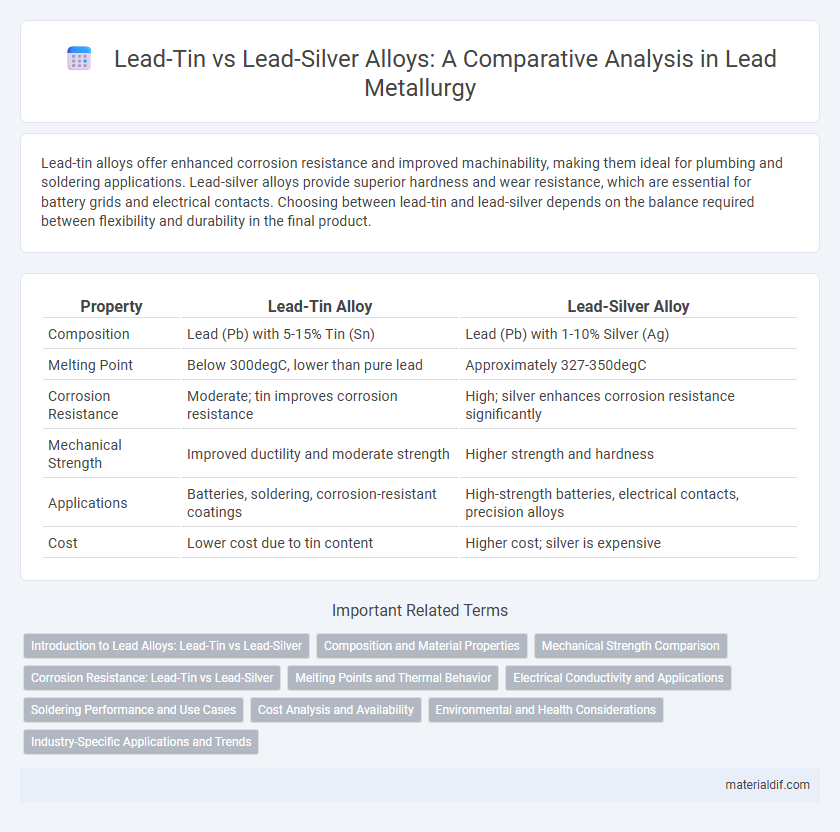

Lead-tin alloys offer enhanced corrosion resistance and improved machinability, making them ideal for plumbing and soldering applications. Lead-silver alloys provide superior hardness and wear resistance, which are essential for battery grids and electrical contacts. Choosing between lead-tin and lead-silver depends on the balance required between flexibility and durability in the final product.

Table of Comparison

| Property | Lead-Tin Alloy | Lead-Silver Alloy |

|---|---|---|

| Composition | Lead (Pb) with 5-15% Tin (Sn) | Lead (Pb) with 1-10% Silver (Ag) |

| Melting Point | Below 300degC, lower than pure lead | Approximately 327-350degC |

| Corrosion Resistance | Moderate; tin improves corrosion resistance | High; silver enhances corrosion resistance significantly |

| Mechanical Strength | Improved ductility and moderate strength | Higher strength and hardness |

| Applications | Batteries, soldering, corrosion-resistant coatings | High-strength batteries, electrical contacts, precision alloys |

| Cost | Lower cost due to tin content | Higher cost; silver is expensive |

Introduction to Lead Alloys: Lead-Tin vs Lead-Silver

Lead-tin and lead-silver alloys serve different industrial purposes due to their unique properties. Lead-tin alloys are preferred for their excellent corrosion resistance and malleability, making them ideal for soldering and plumbing applications. Lead-silver alloys offer superior hardness and increased electrical conductivity, often utilized in battery plates and electrical components.

Composition and Material Properties

Lead-tin alloys primarily consist of lead with varying percentages of tin, enhancing corrosion resistance and mechanical strength, making them suitable for soldering applications. Lead-silver alloys incorporate silver to improve hardness, thermal conductivity, and resistance to fatigue, commonly used in battery grids and high-performance bearings. The distinct compositional differences directly influence their microstructure and electrical conductivity, tailoring each alloy to specific industrial uses.

Mechanical Strength Comparison

Lead-tin alloys exhibit moderate mechanical strength with enhanced ductility, making them suitable for applications requiring flexibility under stress. Lead-silver alloys offer higher mechanical strength and improved wear resistance due to silver's ability to increase hardness and tensile strength. The choice between lead-tin and lead-silver alloys largely depends on the requirement for either toughness or load-bearing capacity in engineering components.

Corrosion Resistance: Lead-Tin vs Lead-Silver

Lead-tin alloys exhibit superior corrosion resistance compared to lead-silver alloys due to the protective oxide layer formed by tin, which minimizes surface degradation in harsh environments. Lead-silver alloys, while offering improved mechanical strength and electrical conductivity, are more prone to corrosion because silver does not provide the same level of passivation as tin. In applications requiring long-term durability against corrosive agents, lead-tin alloys are preferred for their enhanced stability and resistance to electrochemical attack.

Melting Points and Thermal Behavior

Lead-tin alloys exhibit lower melting points, typically around 183degC to 290degC depending on composition, making them ideal for soldering applications. Lead-silver alloys have higher melting points, generally between 300degC and 330degC, providing enhanced thermal stability and resistance to softening at elevated temperatures. The thermal behavior of lead-tin alloys favors easy melting and solidification, while lead-silver alloys maintain structural integrity under higher thermal stress.

Electrical Conductivity and Applications

Lead-silver alloys exhibit higher electrical conductivity compared to lead-tin alloys due to silver's superior electron mobility, enhancing their performance in electrical applications. Lead-tin alloys are commonly used for corrosion-resistant soldering and battery components where mechanical strength and corrosion resistance are prioritized over conductivity. Lead-silver alloys find critical applications in high-performance electrical contacts and batteries requiring efficient current conduction and durability.

Soldering Performance and Use Cases

Lead-tin solder offers excellent wetting properties and a low melting point, making it ideal for general electronics assembly and fine-pitch components. Lead-silver solder provides superior mechanical strength and thermal fatigue resistance, suitable for high-reliability applications in aerospace and automotive sectors. Both alloys deliver strong electrical conductivity, but lead-silver is preferred when enhanced durability and performance under thermal cycling are critical.

Cost Analysis and Availability

Lead-tin alloys generally offer lower raw material costs compared to lead-silver alloys, making them more economical for large-scale manufacturing. Lead-silver alloys, while more expensive due to higher silver content, provide enhanced mechanical and corrosion resistance properties essential for specialized applications. Availability of tin is more consistent and globally widespread than silver, contributing to more stable supply chains and pricing for lead-tin compared to lead-silver alloys.

Environmental and Health Considerations

Lead-tin alloys and lead-silver alloys differ significantly in environmental and health impacts, with lead-tin compounds generally posing higher toxicity risks due to tin's ability to enhance lead solubility and bioavailability. Lead-silver mixtures, often used in battery applications, tend to have slightly reduced leaching potential but still present substantial hazards, including neurotoxicity and environmental contamination. Proper management and disposal protocols are critical to mitigate soil and water pollution risks associated with both alloy types.

Industry-Specific Applications and Trends

Lead-tin alloys dominate the soldering industry due to their superior wetting properties and low melting points, making them ideal for electronic circuit board assembly. Lead-silver alloys are preferred in battery manufacturing and industrial bearing applications because of their enhanced mechanical strength and corrosion resistance. Recent trends show a shift towards lead-free alternatives in electronics, but lead-silver remains crucial in heavy-duty industrial sectors.

Lead-tin vs Lead-silver Infographic

materialdif.com

materialdif.com