration. Both materials perform effectively in diverse weather conditions, but lead flashing generally ensures a longer lifespan in extreme climates.

Maintenance Requirements for Each Material

Lead flashing requires minimal maintenance due to its durability, corrosion resistance, and self-healing properties when scratched, making it ideal for long-term applications. Rubber flashing demands regular inspections for signs of cracking, UV damage, or deterioration, especially in harsh weather, and may require replacement every 10-15 years to maintain its effectiveness. Proper upkeep of both materials ensures optimal waterproofing performance and extends the lifespan of the flashing installations.

Environmental and Health Considerations

Lead flashing poses significant environmental risks due to its toxicity and potential to leach harmful substances into soil and water, impacting ecosystems and human health. Rubber flashing offers a safer alternative with lower environmental impact, being free from heavy metals and more easily recyclable. Choosing rubber flashing reduces exposure to hazardous materials, aligning with modern health regulations and sustainability goals.

Cost Analysis: Lead vs Rubber Flashing

Lead flashing is generally more expensive upfront due to material costs, averaging $250 to $400 per linear foot, while rubber flashing costs range from $50 to $150 per linear foot. Installation of lead flashing requires skilled labor and specialized tools, increasing overall expenses, whereas rubber flashing is easier and quicker to install, reducing labor costs. Despite higher initial costs, lead flashing offers exceptional durability and longevity, often lasting over 50 years, whereas rubber flashing has a shorter lifespan of around 10 to 20 years, potentially leading to more frequent replacements and maintenance costs.

Aesthetic Impact on Building Design

Lead flashing offers a traditional, high-quality finish that seamlessly blends with classic and historic architecture, enhancing the building's aesthetic appeal through its natural patina and durability. Rubber flashing provides a modern, flexible alternative that is less visually obtrusive but may lack the authentic charm and longevity that lead delivers in architectural detailing. Choosing between lead and rubber flashing significantly influences the visual harmony and perceived value of the building's exterior design.

Best Applications and Use Cases

Lead flashing offers superior durability and weather resistance, making it ideal for traditional roofing, chimneys, and complex roof joints where long-term protection is critical. Rubber flashing provides flexibility and ease of installation, suitable for areas with movement or irregular shapes such as dormer windows and roof penetrations. Choice depends on the specific application requirements: lead flashing excels in high-exposure or heritage projects, while rubber flashing is preferred for retrofits and modern construction demanding quick, adaptable solutions.

Lead flashing vs Rubber flashing Infographic

materialdif.com

materialdif.com