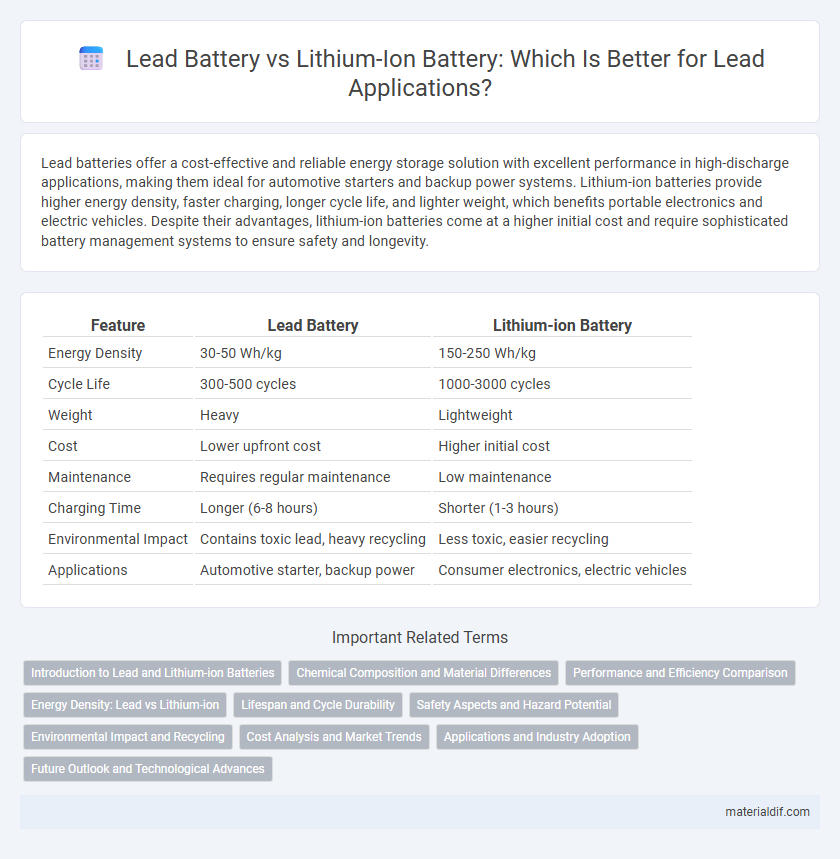

Lead batteries offer a cost-effective and reliable energy storage solution with excellent performance in high-discharge applications, making them ideal for automotive starters and backup power systems. Lithium-ion batteries provide higher energy density, faster charging, longer cycle life, and lighter weight, which benefits portable electronics and electric vehicles. Despite their advantages, lithium-ion batteries come at a higher initial cost and require sophisticated battery management systems to ensure safety and longevity.

Table of Comparison

| Feature | Lead Battery | Lithium-ion Battery |

|---|---|---|

| Energy Density | 30-50 Wh/kg | 150-250 Wh/kg |

| Cycle Life | 300-500 cycles | 1000-3000 cycles |

| Weight | Heavy | Lightweight |

| Cost | Lower upfront cost | Higher initial cost |

| Maintenance | Requires regular maintenance | Low maintenance |

| Charging Time | Longer (6-8 hours) | Shorter (1-3 hours) |

| Environmental Impact | Contains toxic lead, heavy recycling | Less toxic, easier recycling |

| Applications | Automotive starter, backup power | Consumer electronics, electric vehicles |

Introduction to Lead and Lithium-ion Batteries

Lead batteries, also known as lead-acid batteries, utilize lead dioxide and sponge lead as electrodes with sulfuric acid as the electrolyte, offering reliable power storage primarily for automotive and backup applications. Lithium-ion batteries feature lithium-based cathodes and carbon anodes, delivering higher energy density, longer cycle life, and lighter weight, making them ideal for portable electronics and electric vehicles. The fundamental differences in chemistry and performance characteristics define their suitability across diverse energy storage needs.

Chemical Composition and Material Differences

Lead batteries use lead dioxide (PbO2) cathodes and sponge lead anodes immersed in a sulfuric acid electrolyte, resulting in a dense and heavy chemical composition. Lithium-ion batteries contain lithium cobalt oxide (LiCoO2) or lithium iron phosphate (LiFePO4) cathodes paired with graphite anodes, utilizing lithium salts in an organic solvent electrolyte, which provides a lighter and more energy-dense material profile. These fundamental chemical and material distinctions contribute to the lead battery's robustness and cost-efficiency versus the lithium-ion battery's higher energy density and longer cycle life.

