Lead sheeting offers superior durability and thickness for heavy-duty applications such as radiation shielding and soundproofing, while lead foil is much thinner and flexible, ideal for detailed wrapping and protection tasks. The choice between lead sheeting and lead foil depends on the specific requirements for strength, flexibility, and ease of installation in your project. Lead sheeting provides enhanced structural integrity, whereas lead foil excels in precision and adaptability for smaller or intricate uses.

Table of Comparison

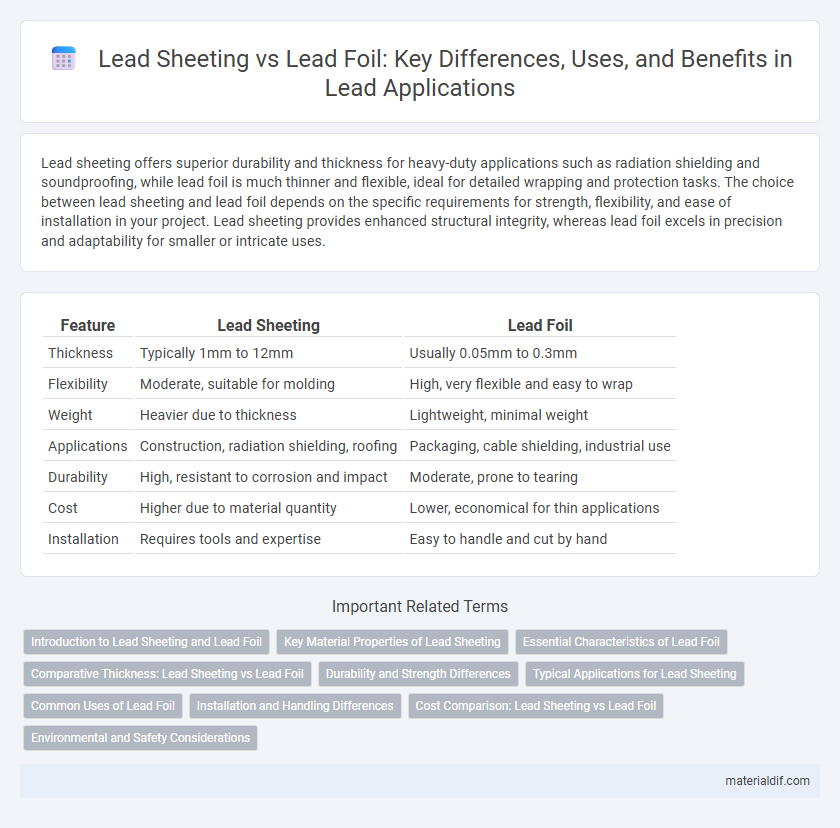

| Feature | Lead Sheeting | Lead Foil |

|---|---|---|

| Thickness | Typically 1mm to 12mm | Usually 0.05mm to 0.3mm |

| Flexibility | Moderate, suitable for molding | High, very flexible and easy to wrap |

| Weight | Heavier due to thickness | Lightweight, minimal weight |

| Applications | Construction, radiation shielding, roofing | Packaging, cable shielding, industrial use |

| Durability | High, resistant to corrosion and impact | Moderate, prone to tearing |

| Cost | Higher due to material quantity | Lower, economical for thin applications |

| Installation | Requires tools and expertise | Easy to handle and cut by hand |

Introduction to Lead Sheeting and Lead Foil

Lead sheeting is a thick, durable material commonly used in construction and radiation shielding due to its high density and malleability, providing effective protection against X-rays and gamma rays. Lead foil, on the other hand, is a much thinner form of lead, often utilized in laboratory settings, packaging, and cable shielding where flexibility and precision are required. Both materials serve specialized functions, with lead sheeting preferred for structural applications and lead foil suited for delicate or intricate uses.

Key Material Properties of Lead Sheeting

Lead sheeting offers superior corrosion resistance and flexibility compared to lead foil, making it ideal for applications requiring long-term durability and weatherproofing. Its thickness typically ranges from 0.7mm to 3.0mm, providing enhanced mechanical strength and ease of shaping without tearing. The high density and malleability of lead sheeting also contribute to effective radiation shielding and soundproofing in construction and industrial uses.

Essential Characteristics of Lead Foil

Lead foil is characterized by its ultra-thin, flexible properties, typically measuring less than 0.2 mm in thickness, allowing for easy molding and wrapping around complex shapes. Unlike thicker lead sheeting, lead foil offers superior conformability and is highly effective in radiation shielding, providing an essential barrier in medical and industrial applications. The material's high density and malleability ensure optimal protection while maintaining lightweight and adaptable coverage.

Comparative Thickness: Lead Sheeting vs Lead Foil

Lead sheeting generally has a significantly greater thickness compared to lead foil, typically ranging from 0.5 mm to several millimeters, while lead foil usually measures between 0.1 mm and 0.5 mm. This difference in thickness directly impacts the flexibility, durability, and shielding effectiveness of each material, with lead sheeting offering superior structural strength and radiation protection. Applications requiring substantial barrier properties often favor lead sheeting, whereas lead foil is preferred for lightweight, flexible uses.

Durability and Strength Differences

Lead sheeting offers superior durability compared to lead foil due to its greater thickness, making it more resistant to wear, punctures, and environmental damage. The increased strength of lead sheeting ensures better long-term protection in industrial and construction applications, whereas lead foil's thinness makes it more prone to tearing under stress. Consequently, lead sheeting is preferred for structural uses requiring enhanced mechanical stability and longevity.

Typical Applications for Lead Sheeting

Lead sheeting is commonly used in radiation shielding for medical and industrial applications, providing effective protection against X-rays and gamma rays. It is also widely applied in construction for soundproofing and corrosion resistance in roofing and flashing. Typical uses include nuclear facilities, hospitals, and laboratories where high-density material is required to block harmful radiation.

Common Uses of Lead Foil

Lead foil is commonly used in radiation shielding for medical and dental X-ray protection due to its malleability and dense atomic structure. It also serves in electronics for battery components and in automotive applications as a protective barrier against corrosion. Unlike lead sheeting, lead foil is preferred for applications requiring thinner, flexible material with precise thickness control.

Installation and Handling Differences

Lead sheeting offers greater rigidity, making it easier to cut and shape for roofing and flashing applications, while lead foil is thinner and more flexible but requires careful handling to avoid tearing. Installation of lead sheeting typically involves mechanical fixing with nails or clips, providing a secure hold, whereas lead foil is often adhered using adhesives or placed beneath other materials for discreet waterproofing. Handling lead foil demands precision due to its delicate nature, contrasting with the sturdy form of lead sheeting that withstands rougher manipulation.

Cost Comparison: Lead Sheeting vs Lead Foil

Lead sheeting generally incurs higher initial costs due to thicker, heavier material usage and more complex installation requirements, making it more expensive upfront compared to lead foil. Lead foil offers cost savings with its thinner profile and ease of handling, reducing material and labor expenses in applications such as roofing, radiation shielding, or insulation. Overall, choosing between lead sheeting and lead foil depends on balancing budget constraints with project-specific durability and performance needs.

Environmental and Safety Considerations

Lead sheeting offers superior durability and thickness compared to lead foil, providing enhanced protection against environmental contaminants and mechanical damage. Due to its solid composition, lead sheeting reduces the risk of lead dust and particle contamination, thereby minimizing health hazards in handling and disposal. Proper use and disposal protocols for both materials are essential to mitigate lead exposure and environmental toxicity, with lead sheeting generally posing fewer safety concerns during application.

Lead sheeting vs Lead foil Infographic

materialdif.com

materialdif.com