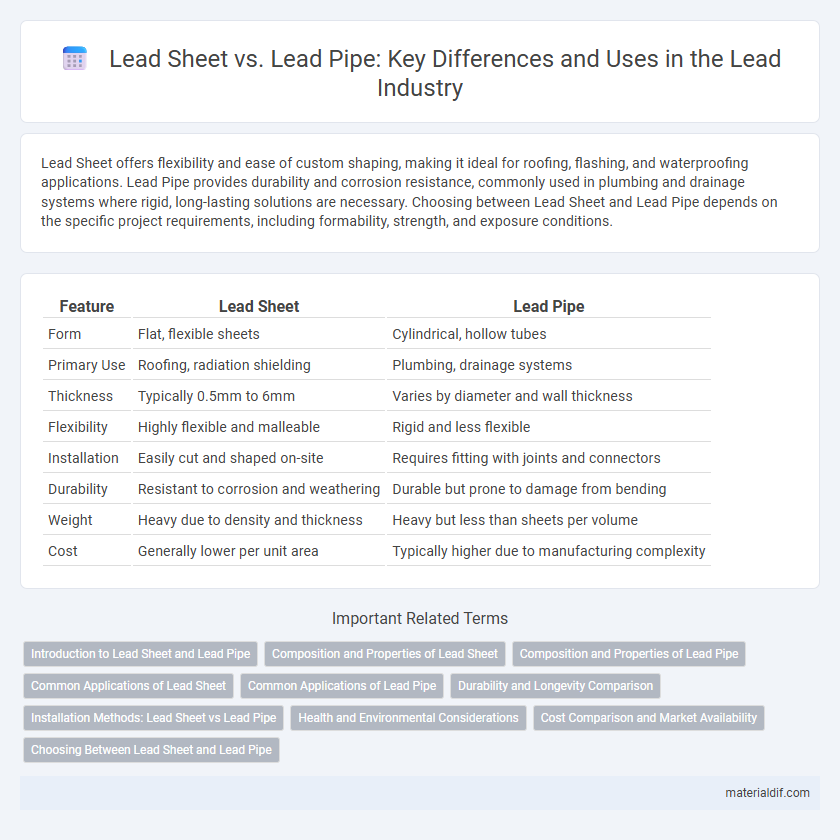

Lead Sheet offers flexibility and ease of custom shaping, making it ideal for roofing, flashing, and waterproofing applications. Lead Pipe provides durability and corrosion resistance, commonly used in plumbing and drainage systems where rigid, long-lasting solutions are necessary. Choosing between Lead Sheet and Lead Pipe depends on the specific project requirements, including formability, strength, and exposure conditions.

Table of Comparison

| Feature | Lead Sheet | Lead Pipe |

|---|---|---|

| Form | Flat, flexible sheets | Cylindrical, hollow tubes |

| Primary Use | Roofing, radiation shielding | Plumbing, drainage systems |

| Thickness | Typically 0.5mm to 6mm | Varies by diameter and wall thickness |

| Flexibility | Highly flexible and malleable | Rigid and less flexible |

| Installation | Easily cut and shaped on-site | Requires fitting with joints and connectors |

| Durability | Resistant to corrosion and weathering | Durable but prone to damage from bending |

| Weight | Heavy due to density and thickness | Heavy but less than sheets per volume |

| Cost | Generally lower per unit area | Typically higher due to manufacturing complexity |

Introduction to Lead Sheet and Lead Pipe

Lead sheets are thin, flexible slabs of lead metal commonly used for roofing, radiation shielding, and soundproofing due to their excellent malleability and corrosion resistance. Lead pipes, traditionally employed in plumbing systems, consist of rigid or semi-rigid cylindrical tubes that allow fluid transport but are largely phased out because of lead's toxicity risks. Understanding the properties, applications, and safety concerns distinguishes lead sheets from lead pipes in industrial and construction contexts.

