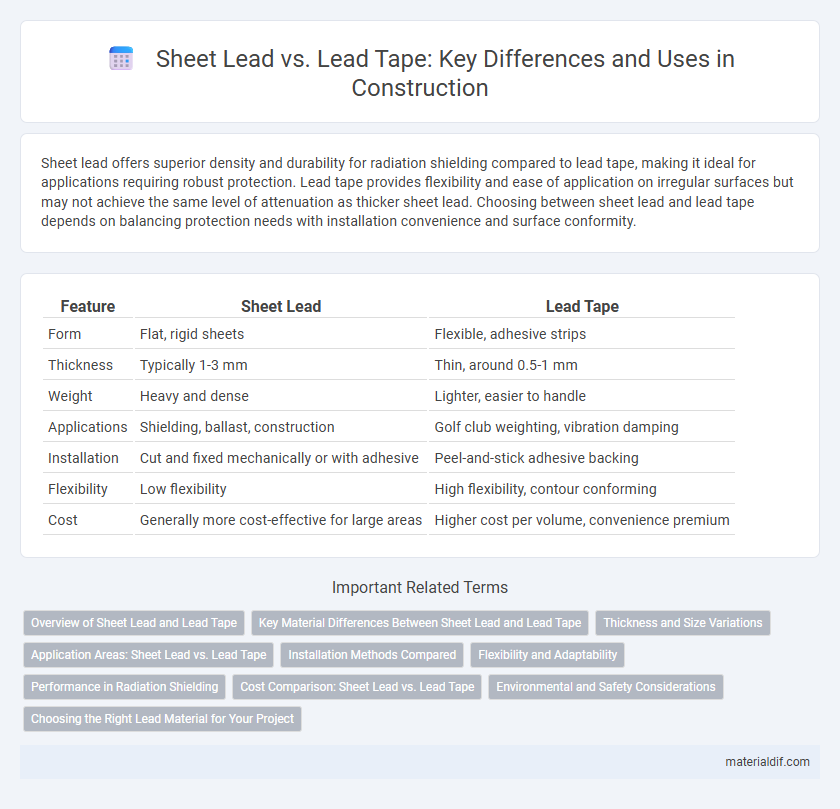

Sheet lead offers superior density and durability for radiation shielding compared to lead tape, making it ideal for applications requiring robust protection. Lead tape provides flexibility and ease of application on irregular surfaces but may not achieve the same level of attenuation as thicker sheet lead. Choosing between sheet lead and lead tape depends on balancing protection needs with installation convenience and surface conformity.

Table of Comparison

| Feature | Sheet Lead | Lead Tape |

|---|---|---|

| Form | Flat, rigid sheets | Flexible, adhesive strips |

| Thickness | Typically 1-3 mm | Thin, around 0.5-1 mm |

| Weight | Heavy and dense | Lighter, easier to handle |

| Applications | Shielding, ballast, construction | Golf club weighting, vibration damping |

| Installation | Cut and fixed mechanically or with adhesive | Peel-and-stick adhesive backing |

| Flexibility | Low flexibility | High flexibility, contour conforming |

| Cost | Generally more cost-effective for large areas | Higher cost per volume, convenience premium |

Overview of Sheet Lead and Lead Tape

Sheet lead and lead tape are both versatile materials used for radiation shielding and soundproofing in medical, construction, and industrial applications. Sheet lead offers uniform thickness and durability, providing robust protection in walls and barriers, while lead tape is flexible and adhesive, ideal for sealing seams, joints, and irregular surfaces. Both materials are effective in minimizing radiation exposure but differ in form factor and application versatility.

Key Material Differences Between Sheet Lead and Lead Tape

Sheet lead is a dense, malleable material typically available in thicker, rigid forms ranging from 1mm to 10mm, ideal for shielding applications requiring substantial weight and protection against radiation or sound. Lead tape, thinner and more flexible at around 0.3mm to 1mm thickness, offers enhanced conformability on irregular surfaces, making it suitable for sealing, vibration damping, or minor shielding tasks. The primary material difference lies in thickness and flexibility, with sheet lead providing robust durability and lead tape offering adaptability for precise placement and ease of use in confined or curved spaces.

