Lead alloys offer enhanced mechanical strength and improved corrosion resistance compared to pure lead, making them more suitable for demanding industrial applications. Pure lead provides excellent malleability and excellent radiation shielding capabilities but lacks the durability required for some structural uses. Selecting between lead alloys and pure lead depends on balancing factors such as strength, corrosion resistance, and specific application needs.

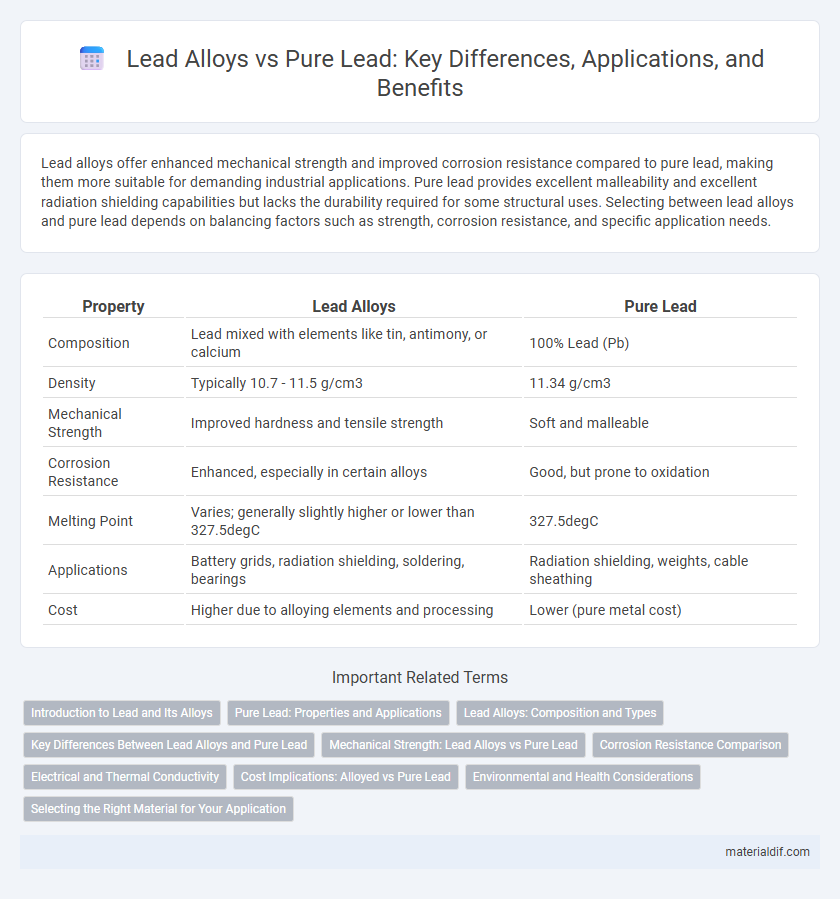

Table of Comparison

| Property | Lead Alloys | Pure Lead |

|---|---|---|

| Composition | Lead mixed with elements like tin, antimony, or calcium | 100% Lead (Pb) |

| Density | Typically 10.7 - 11.5 g/cm3 | 11.34 g/cm3 |

| Mechanical Strength | Improved hardness and tensile strength | Soft and malleable |

| Corrosion Resistance | Enhanced, especially in certain alloys | Good, but prone to oxidation |

| Melting Point | Varies; generally slightly higher or lower than 327.5degC | 327.5degC |

| Applications | Battery grids, radiation shielding, soldering, bearings | Radiation shielding, weights, cable sheathing |

| Cost | Higher due to alloying elements and processing | Lower (pure metal cost) |

Introduction to Lead and Its Alloys

Lead alloys exhibit enhanced mechanical properties and corrosion resistance compared to pure lead, making them essential in various industrial applications. Common lead alloys include lead-antimony, lead-tin, and lead-calcium, each offering specific advantages such as increased hardness, improved casting qualities, and better fatigue resistance. These alloys balance the softness and malleability of pure lead with added strength, broadening their usability in batteries, radiation shielding, and soldering materials.

