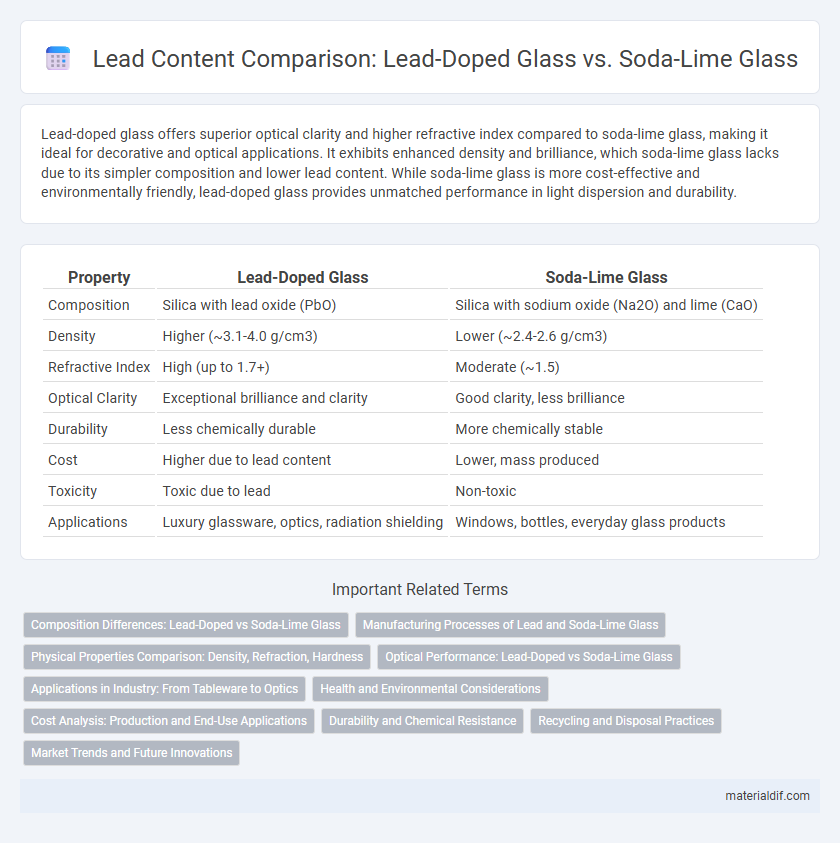

Lead-doped glass offers superior optical clarity and higher refractive index compared to soda-lime glass, making it ideal for decorative and optical applications. It exhibits enhanced density and brilliance, which soda-lime glass lacks due to its simpler composition and lower lead content. While soda-lime glass is more cost-effective and environmentally friendly, lead-doped glass provides unmatched performance in light dispersion and durability.

Table of Comparison

| Property | Lead-Doped Glass | Soda-Lime Glass |

|---|---|---|

| Composition | Silica with lead oxide (PbO) | Silica with sodium oxide (Na2O) and lime (CaO) |

| Density | Higher (~3.1-4.0 g/cm3) | Lower (~2.4-2.6 g/cm3) |

| Refractive Index | High (up to 1.7+) | Moderate (~1.5) |

| Optical Clarity | Exceptional brilliance and clarity | Good clarity, less brilliance |

| Durability | Less chemically durable | More chemically stable |

| Cost | Higher due to lead content | Lower, mass produced |

| Toxicity | Toxic due to lead | Non-toxic |

| Applications | Luxury glassware, optics, radiation shielding | Windows, bottles, everyday glass products |

Composition Differences: Lead-Doped vs Soda-Lime Glass

Lead-doped glass contains a significant amount of lead oxide (PbO), typically ranging from 18% to 40%, which enhances its refractive index and density, providing exceptional brilliance and clarity. In contrast, soda-lime glass primarily consists of silica (SiO2, about 70-75%), soda (Na2O, 12-15%), and lime (CaO, 5-10%), offering greater durability and affordability but lower optical properties. These compositional differences directly influence their applications, with lead-doped glass favored for fine optical lenses and decorative items, while soda-lime glass is commonly used in windows and bottles.

