Lead sheaths provide superior corrosion resistance in harsh environments, making them ideal for underground or marine cable protection. Aluminum sheaths offer a lightweight alternative with excellent mechanical strength and good corrosion resistance, suitable for overhead or less aggressive settings. Choosing between lead and aluminum sheaths depends on environmental exposure, weight considerations, and specific application requirements.

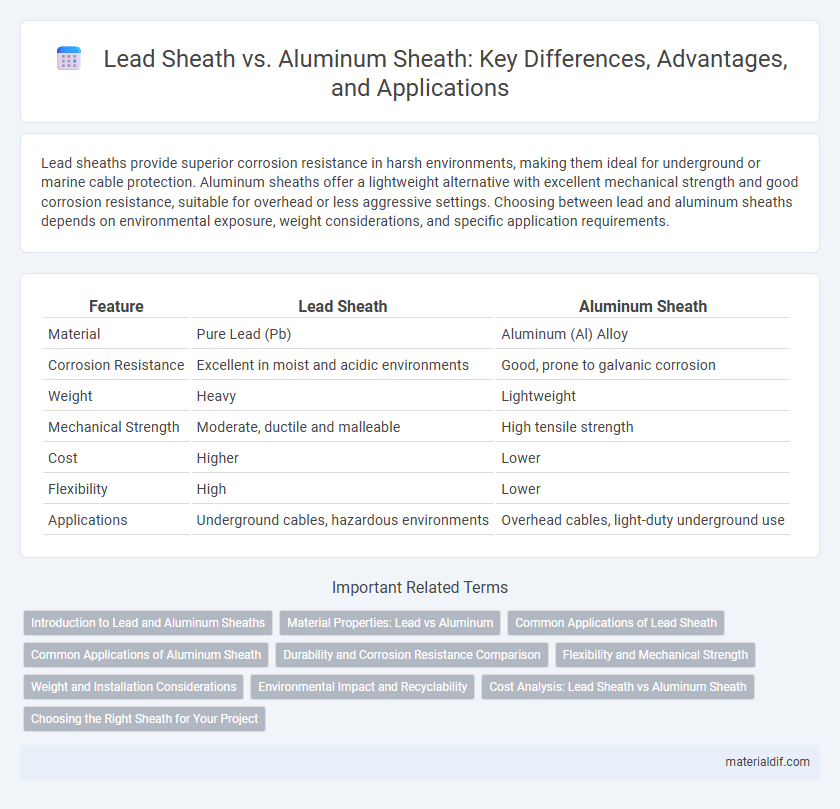

Table of Comparison

| Feature | Lead Sheath | Aluminum Sheath |

|---|---|---|

| Material | Pure Lead (Pb) | Aluminum (Al) Alloy |

| Corrosion Resistance | Excellent in moist and acidic environments | Good, prone to galvanic corrosion |

| Weight | Heavy | Lightweight |

| Mechanical Strength | Moderate, ductile and malleable | High tensile strength |

| Cost | Higher | Lower |

| Flexibility | High | Lower |

| Applications | Underground cables, hazardous environments | Overhead cables, light-duty underground use |

Introduction to Lead and Aluminum Sheaths

Lead sheath provides excellent corrosion resistance and flexibility, making it ideal for underground and marine cable protection. Aluminum sheath offers lightweight durability and superior thermal conductivity, often used in overhead and industrial power cables. Both sheaths serve as protective layers, enhancing cable longevity and mechanical strength.

Material Properties: Lead vs Aluminum

Lead sheaths provide superior corrosion resistance and excellent malleability, making them ideal for protecting cables in harsh environments. Aluminum sheaths, although lighter and more cost-effective, offer higher tensile strength and better heat dissipation but are more prone to corrosion if not properly treated. The choice between lead and aluminum sheaths depends on balancing durability, environmental resistance, and mechanical strength requirements.

Common Applications of Lead Sheath

Lead sheaths are commonly used in underground cables for power and telecommunication systems due to their excellent corrosion resistance and waterproofing properties. They provide robust protection against moisture and chemical exposure, making them ideal for marine and industrial environments. Aluminum sheaths, while lighter and more cost-effective, lack the superior durability and protective qualities that lead sheaths offer in harsh conditions.

Common Applications of Aluminum Sheath

Aluminum sheath cables are widely used in industrial and commercial electrical installations due to their excellent corrosion resistance and lightweight properties. They are commonly applied in underground power distribution, control cables for machinery, and instrumentation wiring where durability and environmental protection are crucial. Compared to lead sheaths, aluminum sheaths offer cost-effective solutions for medium to high voltage applications in harsh environments such as chemical plants and offshore platforms.

Durability and Corrosion Resistance Comparison

Lead sheaths exhibit superior corrosion resistance in aggressive environments due to their dense, impermeable nature, making them highly durable in underground and marine applications. Aluminum sheaths offer lighter weight and good corrosion resistance but are more prone to oxidation and mechanical damage over time. For long-term durability and protection against harsh chemical exposure, lead sheaths generally outperform aluminum sheaths.

Flexibility and Mechanical Strength

Lead sheaths offer superior flexibility due to their malleable nature, making them ideal for applications requiring frequent bending or movement. Aluminum sheaths provide higher mechanical strength and resistance to impact, ensuring better protection in harsh environments. While aluminum sheaths excel in durability, lead sheaths remain preferred for installations prioritizing ease of handling and adaptability.

Weight and Installation Considerations

Lead sheaths offer superior corrosion resistance but are significantly heavier than aluminum sheaths, impacting overall cable weight and handling. Aluminum sheaths reduce cable weight by up to 50%, facilitating easier installation and lowering labor costs in overhead and underground applications. Choosing between lead and aluminum sheaths depends on balancing the need for durability against the advantages of lighter weight and installation efficiency.

Environmental Impact and Recyclability

Lead sheath offers superior corrosion resistance but poses significant environmental risks due to its toxicity and difficulty in recycling processes. Aluminum sheath provides a more sustainable alternative with higher recyclability rates and lower ecological impact, making it preferable for eco-friendly applications. The environmental footprint of aluminum sheath manufacturing is also lower, contributing to its overall green credentials in cable protection.

Cost Analysis: Lead Sheath vs Aluminum Sheath

Lead sheath offers superior corrosion resistance but comes with higher material and installation costs compared to aluminum sheath, which is favored for its lightweight and cost-effectiveness in large-scale projects. The initial expense of lead sheathing is offset by its longevity and lower maintenance needs, while aluminum sheath, though less expensive upfront, may incur higher long-term costs due to potential corrosion and replacement. Budget allocation for cable protection must consider both upfront investment and lifecycle expenses to optimize overall project expenditure.

Choosing the Right Sheath for Your Project

Selecting the right sheath for your project requires understanding the key differences between lead and aluminum sheaths in cable protection. Lead sheaths offer superior corrosion resistance and flexibility, making them ideal for underground and marine cable installations with demanding environmental conditions. Aluminum sheaths provide a lightweight, cost-effective solution with excellent mechanical strength and thermal dissipation, suitable for overhead and indoor applications where weight savings are critical.

Lead sheath vs Aluminum sheath Infographic

materialdif.com

materialdif.com