Pure Lead: Properties and Applications

Pure lead exhibits superior corrosion resistance and excellent malleability compared to lead alloys, making it ideal for applications in radiation shielding and batteries. Its low melting point and high density enable efficient casting and soundproofing performance in construction and industrial use. Despite being softer than lead alloys, pure lead's chemical inertness ensures longevity in plumbing and protective coatings.

Lead Alloys: Composition and Types

Lead alloys consist primarily of lead combined with elements such as antimony, tin, and copper, enhancing properties like hardness, strength, and corrosion resistance. Common types include lead-antimony alloys used in battery grids, lead-tin alloys employed in soldering, and lead-copper alloys for improved wear resistance in bearings. These compositions optimize performance for industrial applications compared to pure lead's softness and limited mechanical strength.

Key Differences Between Lead Alloys and Pure Lead

Lead alloys exhibit enhanced mechanical strength, corrosion resistance, and thermal stability compared to pure lead, which is relatively soft and prone to oxidation. Key differences include the presence of metals such as antimony, tin, or copper in lead alloys, which improve hardness and durability, making them suitable for applications like batteries and radiation shielding. Pure lead's high density and malleability make it ideal for uses requiring easier shaping but less structural integrity.

Mechanical Strength: Lead Alloys vs Pure Lead

Lead alloys exhibit significantly higher mechanical strength compared to pure lead due to the addition of elements like antimony, tin, and calcium, which enhance hardness and durability. Pure lead has a low tensile strength and is prone to deformation under stress, limiting its use in structural applications. The mechanical improvements in lead alloys make them ideal for use in batteries, radiation shielding, and corrosion-resistant materials where enhanced strength is critical.

Corrosion Resistance Comparison

Lead alloys exhibit enhanced corrosion resistance compared to pure lead due to the addition of elements such as antimony, tin, or calcium, which create a more stable and protective oxide layer on the surface. Pure lead, while naturally corrosion-resistant in many environments, is more susceptible to localized corrosion and pitting in acidic or chloride-rich conditions. The improved durability of lead alloys makes them preferable in applications requiring long-term exposure to harsh environments, such as marine and industrial settings.

Electrical and Thermal Conductivity

Lead alloys exhibit lower electrical and thermal conductivity compared to pure lead due to the presence of alloying elements that disrupt the atomic lattice and impede electron and phonon flow. Pure lead has a thermal conductivity of approximately 35.3 W/m*K and electrical conductivity around 4.8 x 10^6 S/m, making it more efficient for applications requiring high conductivity. Alloys such as lead-tin or lead-antimony typically reduce conductivity values by 10-20%, impacting their suitability in electrical and thermal management contexts.

Cost Implications: Alloyed vs Pure Lead

Lead alloys often present cost advantages over pure lead by enhancing mechanical properties and reducing material volume needed for specific applications, which lowers overall expenses. Alloying elements such as antimony or tin improve hardness and durability, decreasing maintenance and replacement costs compared to pure lead. Despite a higher initial alloy cost, long-term savings arise from improved performance and extended lifespan in industries like battery manufacturing and radiation shielding.

Environmental and Health Considerations

Lead alloys typically contain metals such as antimony, tin, or arsenic, which can alter toxicity levels compared to pure lead. Environmental risks from lead alloys persist due to potential heavy metal leaching, posing contamination threats to soil and water. Health considerations emphasize minimizing exposure to both pure lead and its alloys, as they release harmful lead particles that can cause neurological and renal damage.

Selecting the Right Material for Your Application

Lead alloys offer enhanced mechanical properties, such as increased strength and corrosion resistance, compared to pure lead, making them ideal for applications requiring durability and longevity. Pure lead provides excellent malleability and high density, suitable for shielding and vibration damping where softness and weight are critical. Selecting the right material depends on application-specific demands like wear resistance, conductivity, and environmental exposure to ensure optimal performance and cost-efficiency.

Lead Alloys vs Pure Lead Infographic

materialdif.com

materialdif.com