Lead solder offers excellent electrical conductivity and a lower melting point, making it easier to work with in precision electronics assembly. Lead-free solder is preferred for environmental and health reasons, complying with regulations like RoHS, but it typically requires higher temperatures and may be less flexible in joints. Choosing between lead and lead-free solder depends on the specific application, balancing performance needs against safety and regulatory compliance.

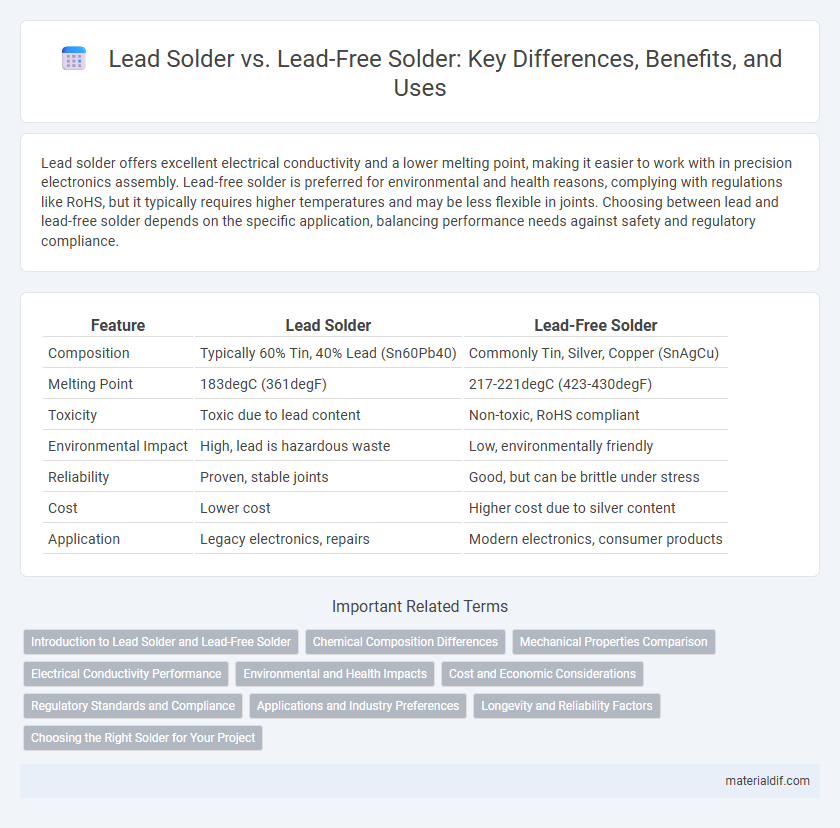

Table of Comparison

| Feature | Lead Solder | Lead-Free Solder |

|---|---|---|

| Composition | Typically 60% Tin, 40% Lead (Sn60Pb40) | Commonly Tin, Silver, Copper (SnAgCu) |

| Melting Point | 183degC (361degF) | 217-221degC (423-430degF) |

| Toxicity | Toxic due to lead content | Non-toxic, RoHS compliant |

| Environmental Impact | High, lead is hazardous waste | Low, environmentally friendly |

| Reliability | Proven, stable joints | Good, but can be brittle under stress |

| Cost | Lower cost | Higher cost due to silver content |

| Application | Legacy electronics, repairs | Modern electronics, consumer products |

Introduction to Lead Solder and Lead-Free Solder

Lead solder, typically composed of tin and lead alloy, has been widely used in electronics for its low melting point and excellent electrical conductivity. Lead-free solder, often made from tin, silver, and copper alloys, offers a safer alternative by eliminating toxic lead content, complying with environmental regulations like RoHS. The transition to lead-free solder addresses health and environmental concerns while maintaining reliable joint quality in modern electronic manufacturing.

