Lead wool offers superior flexibility and is ideal for filling gaps or creating custom shapes in radiation shielding applications, while lead tape provides a convenient adhesive backing for quick, flat surface coverage. Lead tape is easier to apply on smooth surfaces and is commonly used for patching or sealing, whereas lead wool can conform to irregular contours and is preferred for complex or uneven areas. Both materials provide effective UV and radiation protection, but the choice depends on the specific requirements of malleability and ease of installation.

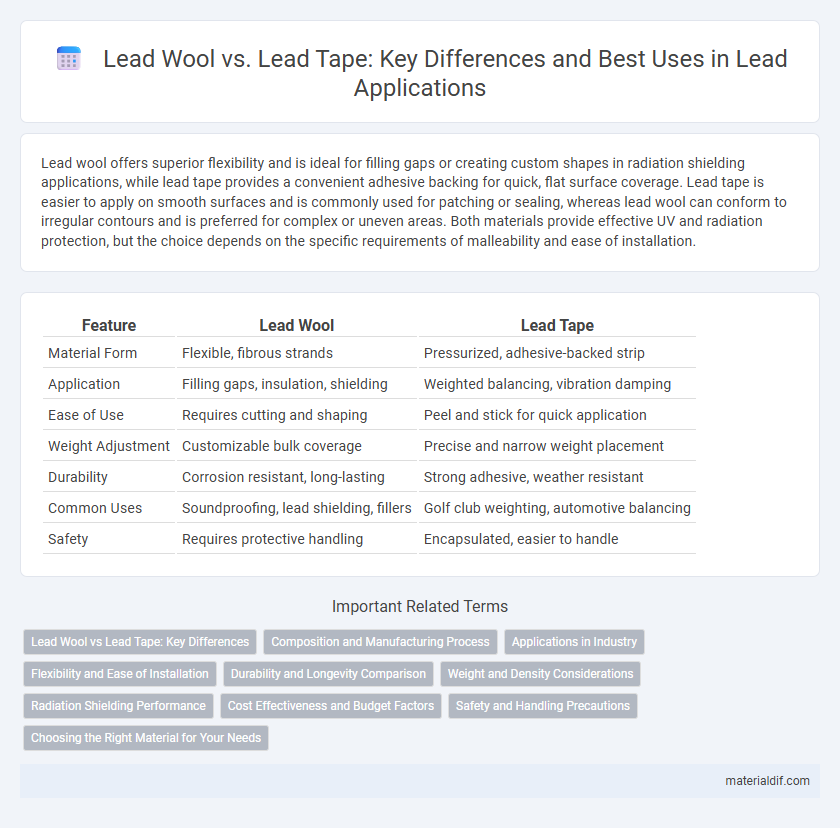

Table of Comparison

| Feature | Lead Wool | Lead Tape |

|---|---|---|

| Material Form | Flexible, fibrous strands | Pressurized, adhesive-backed strip |

| Application | Filling gaps, insulation, shielding | Weighted balancing, vibration damping |

| Ease of Use | Requires cutting and shaping | Peel and stick for quick application |

| Weight Adjustment | Customizable bulk coverage | Precise and narrow weight placement |

| Durability | Corrosion resistant, long-lasting | Strong adhesive, weather resistant |

| Common Uses | Soundproofing, lead shielding, fillers | Golf club weighting, automotive balancing |

| Safety | Requires protective handling | Encapsulated, easier to handle |

Lead Wool vs Lead Tape: Key Differences

Lead wool consists of fine, flexible fibers ideal for filling small gaps and providing airtight seals in plumbing and construction applications, while lead tape is a dense, adhesive-backed strip used primarily for weight distribution and vibration dampening in fishing, sports equipment, and automotive repairs. Lead wool offers superior conformability to irregular surfaces and can be compacted to create tight seals, whereas lead tape is favored for its ease of application and removable properties without damaging surfaces. The choice between lead wool and lead tape depends on the specific need for sealing precision versus simple weight or vibration management.

