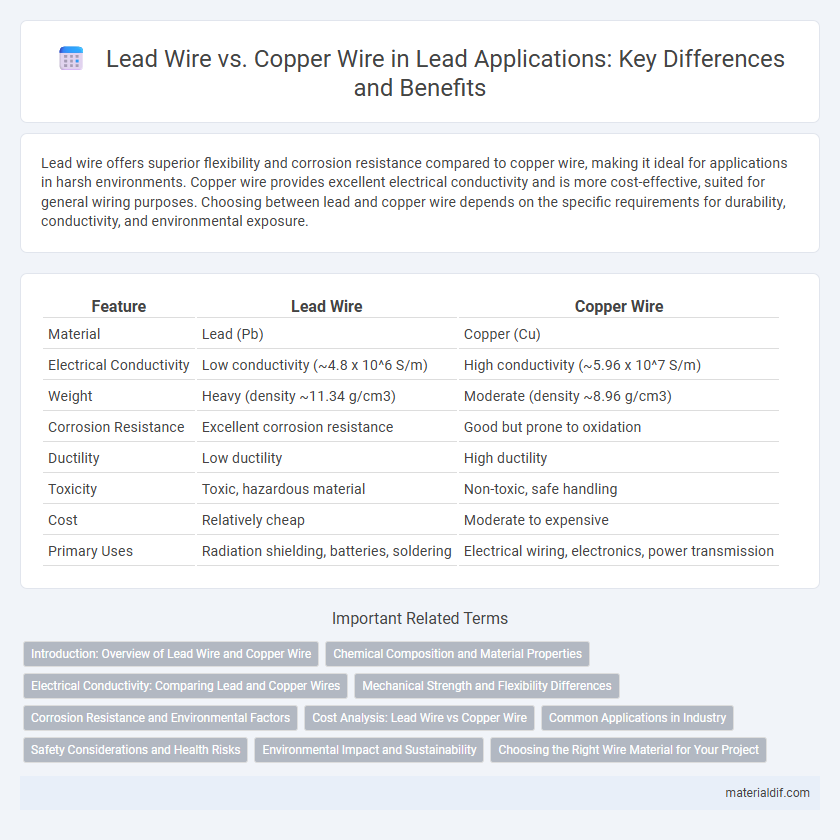

Lead wire offers superior flexibility and corrosion resistance compared to copper wire, making it ideal for applications in harsh environments. Copper wire provides excellent electrical conductivity and is more cost-effective, suited for general wiring purposes. Choosing between lead and copper wire depends on the specific requirements for durability, conductivity, and environmental exposure.

Table of Comparison

| Feature | Lead Wire | Copper Wire |

|---|---|---|

| Material | Lead (Pb) | Copper (Cu) |

| Electrical Conductivity | Low conductivity (~4.8 x 10^6 S/m) | High conductivity (~5.96 x 10^7 S/m) |

| Weight | Heavy (density ~11.34 g/cm3) | Moderate (density ~8.96 g/cm3) |

| Corrosion Resistance | Excellent corrosion resistance | Good but prone to oxidation |

| Ductility | Low ductility | High ductility |

| Toxicity | Toxic, hazardous material | Non-toxic, safe handling |

| Cost | Relatively cheap | Moderate to expensive |

| Primary Uses | Radiation shielding, batteries, soldering | Electrical wiring, electronics, power transmission |

Introduction: Overview of Lead Wire and Copper Wire

Lead wire exhibits excellent corrosion resistance and malleability, making it ideal for applications requiring flexibility and durability in harsh environments. Copper wire features superior electrical conductivity and thermal resistance, widely used in electrical wiring and electronic components. Both metals serve critical roles in industrial and electrical systems, with lead wire preferred for shielding and copper wire dominating power transmission.

Chemical Composition and Material Properties

Lead wire primarily consists of elemental lead (Pb), known for its high density, low melting point, and excellent corrosion resistance, making it ideal for applications requiring malleability and shielding against radiation. Copper wire, composed almost entirely of copper (Cu), exhibits superior electrical conductivity, high tensile strength, and excellent thermal conductivity, making it the preferred choice for electrical wiring and electronic components. The chemical stability of lead contrasts with the high conductivity and mechanical robustness of copper, influencing their distinct roles in electrical and industrial applications.

Electrical Conductivity: Comparing Lead and Copper Wires

Copper wire exhibits significantly higher electrical conductivity than lead wire, making it the preferred choice for efficient electrical transmission. The electrical conductivity of copper is approximately 5.96 x 10^7 S/m, whereas lead's conductivity is much lower, around 4.8 x 10^6 S/m. This vast difference impacts energy loss and performance in electrical systems, favoring copper for most wiring applications.

Mechanical Strength and Flexibility Differences

Lead wire offers superior flexibility due to its low tensile strength and pliable nature, making it ideal for applications requiring frequent bending. Copper wire, in contrast, has higher mechanical strength, providing enhanced durability and resistance to stretching or breaking under stress. This distinction makes copper wire preferable for structural electrical installations, while lead wire suits dynamic or low-stress environments.

Corrosion Resistance and Environmental Factors

Lead wire exhibits superior corrosion resistance compared to copper wire, especially in acidic or saline environments where copper tends to oxidize and degrade over time. The dense, inert nature of lead creates a protective barrier that significantly reduces the impact of environmental factors such as moisture and chemical exposure. In applications requiring long-term durability under harsh conditions, lead wire offers enhanced reliability due to its resistance to corrosion-related failures.

Cost Analysis: Lead Wire vs Copper Wire

Lead wire generally costs less than copper wire due to its lower market price and abundance, making it a budget-friendly option for certain applications. Copper wire, while more expensive, offers superior electrical conductivity and durability, which can reduce long-term maintenance and replacement costs. Evaluating total ownership cost is crucial, as initial savings with lead wire may be offset by higher energy losses and shorter lifespan compared to copper wire.

Common Applications in Industry

Lead wire is primarily used in radiation shielding and battery manufacturing due to its high density and corrosion resistance, making it ideal for applications requiring protection from radiation and chemical stability. Copper wire dominates electrical wiring and electronics industries because of its excellent electrical conductivity and ductility, enabling efficient power transmission and flexible circuit connections. Industries such as telecommunications, power distribution, and automotive manufacturing rely heavily on copper wire for its superior conductive properties, whereas lead wire finds niche uses where durability and shielding are critical.

Safety Considerations and Health Risks

Lead wire poses significant health risks due to lead's toxic properties, which can cause neurological damage and other serious health issues upon prolonged exposure or inhalation of lead dust or fumes. Copper wire is generally safer, with fewer health hazards, but can still cause allergic reactions or skin irritation in sensitive individuals. Proper handling, use of protective gear, and compliance with safety regulations are essential when working with lead wire to mitigate lead poisoning risks.

Environmental Impact and Sustainability

Lead wire poses significant environmental risks due to its toxicity and potential for soil and water contamination during disposal or corrosion, making it less sustainable. Copper wire, while requiring energy-intensive mining, is more environmentally friendly because it is highly recyclable and has a lower toxicity profile. Sustainable practices prioritize copper wire recycling to reduce resource extraction and environmental damage compared to lead wire usage.

Choosing the Right Wire Material for Your Project

Lead wire offers superior resistance to corrosion and flexibility, making it ideal for applications requiring durability in harsh environments. Copper wire excels in electrical conductivity and thermal performance, ensuring efficient energy transfer and minimal signal loss. Selecting the right wire material depends on project-specific needs such as electrical requirements, environmental exposure, and mechanical stress.

Lead wire vs Copper wire Infographic

materialdif.com

materialdif.com