White lead, primarily used in paint and cosmetics, offers superior opacity and a smooth finish but poses significant toxicity risks due to its high lead content. Red lead, known for its corrosion resistance, is commonly applied as a protective coating on metals, especially in industrial settings, providing durability without compromising structural integrity. Understanding the distinct applications and health hazards of white lead and red lead is crucial for safe handling and effective use in various industries.

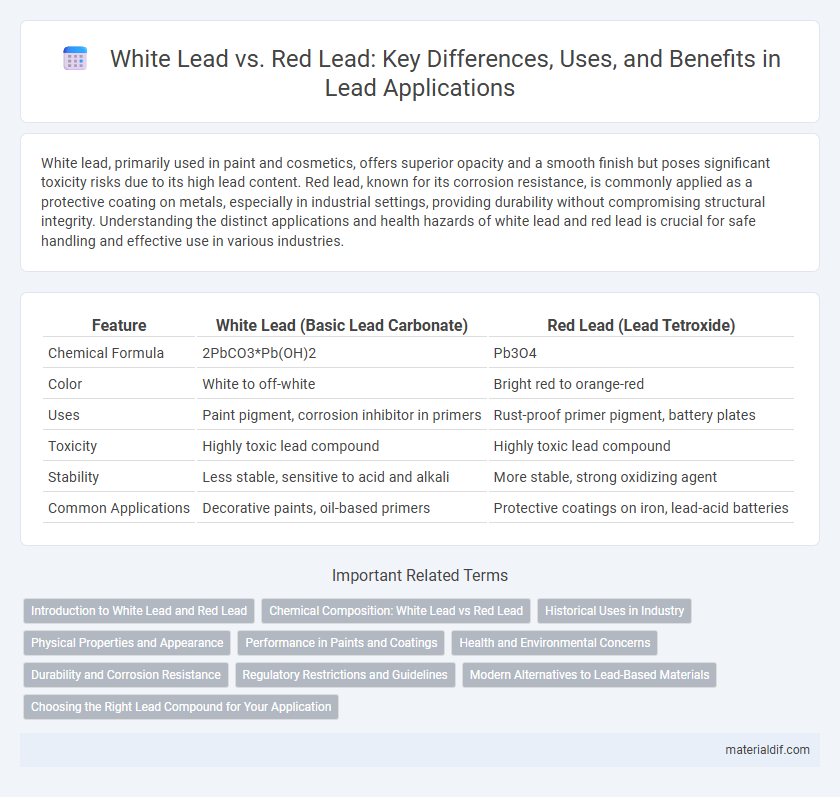

Table of Comparison

| Feature | White Lead (Basic Lead Carbonate) | Red Lead (Lead Tetroxide) |

|---|---|---|

| Chemical Formula | 2PbCO3*Pb(OH)2 | Pb3O4 |

| Color | White to off-white | Bright red to orange-red |

| Uses | Paint pigment, corrosion inhibitor in primers | Rust-proof primer pigment, battery plates |

| Toxicity | Highly toxic lead compound | Highly toxic lead compound |

| Stability | Less stable, sensitive to acid and alkali | More stable, strong oxidizing agent |

| Common Applications | Decorative paints, oil-based primers | Protective coatings on iron, lead-acid batteries |

Introduction to White Lead and Red Lead

White lead, primarily composed of basic lead carbonate, serves as an essential pigment in paints due to its excellent opacity and durability. Red lead, or lead tetroxide, is widely used as a corrosion-resistant primer in metal protection, offering superior adhesion and rust prevention. Both compounds highlight lead's versatility in industrial applications, balancing pigmentation properties and protective capabilities.

Chemical Composition: White Lead vs Red Lead

White lead, chemically known as basic lead carbonate (2PbCO3*Pb(OH)2), consists of a mixture of lead carbonate and lead hydroxide, presenting a pale, almost white coloration. Red lead, or lead tetroxide (Pb3O4), is a bright red-orange compound composed of both lead(II) oxide (PbO) and lead(IV) oxide (PbO2) in a mixed oxidation state. The distinct chemical compositions influence their applications, with white lead commonly used as a pigment and in corrosion protection, while red lead serves predominantly as a rust-inhibitive primer and oxidizing agent.