Composition and Manufacturing Process

Lead wool consists of thin, flexible strands of pure lead wire, produced by drawing molten lead through fine dies and then mechanically separating it into fibrous strands. Lead tape is created by rolling molten lead into flat, thin sheets that are subsequently cut into narrow strips, often reinforced with adhesive backing for easier application. Both materials utilize high-purity lead but differ significantly in form, manufacturing techniques, and intended applications.

Applications in Industry

Lead wool excels in applications requiring flexible insulation in electrical and plumbing industries due to its malleability and resistance to corrosion. Lead tape is preferred in radiation shielding and soundproofing within medical and construction sectors for its ease of application and uniform coverage. Both materials provide essential solutions in industrial sealing, vibration damping, and protective layering.

Flexibility and Ease of Installation

Lead wool offers superior flexibility, making it ideal for filling irregular gaps and hard-to-reach areas where precise conformity is required. Lead tape provides a more straightforward installation process, as its adhesive backing allows for quick application on smooth, flat surfaces without additional tools. Choosing between the two depends on the specific project needs, with lead wool excelling in adaptability and lead tape delivering convenience and speed.

Durability and Longevity Comparison

Lead wool offers superior durability due to its flexible, malleable structure that resists cracking and corrosion over time, making it ideal for long-term sealing applications. Lead tape, while convenient and easy to apply, tends to degrade faster under environmental stress, exhibiting peeling and brittleness after prolonged exposure. Selecting lead wool enhances longevity and maintains a reliable seal in harsh conditions compared to the shorter lifespan of lead tape.

Weight and Density Considerations

Lead wool offers higher density and weight per volume compared to lead tape, making it ideal for applications requiring maximum mass in confined spaces. Its malleable, fibrous structure allows it to conform to irregular shapes, enhancing uniformity of weight distribution. Lead tape, while denser per unit length, is thinner and less adaptable, making it preferable for precision-weight adjustments where surface layering is needed.

Radiation Shielding Performance

Lead wool offers superior radiation shielding performance compared to lead tape due to its flexible, interwoven fibers that create a more uniform barrier against ionizing radiation. The density and thickness of lead wool contribute to its effectiveness in attenuating gamma rays and X-rays, making it ideal for medical and industrial applications requiring precise radiation protection. In contrast, lead tape, though convenient for smaller or irregular surfaces, provides less consistent shielding and is better suited for supplementary or minor radiation protection tasks.

Cost Effectiveness and Budget Factors

Lead wool generally offers higher cost-effectiveness for projects requiring flexible shaping and filling small gaps due to its malleability and lower price per volume. Lead tape, while more expensive upfront, provides precise application and reduced waste, making it budget-friendly for targeted soundproofing or vibration damping tasks. Selecting between lead wool and lead tape depends on project scale, material waste tolerance, and specific installation requirements influencing overall budget efficiency.

Safety and Handling Precautions

Lead wool requires careful handling with protective gloves and masks due to its fine particles, which pose inhalation and skin absorption risks. Lead tape, being solid and adhesive, reduces direct contact but still demands careful disposal to avoid environmental contamination. Both materials necessitate strict adherence to regulatory guidelines to minimize lead exposure and ensure safe usage.

Choosing the Right Material for Your Needs

Lead wool provides flexibility and easy application for filling gaps, making it ideal for intricate or irregular surfaces, while lead tape offers a convenient, adhesive-backed solution for precise weight adjustments on golf clubs, fishing rods, or bike frames. Consider lead wool when insulating or sealing is required, as its malleable strands conform well to uneven spaces, whereas lead tape suits situations demanding quick, clean application with uniform thickness. Selecting the right material depends on the specific use case, surface contours, and the desired permanence of the lead application.

Lead Wool vs Lead Tape Infographic

materialdif.com

materialdif.com