Lead batteries offer a cost-effective solution with high surge current capabilities, making them ideal for applications requiring reliable power bursts. Lithium batteries provide superior energy density, longer lifespan, and lighter weight, enhancing performance in portable and electric vehicle applications. Choosing between lead and lithium batteries depends on the balance between budget constraints, weight considerations, and energy storage needs.

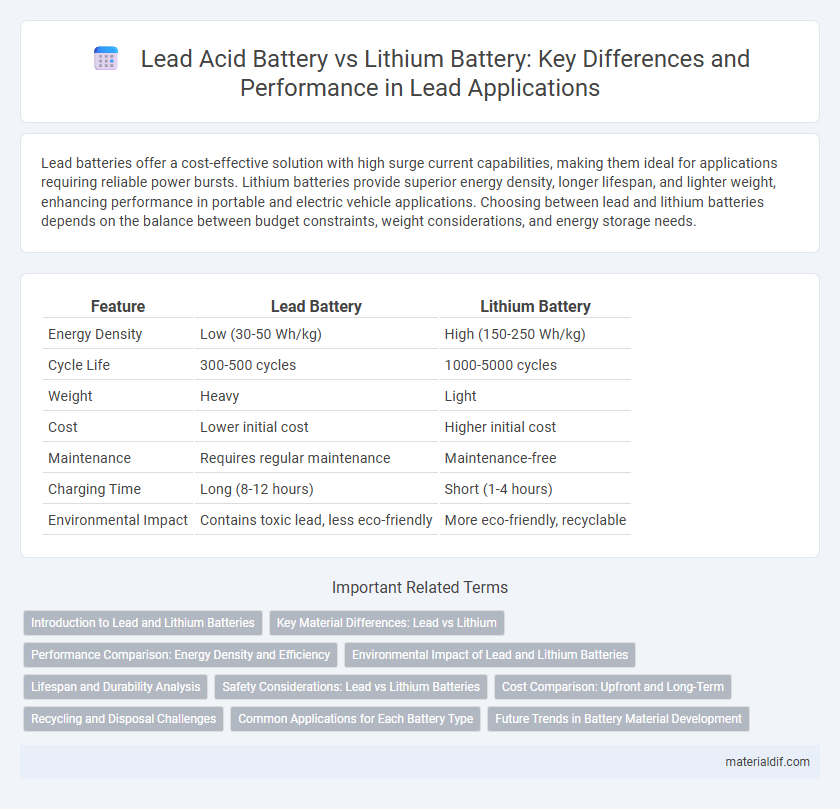

Table of Comparison

| Feature | Lead Battery | Lithium Battery |

|---|---|---|

| Energy Density | Low (30-50 Wh/kg) | High (150-250 Wh/kg) |

| Cycle Life | 300-500 cycles | 1000-5000 cycles |

| Weight | Heavy | Light |

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Requires regular maintenance | Maintenance-free |

| Charging Time | Long (8-12 hours) | Short (1-4 hours) |

| Environmental Impact | Contains toxic lead, less eco-friendly | More eco-friendly, recyclable |

Introduction to Lead and Lithium Batteries

Lead batteries, known for their robust construction and reliable performance, use lead dioxide and sponge lead as electrodes with sulfuric acid electrolyte, making them ideal for automotive and backup power applications. Lithium batteries, featuring lithium metal or lithium-ion chemistry, offer higher energy density, longer cycle life, and faster charging capabilities, making them suitable for portable electronics and electric vehicles. Both battery types serve distinct roles based on energy requirements, cost considerations, and application environments.

Key Material Differences: Lead vs Lithium

Lead batteries use lead dioxide and sponge lead plates immersed in sulfuric acid electrolyte, providing durability and high surge currents but resulting in heavier weight and lower energy density. Lithium batteries rely on lithium metal oxides and graphite electrodes with a lithium-ion electrolyte, offering superior energy density, lighter weight, and longer cycle life. The fundamental material differences dictate performance characteristics, where lead's high mass and chemical composition limit capacity, while lithium's electrochemical properties enable faster charging and greater efficiency.