Historical Uses in Industry

White lead, primarily composed of basic lead carbonate, was extensively used in the paint industry from the Roman era through the 20th century due to its excellent opacity and adhesion properties. Red lead, or lead tetroxide, found significant application as a protective pigment against corrosion in metal primers and marine coatings, especially in industrial and maritime settings during the 19th and early 20th centuries. Both compounds played crucial roles in industrial advancements despite their toxicity, influencing regulations in occupational health and environmental safety.

Physical Properties and Appearance

White lead, chemically known as basic lead carbonate, appears as a soft, white powder with low solubility in water and a density of about 6.5 g/cm3, while red lead, or lead tetroxide, shows a bright red to orange hue with a higher density of approximately 8.3 g/cm3 and a more crystalline structure. White lead has a dull, matte finish ideal for use in traditional paints due to its excellent covering power, whereas red lead exhibits a glossy, vivid appearance commonly used as an anti-corrosive primer in industrial applications. The difference in color and physical density between white lead and red lead reflects their distinct molecular compositions and crystal lattice arrangements, influencing their specific uses.

Performance in Paints and Coatings

White lead, primarily basic lead carbonate, offers excellent opacity and durability in paints, providing superior corrosion resistance and a smooth, attractive finish. Red lead, composed of lead tetroxide, excels in anti-corrosive performance on metal surfaces, particularly in industrial coatings, due to its strong rust-inhibiting properties. Both play crucial roles in protective coatings, but white lead is preferred for aesthetic finishes, while red lead is favored for heavy-duty corrosion protection.

Health and Environmental Concerns

White lead (basic lead carbonate) poses significant health risks due to its high toxicity and potential to cause lead poisoning, affecting neurological and developmental functions. Red lead (lead tetroxide) also presents health hazards, especially in industrial exposure, but is less commonly absorbed through skin contact compared to white lead. Both compounds contribute to environmental contamination, with white lead more prone to leaching into soil and water, necessitating strict handling and disposal regulations to minimize ecological impact.

Durability and Corrosion Resistance

White lead, primarily composed of basic lead carbonate, offers moderate durability but is more susceptible to corrosion when exposed to moisture and acidic environments. Red lead, or lead tetroxide, demonstrates superior corrosion resistance and enhanced durability, especially in harsh industrial conditions, making it more suitable for protective coatings on metal surfaces. The denser oxide layer in red lead effectively prevents oxidation, thereby extending the lifespan of treated structures compared to white lead.

Regulatory Restrictions and Guidelines

White lead, primarily composed of basic lead carbonate, faces stringent regulatory restrictions due to its high toxicity and risk of lead poisoning, especially in residential paint applications, leading to widespread bans in many countries such as the United States and the European Union. Red lead, or lead tetroxide, is similarly regulated but is often permitted in limited industrial uses such as corrosion-resistant primers and battery manufacturing, subject to strict safety guidelines and environmental controls. Both forms are monitored under frameworks like the Toxic Substances Control Act (TSCA) and REACH regulations, which enforce limitations on production, usage, and disposal to minimize occupational and environmental lead exposure.

Modern Alternatives to Lead-Based Materials

Modern alternatives to white lead and red lead pigments focus on non-toxic, environmentally friendly compounds like titanium dioxide and iron oxide, which provide similar opacity and color durability without the harmful effects of lead. These substitutes are widely used in contemporary paints and coatings, ensuring safe indoor air quality and compliance with stringent environmental regulations. Advancements in polymer-based and nano-engineered pigments further enhance performance, making lead-free materials the preferred choice in construction and artistic applications.

Choosing the Right Lead Compound for Your Application

White lead, primarily basic lead carbonate, offers excellent corrosion resistance and a smooth finish, making it ideal for use in primers and paints; red lead, or lead tetroxide, provides superior rust-proofing and high-temperature stability, suited for industrial coatings and batteries. Selecting the appropriate lead compound depends on factors such as durability requirements, environmental exposure, and chemical compatibility with substrates. Understanding the specific properties of white lead versus red lead ensures optimal performance and longevity in applications ranging from protective coatings to electrochemical devices.

White lead vs Red lead Infographic

materialdif.com

materialdif.com