Lead cable sheathing provides superior protection against moisture, corrosion, and chemical exposure, making it ideal for harsh underground and marine environments. Polyethylene sheathing offers excellent flexibility and resistance to abrasion, often preferred for lighter-duty applications and ease of installation. Choosing between lead and polyethylene sheathing depends on the required durability, environmental conditions, and budget constraints for lead cable projects.

Table of Comparison

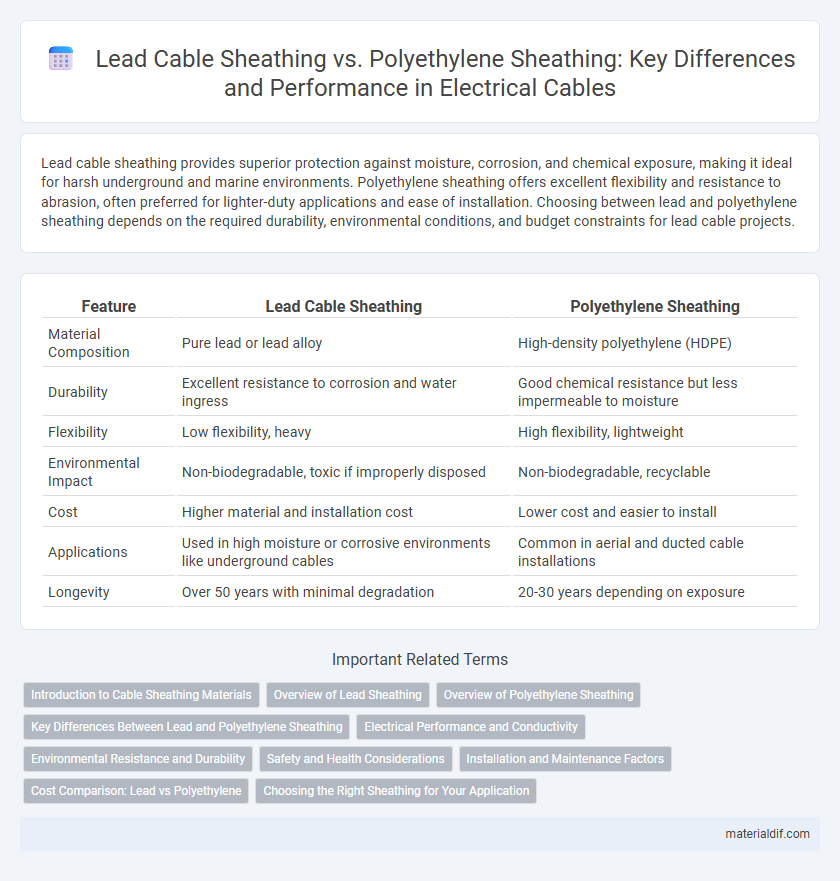

| Feature | Lead Cable Sheathing | Polyethylene Sheathing |

|---|---|---|

| Material Composition | Pure lead or lead alloy | High-density polyethylene (HDPE) |

| Durability | Excellent resistance to corrosion and water ingress | Good chemical resistance but less impermeable to moisture |

| Flexibility | Low flexibility, heavy | High flexibility, lightweight |

| Environmental Impact | Non-biodegradable, toxic if improperly disposed | Non-biodegradable, recyclable |

| Cost | Higher material and installation cost | Lower cost and easier to install |

| Applications | Used in high moisture or corrosive environments like underground cables | Common in aerial and ducted cable installations |

| Longevity | Over 50 years with minimal degradation | 20-30 years depending on exposure |

Introduction to Cable Sheathing Materials

Lead cable sheathing offers superior protection against moisture, corrosion, and mechanical damage, making it ideal for underground and hazardous environments. Polyethylene sheathing provides excellent insulation, flexibility, and resistance to chemicals while being lightweight and cost-effective for general cable protection. Understanding the specific environmental and operational requirements helps determine whether lead or polyethylene sheathing is best suited for a particular cable application.

