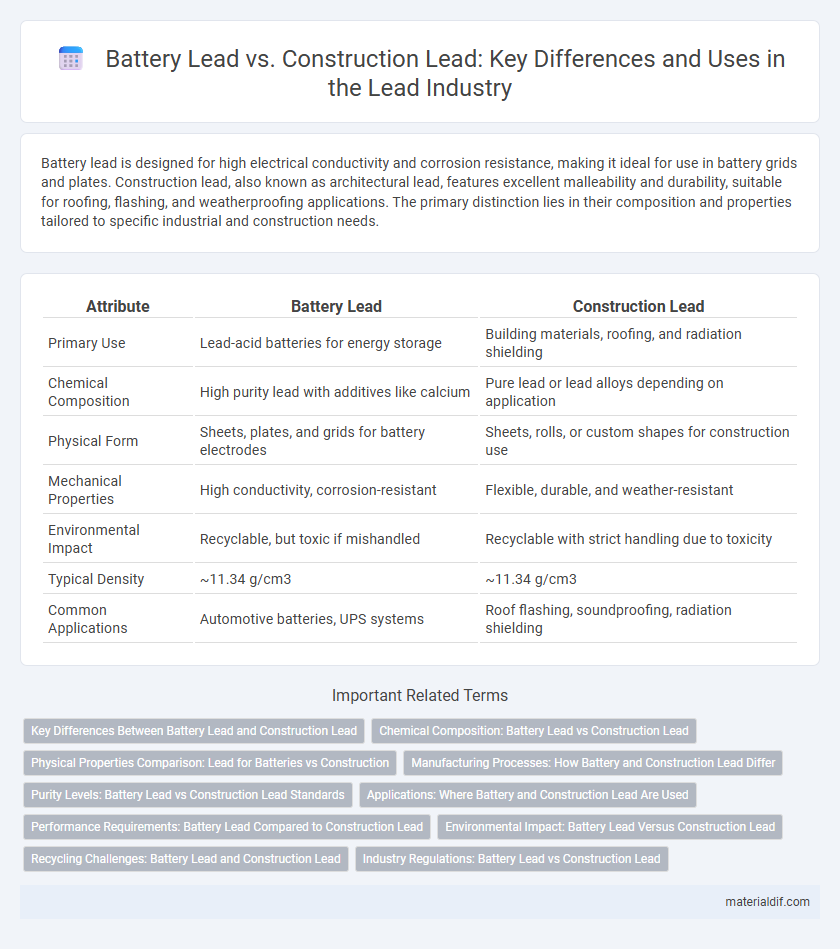

Battery lead is designed for high electrical conductivity and corrosion resistance, making it ideal for use in battery grids and plates. Construction lead, also known as architectural lead, features excellent malleability and durability, suitable for roofing, flashing, and weatherproofing applications. The primary distinction lies in their composition and properties tailored to specific industrial and construction needs.

Table of Comparison

| Attribute | Battery Lead | Construction Lead |

|---|---|---|

| Primary Use | Lead-acid batteries for energy storage | Building materials, roofing, and radiation shielding |

| Chemical Composition | High purity lead with additives like calcium | Pure lead or lead alloys depending on application |

| Physical Form | Sheets, plates, and grids for battery electrodes | Sheets, rolls, or custom shapes for construction use |

| Mechanical Properties | High conductivity, corrosion-resistant | Flexible, durable, and weather-resistant |

| Environmental Impact | Recyclable, but toxic if mishandled | Recyclable with strict handling due to toxicity |

| Typical Density | ~11.34 g/cm3 | ~11.34 g/cm3 |

| Common Applications | Automotive batteries, UPS systems | Roof flashing, soundproofing, radiation shielding |

Key Differences Between Battery Lead and Construction Lead

Battery lead primarily consists of high-purity lead with specific alloying elements like antimony or calcium to enhance electrical conductivity and corrosion resistance, making it ideal for use in lead-acid batteries. Construction lead, in contrast, is formulated for durability and malleability, often incorporating additives to improve strength and weather resistance for applications such as roofing, piping, and radiation shielding. The key differences lie in their composition, mechanical properties, and intended functions, with battery lead optimized for electrochemical performance and construction lead tailored for structural reliability and environmental exposure.