Performance Comparison: Energy Density and Efficiency

Lead batteries typically offer lower energy density, around 30-50 Wh/kg, compared to lithium batteries which range between 150-250 Wh/kg, making lithium batteries significantly lighter and more compact for the same energy storage. Lithium batteries exhibit higher efficiency with charge/discharge rates exceeding 90%, whereas lead batteries usually operate at 70-85% efficiency, resulting in less energy loss during cycling. This performance difference makes lithium batteries more suitable for applications requiring longer runtimes and faster charging.

Environmental Impact of Lead and Lithium Batteries

Lead batteries pose significant environmental risks due to the toxicity of lead, which can contaminate soil and water if not properly recycled, leading to severe health hazards. Lithium batteries, while less toxic, involve the extraction of lithium and other metals that contribute to resource depletion and environmental degradation, including water pollution and habitat destruction. Proper recycling and sustainable sourcing practices are essential to mitigate the environmental impact of both lead and lithium batteries.

Lifespan and Durability Analysis

Lead batteries typically offer a lifespan of 3 to 5 years with limited deep discharge cycles, whereas lithium batteries can last 8 to 15 years due to superior chemistry and higher cycle tolerance. Lithium batteries exhibit better durability, maintaining capacity above 80% even after 1000 to 2000 charge cycles, while lead batteries degrade faster under similar conditions. The enhanced thermal stability and resistance to sulfation in lithium batteries contribute significantly to their longer lifespan and consistent performance compared to traditional lead-acid alternatives.

Safety Considerations: Lead vs Lithium Batteries

Lead batteries offer robust safety with a lower risk of thermal runaway and explosions compared to lithium batteries, which are prone to overheating and fire hazards if damaged or improperly charged. The stable chemical structure of lead-acid batteries minimizes toxic gas emissions, enhancing workplace safety, while lithium batteries require sophisticated battery management systems to prevent short circuits and thermal events. Proper ventilation and maintenance are critical for lead batteries to avoid acid leaks, whereas lithium batteries demand strict adherence to manufacturing standards to mitigate safety risks.

Cost Comparison: Upfront and Long-Term

Lead batteries have a lower upfront cost compared to lithium batteries, making them more affordable for initial investment. However, lithium batteries offer a longer lifespan and higher energy density, resulting in lower long-term replacement and maintenance costs. Over time, lithium batteries provide a better return on investment despite their higher initial price.

Recycling and Disposal Challenges

Lead batteries present significant recycling advantages due to an established, efficient global recycling infrastructure that recovers up to 99% of lead content, minimizing environmental impact. Lithium battery recycling remains challenging because of complex materials, limited standardized processes, and potential hazards from electrolyte chemicals, leading to lower recovery rates and higher disposal costs. Both battery types require careful handling; however, the widespread establishment of lead battery recycling contrasts with the evolving, less mature lithium battery recycling industry facing increasing demand and regulatory scrutiny.

Common Applications for Each Battery Type

Lead batteries are commonly used in automotive starters, uninterruptible power supplies (UPS), and backup power systems due to their reliability and cost-effectiveness. Lithium batteries dominate consumer electronics, electric vehicles, and renewable energy storage applications because of their high energy density and longer cycle life. Both battery types serve distinct roles in industries requiring energy storage, with lead batteries favored for stationary storage and lithium batteries preferred for portable and high-performance uses.

Future Trends in Battery Material Development

Emerging trends in battery material development prioritize enhancing energy density, lifespan, and environmental sustainability, driving research towards advanced lithium-ion chemistries and solid-state electrolytes that outperform traditional lead batteries. Innovations such as silicon anodes and lithium-sulfur technologies promise significant improvements in charging speed and capacity, positioning lithium batteries as the cornerstone of future energy storage solutions. While lead batteries continue to serve cost-effective, recycling-friendly applications, the shift towards lightweight, high-efficiency lithium variants reflects the evolving demands of electric vehicles and renewable energy systems.

Lead Battery vs Lithium Battery Infographic

materialdif.com

materialdif.com