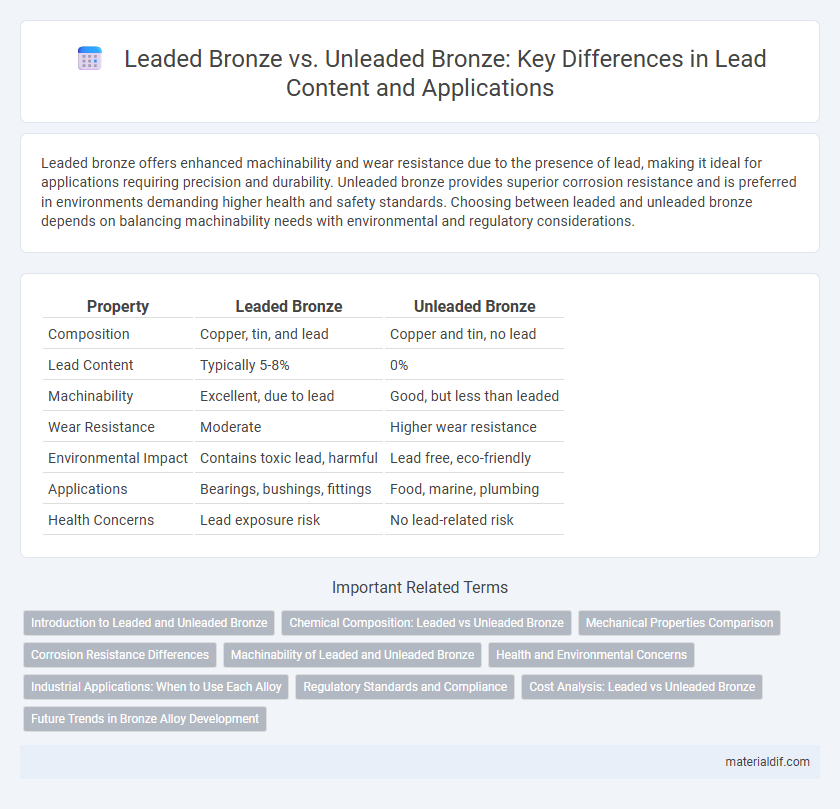

Leaded bronze offers enhanced machinability and wear resistance due to the presence of lead, making it ideal for applications requiring precision and durability. Unleaded bronze provides superior corrosion resistance and is preferred in environments demanding higher health and safety standards. Choosing between leaded and unleaded bronze depends on balancing machinability needs with environmental and regulatory considerations.

Table of Comparison

| Property | Leaded Bronze | Unleaded Bronze |

|---|---|---|

| Composition | Copper, tin, and lead | Copper and tin, no lead |

| Lead Content | Typically 5-8% | 0% |

| Machinability | Excellent, due to lead | Good, but less than leaded |

| Wear Resistance | Moderate | Higher wear resistance |

| Environmental Impact | Contains toxic lead, harmful | Lead free, eco-friendly |

| Applications | Bearings, bushings, fittings | Food, marine, plumbing |

| Health Concerns | Lead exposure risk | No lead-related risk |

Introduction to Leaded and Unleaded Bronze

Leaded bronze contains a small percentage of lead, typically between 2% and 11%, which enhances its machinability, wear resistance, and self-lubricating properties, making it ideal for bearing and bushing applications. Unleaded bronze eliminates lead for environmental and health reasons, relying on other alloying elements like tin, phosphorus, or silicon to maintain strength and corrosion resistance. Both types are widely used in industrial applications, but leaded bronze offers better performance in high-friction scenarios, while unleaded bronze meets stricter regulatory standards.

Chemical Composition: Leaded vs Unleaded Bronze

Leaded bronze typically contains 6-12% lead, which enhances machinability and reduces friction, making it ideal for bearing and bushing applications. Unleaded bronze replaces lead with elements like tin, phosphorus, or aluminum, improving corrosion resistance and environmental safety. The chemical composition differences directly impact mechanical properties and suitability for specific industrial uses.