Chemical Composition: Battery Lead vs Construction Lead

Battery lead primarily consists of high-purity lead with added antimony, calcium, or tin to improve corrosion resistance and mechanical strength, essential for electrochemical stability in lead-acid batteries. Construction lead, often used in roofing and piping, contains lower purity but includes alloys designed for enhanced malleability and durability against environmental exposure. These compositional differences reflect the tailored chemical formulations required to meet the specific performance standards of energy storage versus structural applications.

Physical Properties Comparison: Lead for Batteries vs Construction

Battery lead typically exhibits higher purity and enhanced conductivity to optimize energy storage and discharge efficiency, whereas construction lead prioritizes durability and corrosion resistance for structural applications. Battery lead often has a finer grain structure and is more malleable to facilitate electrode manufacturing, while construction lead is denser and harder to withstand environmental stresses. The density of battery lead ranges around 11.34 g/cm3, similar to construction lead, but its mechanical properties are tailored to electrochemical performance rather than load-bearing capacity.

Manufacturing Processes: How Battery and Construction Lead Differ

Battery lead undergoes precise refining and alloying to enhance electrochemical performance, ensuring high purity and corrosion resistance vital for efficient energy storage in batteries. Construction lead, by contrast, is produced with a focus on mechanical strength and durability, often involving casting or extrusion methods suited for building applications like roofing and cladding. These distinct manufacturing processes reflect the specific material properties required, with battery lead optimized for conductivity and longevity while construction lead emphasizes structural integrity.

Purity Levels: Battery Lead vs Construction Lead Standards

Battery lead typically requires a purity level of 99.97% or higher to ensure optimal electrical conductivity and corrosion resistance, essential for reliable battery performance. Construction lead, used in applications such as roofing and plumbing, may have a lower purity standard, often around 99.5%, as mechanical properties and malleability are prioritized over electrical characteristics. High-purity battery lead minimizes impurities like antimony and arsenic, which can degrade battery life, whereas construction lead tolerates higher impurity levels without compromising structural integrity.

Applications: Where Battery and Construction Lead Are Used

Battery lead is primarily used in automotive batteries, renewable energy storage systems, and uninterruptible power supplies due to its excellent electrical conductivity and corrosion resistance. Construction lead is commonly found in roofing materials, piping, radiation shielding, and soundproofing applications because of its durability, malleability, and high density. Understanding the specific properties of battery and construction lead helps optimize their performance in energy storage and building infrastructure.

Performance Requirements: Battery Lead Compared to Construction Lead

Battery lead requires high purity and exceptional corrosion resistance to ensure efficient energy storage and prolonged battery life, whereas construction lead prioritizes mechanical strength and durability for structural applications. Performance requirements for battery lead include superior conductivity and resistance to sulfation, critical for reliable electrochemical reactions. In contrast, construction lead must withstand environmental stressors and physical impact without significant degradation over time.

Environmental Impact: Battery Lead Versus Construction Lead

Battery lead, primarily used in lead-acid batteries, poses significant environmental risks due to its potential for heavy metal contamination and acid leakage during disposal and recycling processes. Construction lead, commonly found in roofing, piping, and radiation shielding, generally exhibits lower leaching toxicity but can still contribute to soil and water pollution if improperly managed. Effective recycling and strict regulatory measures are essential to mitigate the environmental impact of both battery lead and construction lead, ensuring reduced lead exposure and contamination.

Recycling Challenges: Battery Lead and Construction Lead

Battery lead recycling faces significant challenges due to contamination from acid and hazardous materials, requiring specialized treatment to safely recover pure lead. Construction lead, often embedded in painted surfaces and mixed debris, presents difficulties in sorting and extracting reusable lead without spreading toxic dust or residual contamination. Both types demand stringent environmental regulations and advanced technologies to minimize health risks and maximize recovery efficiency.

Industry Regulations: Battery Lead vs Construction Lead

Industry regulations for battery lead mandate strict limits on lead content, recyclability standards, and hazardous waste handling to minimize environmental and health risks associated with lead-acid batteries. Construction lead regulations emphasize corrosion resistance, structural integrity, and safe installation practices to ensure building safety and compliance with local building codes. Both sectors follow guidelines by agencies such as OSHA, EPA, and REACH, but the specificity of chemical exposure limits and recycling protocols differs significantly between battery lead and construction lead applications.

Battery Lead vs Construction Lead Infographic

materialdif.com

materialdif.com