Thickness and Size Variations

Sheet lead offers uniform thickness typically ranging from 0.5mm to 3mm and is available in large standard sizes such as 4ft by 8ft sheets, allowing for easy cutting and shaping. Lead tape is much thinner, usually between 0.3mm and 0.8mm thick, and comes in narrow rolls or strips with widths varying from 6mm to 50mm, making it ideal for precise weighting and balancing tasks. The size variations in sheet lead accommodate structural applications, while the thin, flexible nature of lead tape suits delicate or contoured surfaces requiring fine thickness control.

Application Areas: Sheet Lead vs. Lead Tape

Sheet lead is widely used in construction and radiation shielding for its uniform thickness and reliable density, ideal for applications such as roofing, cladding, and medical imaging facilities. Lead tape, valued for its flexibility and adhesive backing, is preferred in sealing joints, repairing lead sheets, and customizing shielding in confined spaces. Both materials serve critical roles in nuclear power plants, X-ray rooms, and soundproofing solutions, with the choice dependent on installation precision and surface conformity requirements.

Installation Methods Compared

Sheet lead installation involves cutting and shaping rigid, flat sheets to fit surfaces, providing a durable and weather-resistant barrier, ideal for roof flashing and window detailing. Lead tape offers a flexible, adhesive-backed solution that easily conforms to complex angles and tight spaces, enabling quicker application and reducing the need for mechanical fasteners. Both methods require skillful handling to ensure proper overlap and sealing, but lead tape is often preferred for retrofit projects due to its ease of use and minimal preparation.

Flexibility and Adaptability

Sheet lead offers superior flexibility and can be easily cut or molded to fit complex shapes, making it ideal for custom applications in radiation shielding. Lead tape provides adaptability for quick, on-the-go adjustments and sealing small gaps but lacks the durability and malleability of sheet lead. Both materials complement each other in environments requiring adaptable yet robust lead protection solutions.

Performance in Radiation Shielding

Sheet lead offers superior radiation shielding performance due to its uniform density and thickness, effectively attenuating gamma rays and X-rays in medical and industrial applications. Lead tape, while more flexible and easier to apply on irregular surfaces, typically provides less consistent coverage and may require overlapping layers to match the shielding effectiveness of sheet lead. The choice between sheet lead and lead tape depends on the specific shielding requirements, with sheet lead preferred for high-performance protection and lead tape suited for customizable, lower-intensity radiation barriers.

Cost Comparison: Sheet Lead vs. Lead Tape

Sheet lead generally offers a lower cost per square foot compared to lead tape, making it more economical for larger projects requiring extensive coverage. Lead tape, while more expensive on a per-foot basis, provides flexibility and ease of installation for smaller or irregularly shaped areas. The cost efficiency of sheet lead increases with project scale, whereas lead tape reduces labor costs in precision applications.

Environmental and Safety Considerations

Sheet lead offers robust environmental protection due to its thickness, providing effective shielding against radiation and chemical exposure in industrial settings, yet its weight raises concerns for worker safety during handling. Lead tape, being thinner and more flexible, minimizes physical strain and reduces the risk of musculoskeletal injuries, making it safer for frequent application, but may offer less comprehensive environmental protection. Proper disposal and use of protective equipment are crucial for both forms, as lead's toxicity presents significant environmental and health hazards if mishandled.

Choosing the Right Lead Material for Your Project

Sheet lead offers excellent durability and malleability, making it ideal for roofing, flashing, and waterproofing projects that require precise shaping and heavy-duty protection. Lead tape provides flexibility and ease of application, perfect for small-scale repairs, window glazing, and decorative purposes where thin, narrow strips are needed. Selecting between sheet lead and lead tape depends on the project's scale, required thickness, and ease of installation to ensure optimal performance and longevity.

Sheet lead vs Lead tape Infographic

materialdif.com

materialdif.com