Mechanical Properties Comparison

Leaded bronze exhibits superior machinability and higher wear resistance due to the presence of lead, which acts as a solid lubricant, enhancing its mechanical properties under friction. Unleaded bronze offers greater strength and corrosion resistance, making it more suitable for structural applications where durability is critical. Mechanical properties such as tensile strength and hardness are typically higher in unleaded bronze, while leaded bronze excels in reducing friction and improving sliding performance in bearings and bushings.

Corrosion Resistance Differences

Leaded bronze offers enhanced corrosion resistance due to the presence of lead, which improves machinability and reduces friction, helping to form a protective oxide layer that guards against oxidation and wear. Unleaded bronze, lacking lead, may have slightly lower corrosion resistance but provides better environmental compliance and is often preferred in applications requiring food safety or non-toxic materials. The choice between leaded and unleaded bronze impacts longevity and maintenance in marine, hydraulic, and bearing applications where corrosion resistance is critical.

Machinability of Leaded and Unleaded Bronze

Leaded bronze exhibits superior machinability due to the presence of lead, which acts as a lubricant and reduces tool wear, enabling faster cutting speeds and smoother finishes. Unleaded bronze, lacking this additive, tends to be harder and more brittle, resulting in increased tool wear and slower machining processes. Manufacturers often prefer leaded bronze for complex machining tasks requiring precision and efficiency.

Health and Environmental Concerns

Leaded bronze contains added lead, which improves machinability but poses significant health risks due to lead's toxicity, including potential neurological damage and environmental contamination through metal runoff. Unleaded bronze eliminates these risks by using safer alloying elements such as tin and phosphorus, making it a more environmentally friendly and health-conscious choice. Regulatory agencies increasingly restrict lead use, promoting unleaded bronze in applications requiring human contact or ecological sensitivity.

Industrial Applications: When to Use Each Alloy

Leaded bronze offers superior machinability and wear resistance, making it ideal for heavy-duty industrial applications such as bearings, gears, and bushings that require high load capacity and reduced friction. Unleaded bronze, with its enhanced corrosion resistance and non-toxic properties, is preferred in food processing, marine environments, and applications involving potable water systems. Choosing between leaded and unleaded bronze depends on specific operational requirements, balancing machinability and environmental safety.

Regulatory Standards and Compliance

Leaded bronze contains varying amounts of lead, which is regulated under environmental standards such as the EU RoHS Directive and the U.S. EPA regulations that limit lead content to reduce toxicity and environmental impact. Unleaded bronze complies with stricter regulations by eliminating lead content, making it suitable for applications requiring non-toxic materials, including food processing and potable water systems. Compliance with organizations like NSF International ensures unleaded bronze alloys meet safety standards for human contact, driving industry shifts towards lead-free alternatives.

Cost Analysis: Leaded vs Unleaded Bronze

Leaded bronze typically offers lower material costs and improved machinability, resulting in reduced manufacturing expenses compared to unleaded bronze. Unleaded bronze, while generally more expensive due to higher alloy purity and stricter environmental regulations, incurs long-term cost benefits through enhanced corrosion resistance and environmental compliance savings. Cost analysis between leaded and unleaded bronze must balance upfront material prices against potential regulatory fines and product lifespan in industrial applications.

Future Trends in Bronze Alloy Development

Leaded bronze remains valued for its excellent machinability and wear resistance, but future trends emphasize unleaded bronze due to environmental regulations and sustainability goals. Research in bronze alloy development is focusing on optimizing unleaded compositions that retain or surpass the mechanical and thermal properties of leaded variants. Innovations in alloying elements and processing techniques aim to enhance performance in automotive, aerospace, and industrial applications while minimizing ecological impact.

Leaded bronze vs Unleaded bronze Infographic

materialdif.com

materialdif.com