Lead is a heavier metal than bronze, making it more suitable for applications requiring weight and density. Bronze, an alloy of copper and tin, offers superior corrosion resistance and durability compared to lead. Choosing between lead and bronze depends on the specific needs of strength, environmental exposure, and weight in pet-related products or projects.

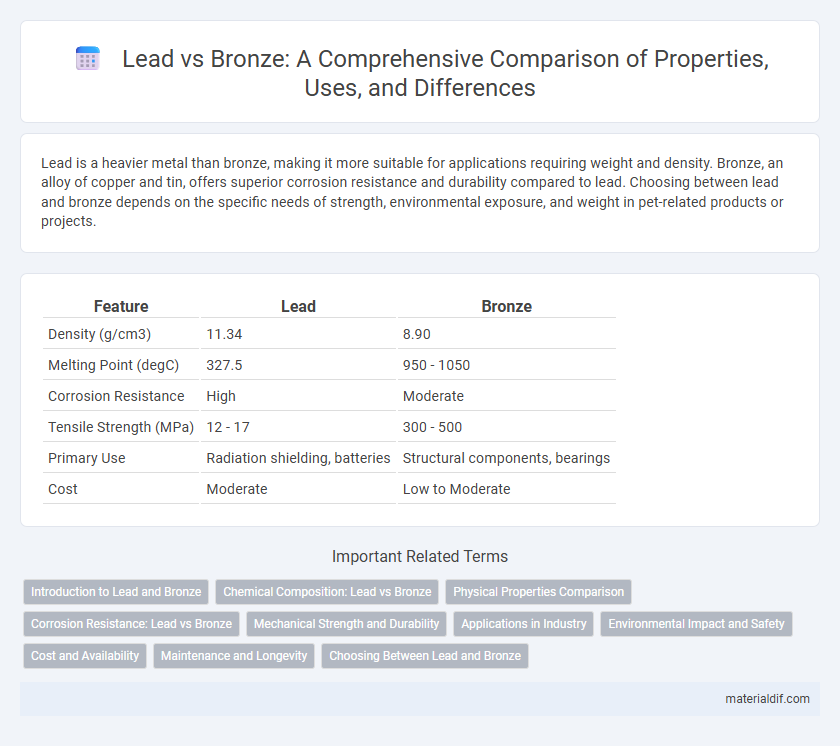

Table of Comparison

| Feature | Lead | Bronze |

|---|---|---|

| Density (g/cm3) | 11.34 | 8.90 |

| Melting Point (degC) | 327.5 | 950 - 1050 |

| Corrosion Resistance | High | Moderate |

| Tensile Strength (MPa) | 12 - 17 | 300 - 500 |

| Primary Use | Radiation shielding, batteries | Structural components, bearings |

| Cost | Moderate | Low to Moderate |

Introduction to Lead and Bronze

Lead is a dense, malleable metal known for its corrosion resistance and high atomic number, making it essential in radiation shielding and batteries. Bronze, an alloy primarily composed of copper and tin, is valued for its hardness, durability, and distinct reddish-brown color, often utilized in sculptures and musical instruments. Understanding Lead and Bronze's unique material properties highlights their varied industrial and artistic applications.

Chemical Composition: Lead vs Bronze

Lead primarily consists of the element lead (Pb) with a purity of nearly 100%, while bronze is an alloy mainly composed of copper (Cu) and tin (Sn), usually with copper making up about 88-95% and tin 5-12%. Lead has a high density of 11.34 g/cm3 and is soft and malleable, whereas bronze exhibits greater hardness and corrosion resistance due to its copper-tin composition. The chemical composition directly influences their mechanical properties, making lead suitable for shielding and weights and bronze ideal for bearings and sculptures.

Physical Properties Comparison

Lead exhibits a higher density of 11.34 g/cm3 compared to bronze, which ranges between 8.7 to 8.9 g/cm3, making lead significantly heavier. Lead's melting point is 327.5degC, considerably lower than bronze, which melts between 950degC and 1050degC, indicating different thermal tolerance. While lead is softer with a Mohs hardness of around 1.5, bronze is much harder, typically ranging from 3 to 4, affecting durability and wear resistance.

Corrosion Resistance: Lead vs Bronze

Lead exhibits superior corrosion resistance compared to bronze, especially in acidic and sulfide-rich environments where it forms a stable oxide layer that protects the metal. Bronze, an alloy of copper and tin, is more susceptible to corrosion due to its copper content, which can oxidize and form patinas over time. In marine or highly corrosive conditions, lead's resistance ensures longer durability and less maintenance than bronze.

Mechanical Strength and Durability

Lead exhibits superior mechanical strength and durability compared to bronze, making it more suitable for applications requiring enhanced resistance to deformation and wear. While bronze offers moderate strength and corrosion resistance, lead's higher density and malleability provide exceptional impact absorption and long-lasting performance in demanding mechanical environments. This makes lead a preferred material in scenarios where prolonged structural integrity and robustness are critical.

Applications in Industry

Lead offers superior radiation shielding, making it indispensable in medical imaging and nuclear power plants, whereas bronze excels in corrosion resistance and machinability, suitable for marine and decorative applications. Industries leverage lead's high density and malleability for batteries and protective equipment, while bronze is favored for bearings and gears due to its durability and low friction. Both materials serve distinct purposes, with lead prioritized for protection against hazardous environments and bronze for structural components requiring long-lasting wear resistance.

Environmental Impact and Safety

Lead exhibits a higher environmental risk compared to bronze due to its toxicity and potential for soil and water contamination during mining and disposal. Bronze, primarily an alloy of copper and tin, is less hazardous and more recyclable, reducing its ecological footprint. In terms of safety, handling lead requires strict protective measures to prevent lead poisoning, whereas bronze poses minimal health risks under normal use.

Cost and Availability

Lead is generally more expensive than bronze due to its higher density and toxicity-related handling costs, impacting its overall price. Bronze is widely available and cost-effective because of its common alloy composition primarily of copper and tin, making it more accessible for various applications. Lead's limited availability and stricter regulations increase its cost and reduce its practicality compared to the abundant and economically viable bronze.

Maintenance and Longevity

Lead offers superior maintenance advantages over bronze due to its higher corrosion resistance and easier reparability, reducing long-term upkeep costs. While bronze is durable, it often requires more frequent maintenance to prevent oxidation and metal fatigue. Lead's enhanced longevity in harsh environments makes it a preferred material for applications demanding sustained structural integrity and minimal maintenance.

Choosing Between Lead and Bronze

Choosing between lead and bronze depends on the desired properties for the application; lead offers superior density and corrosion resistance ideal for radiation shielding and batteries, while bronze provides enhanced strength and resistance to wear, making it suitable for decorative items and mechanical components. Lead is softer and more malleable, lending itself to easy casting and shaping, whereas bronze, an alloy primarily of copper and tin, balances hardness with corrosion resistance, ideal for artistic and structural uses. Consider environmental and health factors since lead is toxic, requiring careful handling, whereas bronze is safer and more durable in outdoor conditions.

Lead vs Bronze Infographic

materialdif.com

materialdif.com