Composition and Properties of Lead Sheet

Lead sheets are composed primarily of pure lead with a high density of 11.34 g/cm3, offering excellent corrosion resistance and malleability. Unlike lead pipes, which are typically cast or extruded for fluid transport, lead sheets are rolled into thin, flexible layers ideal for waterproofing, radiation shielding, and chemical protection. Their soft, ductile nature allows easy shaping without cracking, making lead sheets suitable for various industrial and construction applications.

Composition and Properties of Lead Pipe

Lead pipe is composed primarily of pure lead or lead alloys, offering high corrosion resistance and malleability compared to lead sheets that are flat and used mainly for roofing or flashing. The properties of lead pipe include excellent durability and flexibility, making it suitable for plumbing and shielding applications, while lead sheets are often harder and less flexible due to their thin, flat shape. Lead pipes typically have a uniform cylindrical structure providing superior flow control and chemical stability in fluid transport systems.

Common Applications of Lead Sheet

Lead sheet is widely used in construction for roofing, waterproofing, and radiation shielding due to its malleability and corrosion resistance. It also serves as a protective barrier in electrical cables and soundproofing materials. Unlike lead pipe, which primarily transports fluids, lead sheet's versatility is essential in architectural flashing and industrial sealing applications.

Common Applications of Lead Pipe

Lead pipe is commonly used in plumbing systems for water supply and wastewater drainage due to its malleability and resistance to corrosion. Unlike lead sheets, which are primarily utilized in roofing, flashing, and soundproofing, lead pipes are favored for their durability in conveying fluids. Despite concerns about lead contamination, lead pipes remain prevalent in historic building restoration and specific industrial applications.

Durability and Longevity Comparison

Lead sheets exhibit superior durability compared to lead pipes due to their uniform thickness and resistance to corrosion, making them ideal for roofing and waterproofing applications. Lead pipes, while historically used for plumbing, tend to degrade faster under water exposure, leading to leaks and contamination risks over time. The longevity of lead sheets often exceeds decades with minimal maintenance, whereas lead pipes typically require replacement or frequent repairs within 20 to 30 years.

Installation Methods: Lead Sheet vs Lead Pipe

Lead sheets are typically installed by overlapping and soldering or using mechanical fasteners to create waterproof seals, commonly applied in roofing, flashing, and cladding. Lead pipes require precise cutting, fitting with compression or push-fit joints, and sometimes soldering or welding for secure plumbing connections. Installation of lead sheets emphasizes flexibility and surface coverage, while lead pipe installation focuses on airtight and pressure-resistant joints.

Health and Environmental Considerations

Lead sheets and lead pipes both pose significant health risks due to lead's toxicity, which can cause neurological damage and developmental issues with prolonged exposure. Lead pipes often contribute to water contamination through corrosion, increasing the risk of lead poisoning in drinking water supplies, whereas lead sheets primarily pose hazards through dust and particulate inhalation during handling or deterioration. Environmentally, both materials are persistently toxic and can bioaccumulate, requiring proper disposal and replacement with safer alternatives to mitigate soil and water pollution.

Cost Comparison and Market Availability

Lead sheets generally cost less per square foot compared to lead pipes, making them a more economical choice for applications requiring coverage or shielding. Lead pipes, however, have variable pricing influenced by diameter, wall thickness, and demand, often leading to higher costs in specialized plumbing or radiation protection uses. Market availability favors lead sheets due to broader industrial applications and larger production volumes, while lead pipes are less commonly stocked and may require custom orders depending on regional suppliers.

Choosing Between Lead Sheet and Lead Pipe

Choosing between lead sheet and lead pipe depends on the specific application requirements such as flexibility, thickness, and form factor. Lead sheets offer versatility for roofing, flashing, and radiation shielding with customizable thickness typically ranging from 0.35mm to 30mm. Lead pipes provide durable, corrosion-resistant tubing ideal for plumbing, industrial, and protective uses, available in various diameters and wall thicknesses to meet precise fluid or gas transportation needs.

Lead Sheet vs Lead Pipe Infographic

materialdif.com

materialdif.com