Manufacturing Processes of Lead and Soda-Lime Glass

Lead-doped glass manufacturing involves melting silica, lead oxide, and other additives at higher temperatures, typically around 1400degC, producing a material with increased density and refractive index. Soda-lime glass is manufactured by melting silica, soda ash, and limestone at approximately 1700degC, resulting in a more cost-effective and widely used glass with moderate durability. The incorporation of lead oxide in lead glass requires precise temperature control to ensure uniform dispersion and desired optical properties.

Physical Properties Comparison: Density, Refraction, Hardness

Lead-doped glass exhibits a higher density, typically around 3.1 to 4.0 g/cm3, compared to soda-lime glass, which has a density near 2.5 g/cm3. The refractive index of lead-doped glass ranges from 1.7 to 1.9, significantly exceeding the 1.5 to 1.52 range of soda-lime glass, enhancing its brilliance and clarity. Although lead-doped glass is softer, with a Mohs hardness of approximately 5 to 5.5, soda-lime glass is harder, measuring around 6 to 6.5, increasing its resistance to scratches and wear.

Optical Performance: Lead-Doped vs Soda-Lime Glass

Lead-doped glass exhibits superior optical performance compared to soda-lime glass due to its higher refractive index and enhanced brilliance, which results from the incorporation of lead oxide. This type of glass offers improved clarity, increased light dispersion, and better resistance to UV radiation, making it ideal for high-quality lenses and decorative applications. In contrast, soda-lime glass, while more cost-effective and mechanically durable, has a lower refractive index and less optical clarity, limiting its use in precision optics.

Applications in Industry: From Tableware to Optics

Lead-doped glass offers superior clarity, high refractive index, and enhanced brilliance, making it ideal for luxury tableware and decorative items in the glassware industry. Soda-lime glass, valued for its low cost and durability, dominates in mass production of windows, bottles, and containers. In optics, lead-doped glass is preferred for precision lenses and radiation shielding due to its density and light-bending properties, whereas soda-lime glass serves standard eyewear and display panels.

Health and Environmental Considerations

Lead-doped glass contains toxic lead compounds that pose significant health risks, including lead poisoning and neurotoxicity, especially during manufacturing or disposal processes. Soda-lime glass, composed primarily of silica, soda, and lime, is non-toxic and environmentally safer, with minimal hazardous emissions during production. Recycling lead-doped glass requires specialized handling to prevent environmental contamination, whereas soda-lime glass recycling is more straightforward and widely established.

Cost Analysis: Production and End-Use Applications

Lead-doped glass incurs higher production costs due to the expense of lead oxide and specialized manufacturing processes, while soda-lime glass benefits from low-cost raw materials and established mass production techniques. The increased cost of lead-doped glass is offset in applications requiring enhanced optical properties and radiation shielding, such as in scientific instruments and medical imaging, where performance justifies the premium. Conversely, soda-lime glass dominates cost-sensitive end-use applications like windows, containers, and everyday glassware, offering economic efficiency without advanced functional benefits.

Durability and Chemical Resistance

Lead-doped glass exhibits superior durability and enhanced chemical resistance compared to soda-lime glass, making it more resistant to scratches, impacts, and chemical corrosion. The incorporation of lead oxide in lead-doped glass increases its density and structural robustness, contributing to longer-lasting performance in harsh environments. Soda-lime glass, while cost-effective and widely used, is more susceptible to weathering and chemical degradation due to its lower resistance to alkalis and acids.

Recycling and Disposal Practices

Lead-doped glass requires specialized recycling processes due to the toxic nature of lead, necessitating controlled handling and disposal to prevent environmental contamination. Soda-lime glass, being non-toxic and more abundant, is widely accepted in standard recycling streams, facilitating easier and more cost-effective recycling methods. Proper separation and treatment of lead-doped glass waste are critical to minimize hazardous exposure during disposal and recycling operations.

Market Trends and Future Innovations

Lead-doped glass continues to dominate luxury and optical markets due to its superior refractive index and brilliance, with industry reports forecasting steady growth driven by demand in high-end jewelry and precision optics. Soda-lime glass remains the most widely produced glass type globally, favored in construction and packaging for its cost-efficiency and recyclability, with emerging trends emphasizing eco-friendly manufacturing processes. Future innovations include the development of lead-free alternatives with comparable optical properties to lead-doped glass, and advancements in soda-lime glass formulas enhancing durability and energy efficiency for sustainable architecture.

Lead-doped glass vs Soda-lime glass Infographic

materialdif.com

materialdif.com