Performance and Efficiency Comparison

Lead batteries have lower energy density and shorter cycle life compared to lithium-ion batteries, affecting their performance in high-demand applications. Lithium-ion batteries exhibit higher charge-discharge efficiency, faster charging times, and better energy retention, making them more suitable for portable electronics and electric vehicles. Despite higher upfront costs, lithium-ion's superior power-to-weight ratio and longer lifespan contribute to greater overall efficiency in energy storage solutions.

Energy Density: Lead vs Lithium-ion

Lithium-ion batteries have significantly higher energy density, typically ranging from 150 to 250 Wh/kg, compared to lead-acid batteries, which average around 30 to 50 Wh/kg. This higher energy density allows lithium-ion batteries to store more energy in a smaller and lighter package, enhancing portability and efficiency. Lead-acid batteries remain heavier and bulkier, making them less suitable for applications where weight and space are critical.

Lifespan and Cycle Durability

Lead batteries typically offer a lifespan of around 3 to 5 years with cycle durability ranging between 300 to 500 cycles, making them suitable for low-cost, short-term applications. Lithium-ion batteries provide a significantly longer lifespan of 8 to 15 years and cycle durability exceeding 1,000 to 2,000 cycles, which supports high-performance and long-term energy storage needs. The enhanced cycle durability of lithium-ion batteries results in lower replacement frequency and better overall cost efficiency in extended use scenarios.

Safety Aspects and Hazard Potential

Lead batteries exhibit lower thermal runaway risk compared to lithium-ion batteries, which are prone to overheating and potential fires due to their high energy density. Lead batteries contain non-flammable electrolyte, reducing explosion hazards, while lithium-ion batteries use flammable organic solvents that increase fire and toxic gas emission risks during failure. Proper handling and disposal of lead batteries mitigate acid leakage hazards, whereas lithium-ion batteries require stringent protection circuits to avoid short circuits and hazardous incidents.

Environmental Impact and Recycling

Lead batteries possess a well-established recycling infrastructure with a recovery rate exceeding 95%, significantly reducing environmental pollution from heavy metals. In contrast, lithium-ion batteries, while lighter and higher in energy density, face challenges in recycling efficiency and potential resource depletion due to complex extraction processes. The environmental impact of lead batteries is mitigated by mature recycling practices, whereas lithium-ion technology demands advancements in sustainable recycling to address toxicity and resource sustainability concerns.

Cost Analysis and Market Trends

Lead batteries offer a significantly lower upfront cost compared to lithium-ion batteries, making them attractive for budget-sensitive applications despite their heavier weight and lower energy density. Lithium-ion batteries dominate current market trends due to their longer lifespan, higher efficiency, and rapidly decreasing prices driven by advancements in technology and economies of scale. Market forecasts indicate lithium-ion's growing preference in sectors like electric vehicles and renewable energy storage, while lead batteries maintain steady demand in backup power and industrial uses.

Applications and Industry Adoption

Lead batteries remain widely used in automotive starters and backup power systems due to their cost-effectiveness and reliability, especially in heavy industries like construction and telecommunications. Lithium-ion batteries dominate consumer electronics, electric vehicles, and renewable energy storage sectors because of their higher energy density, longer cycle life, and lighter weight. Industry adoption of lithium-ion continues to accelerate in aerospace and grid storage applications, while lead batteries maintain a strong presence where budget constraints and robust performance in extreme conditions are prioritized.

Future Outlook and Technological Advances

Lead batteries remain crucial for applications demanding high surge currents and reliable recycling processes, while lithium-ion batteries continue to advance with higher energy densities and faster charging capabilities. Emerging technologies in lead-acid batteries, such as enhanced carbon additives and improved grid designs, aim to boost cycle life and efficiency. Lithium-ion innovations focus on solid-state electrolytes and silicon-based anodes, promising safer, longer-lasting, and faster-charging energy storage solutions.

Lead battery vs Lithium-ion battery Infographic

materialdif.com

materialdif.com