Overview of Lead Sheathing

Lead cable sheathing provides superior protection against moisture, chemicals, and physical damage due to its dense, malleable properties, making it ideal for underground and industrial cable installations. This protective layer enhances cable longevity by offering excellent corrosion resistance and shielding against electromagnetic interference compared to polyethylene sheathing, which primarily offers lightweight and cost-effective insulation. Lead's durability and impermeability ensure reliable performance in harsh environments, especially where chemical exposure and mechanical stress are significant concerns.

Overview of Polyethylene Sheathing

Polyethylene sheathing offers excellent resistance to moisture, chemicals, and UV radiation, making it an ideal protective layer for lead cables in outdoor and industrial environments. Its lightweight and flexible properties enhance durability while maintaining cable integrity under harsh conditions. This type of sheathing also contributes to cost-effective installation and long-term performance compared to traditional lead cable sheathing.

Key Differences Between Lead and Polyethylene Sheathing

Lead cable sheathing offers superior resistance to moisture, chemicals, and mechanical damage, making it ideal for harsh environmental conditions, whereas polyethylene sheathing provides excellent electrical insulation with lightweight flexibility. Lead sheaths are denser and heavier, providing enhanced protection against rodent attacks and radioactive interference, while polyethylene is more cost-effective and easier to handle during installation. The primary distinction lies in lead's durability and protective qualities versus polyethylene's insulating properties and economy.

Electrical Performance and Conductivity

Lead cable sheathing offers superior electrical performance with excellent conductivity and resistance to moisture, chemicals, and electromagnetic interference, ensuring reliable signal transmission. Polyethylene sheathing provides good insulation properties and chemical resistance but has lower conductivity and can degrade under prolonged exposure to UV light. Choosing lead sheathing enhances durability and electrical stability in harsh environments, while polyethylene is more cost-effective for less demanding applications.

Environmental Resistance and Durability

Lead cable sheathing offers superior environmental resistance due to its exceptional impermeability to moisture, chemicals, and UV radiation, making it highly durable in harsh conditions. Polyethylene sheathing provides good resistance to water and chemicals but may degrade faster under prolonged UV exposure and extreme temperatures. Choosing lead sheathing enhances cable longevity and reliability in environments with aggressive chemical or weather challenges.

Safety and Health Considerations

Lead cable sheathing offers superior resistance to moisture and mechanical damage but poses significant health risks due to lead toxicity, requiring strict handling and disposal protocols. Polyethylene sheathing, while less durable, provides a safer alternative with low toxicity and environmental impact, making it preferable for applications prioritizing human health and regulatory compliance. Safety measures must include monitoring for lead exposure and implementing protective equipment when using lead sheathed cables to minimize health hazards.

Installation and Maintenance Factors

Lead cable sheathing offers superior protection against moisture and chemical corrosion, making it ideal for harsh environments where durability and longevity are critical. Polyethylene sheathing is lighter and more flexible, simplifying installation and reducing labor costs, but it may require more frequent inspections and maintenance to prevent damage in aggressive conditions. Choosing between lead and polyethylene sheathing depends on balancing initial installation ease with long-term maintenance demands and environmental exposure.

Cost Comparison: Lead vs Polyethylene

Lead cable sheathing typically incurs higher initial costs due to the material's density and manufacturing complexity, making it more expensive than polyethylene sheathing. Polyethylene offers a cost-effective alternative with lower raw material and production expenses, contributing to reduced overall installation costs. Long-term durability and environmental considerations also influence the total cost, with lead requiring specialized handling and disposal.

Choosing the Right Sheathing for Your Application

Choosing the right sheathing between lead cable sheathing and polyethylene sheathing depends on application requirements such as environmental protection, flexibility, and durability. Lead sheathing offers excellent resistance to moisture, chemicals, and mechanical damage, making it ideal for underground or harsh industrial environments. Polyethylene sheathing provides lightweight, cost-effective insulation with good abrasion resistance, suited for general electrical wiring and above-ground installations.

Lead Cable Sheathing vs Polyethylene Sheathing Infographic

materialdif.com

materialdif.com