Lead sheathing offers superior durability and corrosion resistance compared to PVC sheathing, making it ideal for long-term protection in harsh environments. Unlike PVC, lead sheathing provides excellent shielding against moisture, chemicals, and UV radiation, ensuring cable longevity. This makes lead sheathing a preferred choice for industrial and underground applications where enhanced protection is critical.

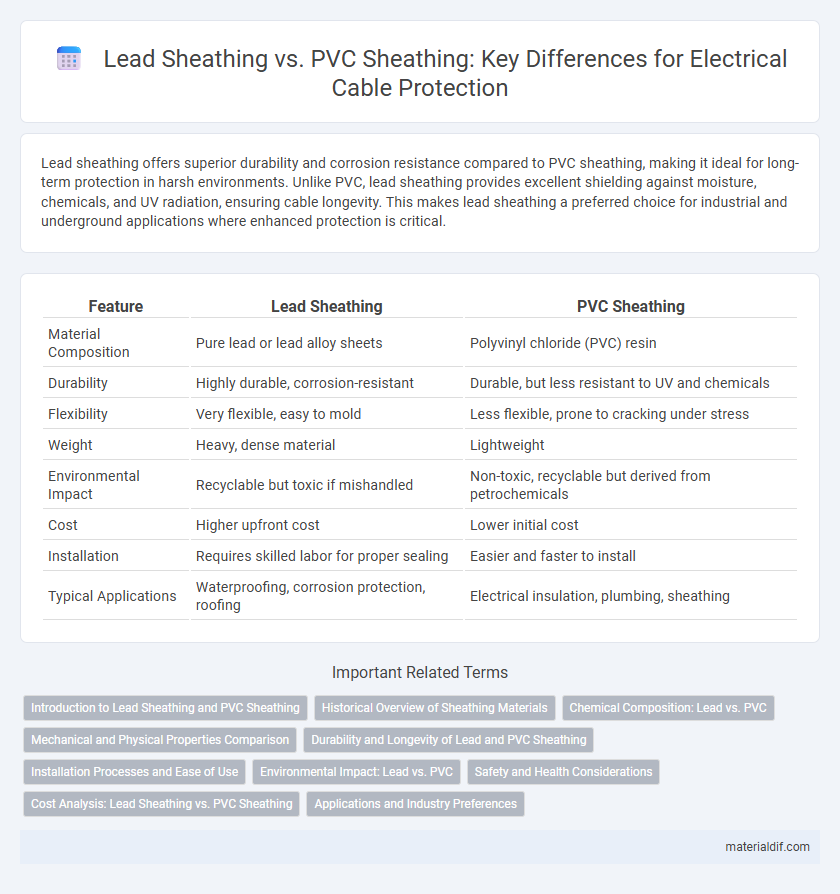

Table of Comparison

| Feature | Lead Sheathing | PVC Sheathing |

|---|---|---|

| Material Composition | Pure lead or lead alloy sheets | Polyvinyl chloride (PVC) resin |

| Durability | Highly durable, corrosion-resistant | Durable, but less resistant to UV and chemicals |

| Flexibility | Very flexible, easy to mold | Less flexible, prone to cracking under stress |

| Weight | Heavy, dense material | Lightweight |

| Environmental Impact | Recyclable but toxic if mishandled | Non-toxic, recyclable but derived from petrochemicals |

| Cost | Higher upfront cost | Lower initial cost |

| Installation | Requires skilled labor for proper sealing | Easier and faster to install |

| Typical Applications | Waterproofing, corrosion protection, roofing | Electrical insulation, plumbing, sheathing |

Introduction to Lead Sheathing and PVC Sheathing

Lead sheathing offers superior durability and corrosion resistance, making it ideal for protecting underground pipes and cables in harsh environments. PVC sheathing provides a lightweight, cost-effective alternative with excellent flexibility and chemical resistance, commonly used in residential and commercial wiring applications. Choosing between lead and PVC sheathing depends on factors such as environmental exposure, mechanical protection needs, and budget constraints.