Chemical Composition Differences

Lead solder primarily consists of a tin-lead alloy, typically 60% tin and 40% lead, providing low melting points and excellent electrical conductivity. Lead-free solder substitutes lead with metals such as silver, copper, and bismuth, commonly forming alloys like SAC305 (96.5% tin, 3% silver, 0.5% copper) to meet environmental regulations. The chemical composition differences impact melting temperatures, mechanical properties, and compliance with RoHS standards in electronics manufacturing.

Mechanical Properties Comparison

Lead solder typically exhibits superior ductility and tensile strength compared to lead-free solder, providing enhanced mechanical reliability in electronic joints. Lead-free solder often contains alloys like tin-silver-copper, which result in higher hardness and brittleness, potentially compromising fatigue resistance under thermal cycling. Mechanical properties such as shear strength and elongation are generally better in lead solder, making it favorable for applications requiring robust mechanical performance.

Electrical Conductivity Performance

Lead solder typically exhibits higher electrical conductivity compared to lead-free solder alloys, primarily because of the superior conductive properties of tin-lead compositions. Lead-free solders, commonly composed of tin-copper, tin-silver, or tin-silver-copper, often demonstrate slightly reduced electrical conductivity, potentially impacting high-frequency and sensitive electronic applications. The choice between lead and lead-free solder requires balancing electrical performance with environmental regulations and health safety standards.

Environmental and Health Impacts

Lead solder poses significant environmental hazards due to lead's toxicity and potential to contaminate soil and water, causing long-term ecological damage. Lead-free solder, often composed of tin, silver, and copper, reduces health risks by eliminating lead exposure, which is associated with neurological and developmental disorders. Transitioning to lead-free solder supports safer manufacturing practices and complies with regulations like RoHS aimed at minimizing hazardous substances in electronics.

Cost and Economic Considerations

Lead solder generally costs less than lead-free solder due to its simpler alloy composition and longer-established manufacturing processes. Lead-free solder typically incurs higher expenses driven by the use of alternative metals like tin, silver, and copper, which require more complex processing and higher raw material costs. Economic considerations also include regulatory compliance and potential health-related costs, where lead-free solder provides advantages by reducing hazardous material handling and disposal expenses.

Regulatory Standards and Compliance

Lead solder, containing up to 40% lead, faces strict regulatory limitations under directives like RoHS (Restriction of Hazardous Substances) which restrict lead use in electronics to minimize environmental and health impacts. Lead-free solder, typically composed of tin, silver, and copper alloys, complies with international standards such as REACH and RoHS, facilitating global market access and reducing hazardous waste. Compliance with these regulatory standards ensures product safety, environmental sustainability, and adherence to legal requirements in manufacturing and electronics assembly.

Applications and Industry Preferences

Lead solder, prized for its low melting point and excellent electrical conductivity, remains preferred in electronics manufacturing for reliable, strong joints in circuit boards and aerospace components. Lead-free solder, mandated by environmental regulations like RoHS, dominates consumer electronics and automotive industries to reduce toxic lead exposure and promote sustainable production. Industries balancing performance and compliance often choose lead-free alloys in medical devices and telecommunications, reflecting a shift toward eco-friendly materials despite higher melting points and altered wetting properties.

Longevity and Reliability Factors

Lead solder offers superior longevity and reliability due to its lower melting point and better wetting properties, resulting in stronger and more durable joints in electronic assemblies. Lead-free solder, often composed of tin, silver, and copper, tends to have higher melting points, which can cause increased thermal stress and potential joint degradation over time. Despite environmental concerns prompting a shift to lead-free alternatives, lead solder remains preferred in high-reliability applications such as aerospace and military electronics where long-term performance is critical.

Choosing the Right Solder for Your Project

Lead solder offers excellent wetting properties and a lower melting point, making it ideal for delicate electronics and projects requiring precise temperature control. Lead-free solder, typically composed of tin, silver, and copper, provides a safer, environmentally friendly alternative, complying with RoHS regulations and reducing health risks. Selecting the right solder depends on your project's requirements for durability, environmental compliance, and thermal sensitivity.

Lead solder vs Lead-free solder Infographic

materialdif.com

materialdif.com