Historical Overview of Sheathing Materials

Lead sheathing has been used since Roman times due to its durability and corrosion resistance, especially in plumbing and roofing applications. PVC sheathing emerged in the mid-20th century as a lightweight, cost-effective alternative with enhanced chemical resistance and ease of installation. Historical adoption of lead sheathing declined sharply with rising health and environmental concerns, leading to increased use of PVC and other synthetic materials in modern construction.

Chemical Composition: Lead vs. PVC

Lead sheathing consists primarily of elemental lead (Pb), a dense metal known for its exceptional corrosion resistance and malleability, making it ideal for long-term protection in harsh environments. PVC sheathing is composed of polyvinyl chloride, a synthetic polymer made from vinyl chloride monomers, offering flexibility, chemical resistance, and insulation properties through its organic polymer matrix. While lead resists degradation from chemicals and moisture due to its metallic nature, PVC's chemical stability derives from its chlorine content, which enhances fire retardancy and resistance to acids and alkalis.

Mechanical and Physical Properties Comparison

Lead sheathing offers superior malleability and durability compared to PVC sheathing, making it highly resistant to impact and mechanical stress. PVC sheathing provides excellent electrical insulation and chemical resistance but tends to be less flexible and more prone to cracking under mechanical strain. The choice between lead and PVC sheathing depends on specific application requirements, balancing flexibility, mechanical protection, and environmental resilience.

Durability and Longevity of Lead and PVC Sheathing

Lead sheathing offers exceptional durability due to its resistance to corrosion, weathering, and UV radiation, often lasting over 100 years with minimal maintenance. PVC sheathing provides good durability with resistance to moisture and chemicals but typically has a shorter lifespan, averaging 20 to 30 years before degradation occurs. The inherent flexibility and density of lead contribute to its superior longevity compared to PVC, which can become brittle and crack over time under harsh environmental conditions.

Installation Processes and Ease of Use

Lead sheathing offers high malleability, allowing for precise fitting around complex shapes with minimal tools, streamlining installation in roofing and flashing applications. PVC sheathing provides lightweight handling and uniform thickness, enabling quicker, less labor-intensive installation but requiring specialized adhesives and cutting tools. Both materials demand surface preparation, though lead's flexibility reduces alignment challenges compared to rigid PVC sheathing, influencing overall labor time and cost.

Environmental Impact: Lead vs. PVC

Lead sheathing poses significant environmental risks due to its toxicity and potential for soil and water contamination during manufacturing, use, or disposal. PVC sheathing, while less toxic, involves the release of hazardous chemicals like dioxins during production and incineration, contributing to pollution and human health concerns. Selecting eco-friendly alternatives with lower environmental footprints, such as recycled or bio-based materials, can mitigate adverse impacts associated with both lead and PVC sheathing.

Safety and Health Considerations

Lead sheathing offers superior durability and corrosion resistance but poses significant health risks due to lead exposure, which can cause neurological damage and other serious health issues. PVC sheathing, while less durable, eliminates the risk of lead poisoning and is safer for workers and the environment during installation and disposal. Proper handling, protective equipment, and adherence to safety regulations are critical when working with lead sheathing to minimize lead dust and fume inhalation.

Cost Analysis: Lead Sheathing vs. PVC Sheathing

Lead sheathing typically involves higher initial material and installation costs compared to PVC sheathing due to its density and specialized handling requirements. PVC sheathing offers a more cost-effective solution with lower purchasing and labor expenses, making it attractive for budget-conscious projects. Long-term maintenance costs are usually lower for PVC because it resists corrosion and weathering better than lead, which may require periodic inspection and repair.

Applications and Industry Preferences

Lead sheathing is widely preferred in historical building restoration and roofing due to its excellent durability, corrosion resistance, and malleability, making it ideal for complex architectural details. PVC sheathing, favored in modern construction and electrical installations, offers cost-effectiveness, lightweight properties, and chemical resistance suitable for protective cable covering and underground conduits. Industry preferences lean towards lead in heritage conservation and high-end roofing, while PVC dominates in commercial electrical applications and large-scale infrastructure projects.

Lead sheathing vs PVC sheathing Infographic

materialdif.com

materialdif.com