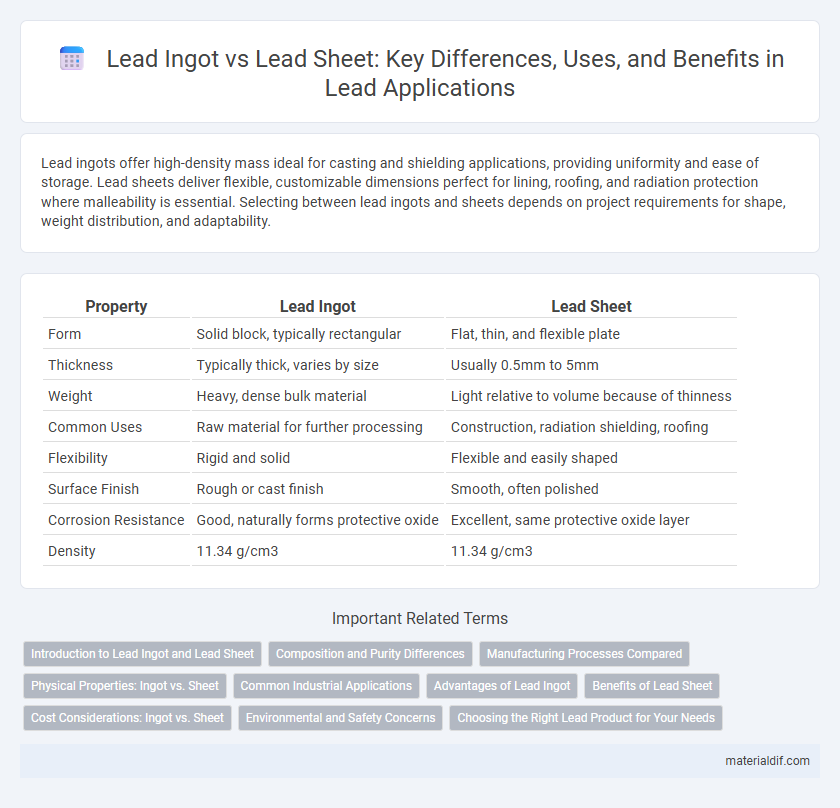

Lead ingots offer high-density mass ideal for casting and shielding applications, providing uniformity and ease of storage. Lead sheets deliver flexible, customizable dimensions perfect for lining, roofing, and radiation protection where malleability is essential. Selecting between lead ingots and sheets depends on project requirements for shape, weight distribution, and adaptability.

Table of Comparison

| Property | Lead Ingot | Lead Sheet |

|---|---|---|

| Form | Solid block, typically rectangular | Flat, thin, and flexible plate |

| Thickness | Typically thick, varies by size | Usually 0.5mm to 5mm |

| Weight | Heavy, dense bulk material | Light relative to volume because of thinness |

| Common Uses | Raw material for further processing | Construction, radiation shielding, roofing |

| Flexibility | Rigid and solid | Flexible and easily shaped |

| Surface Finish | Rough or cast finish | Smooth, often polished |

| Corrosion Resistance | Good, naturally forms protective oxide | Excellent, same protective oxide layer |

| Density | 11.34 g/cm3 | 11.34 g/cm3 |

Introduction to Lead Ingot and Lead Sheet

Lead ingots are dense, solid blocks of lead commonly used as raw material for manufacturing and industrial purposes due to their high purity and ease of storage. Lead sheets are thin, flat pieces of lead metal often utilized in construction, radiation shielding, and soundproofing because of their flexibility and malleability. Both forms offer unique advantages depending on the application, with ingots serving as a primary source for lead processing and sheets providing adaptable solutions for protective and structural uses.

Composition and Purity Differences

Lead ingots typically contain a higher purity level, often exceeding 99.9% lead, making them ideal for industrial applications requiring minimal impurities. Lead sheets may have slightly lower purity due to alloying elements added for enhanced mechanical properties like flexibility and corrosion resistance. The compositional differences influence their suitability, with ingots favored for refining and manufacturing while sheets are preferred for construction and shielding uses.

Manufacturing Processes Compared

Lead ingots are typically produced through a casting process where molten lead is poured into molds and allowed to solidify, offering a dense and uniform structure ideal for further processing or transport. Lead sheets, on the other hand, are manufactured by rolling the lead ingots under controlled temperature conditions to achieve precise thickness and surface finish, ensuring flexibility and ease of use in applications like radiation shielding and roofing. The casting and rolling combination in lead sheet production enables customization of mechanical properties and dimensions, contrasting with the more straightforward ingot casting method.

Physical Properties: Ingot vs. Sheet

Lead ingots possess a dense, compact structure with high mass per volume, enhancing stability and ease of melting for industrial applications, whereas lead sheets offer superior malleability and flexibility, enabling them to be easily cut, shaped, and formed for protective and shielding purposes. The ingot's solid, block form provides higher dimensional stability and uniform density, while lead sheets exhibit variable thickness and can conform to intricate surfaces. Both physical forms retain lead's intrinsic properties such as corrosion resistance and radiation shielding, but the ingot prioritizes bulk handling efficiency and the sheet facilitates versatile application adaptability.

Common Industrial Applications

Lead ingots are primarily used in the recycling and manufacturing industries for producing lead-acid batteries, radiation shielding, and cable sheathing due to their high purity and ease of melting. Lead sheets find extensive applications in construction and industrial fields, such as soundproofing, roofing, and protective barriers against X-rays and gamma radiation because of their flexible, dense, and malleable properties. Both forms of lead are critical in industries requiring corrosion resistance, durability, and effective radiation protection.

Advantages of Lead Ingot

Lead ingots offer higher purity levels compared to lead sheets, making them ideal for industrial applications requiring consistent material quality. Their compact, dense form allows for easier storage and transportation, reducing handling costs and space requirements. Additionally, ingots provide greater versatility in alloying and remelting processes, enabling customized compositions for specific manufacturing needs.

Benefits of Lead Sheet

Lead sheets offer superior flexibility and ease of installation compared to lead ingots, making them ideal for roofing, flashing, and waterproofing applications. Their uniform thickness and malleability ensure precise coverage and better sealing against moisture and environmental elements. Lead sheets also reduce material waste and labor costs due to efficient handling and quicker deployment on site.

Cost Considerations: Ingot vs. Sheet

Lead ingots generally offer a lower cost per pound due to minimal processing requirements compared to lead sheets, which undergo additional manufacturing steps such as rolling and cutting. The sheet form provides enhanced versatility and ease of installation but comes at a premium price reflecting these added fabrication expenses. Budget decisions often weigh the upfront cost savings of ingots against the labor and installation efficiencies enabled by prefabricated lead sheets.

Environmental and Safety Concerns

Lead ingots and lead sheets pose significant environmental and safety concerns due to lead's toxicity and potential for contamination. Lead ingots, being dense and solid, present lower immediate exposure risks but require careful handling during melting or recycling to avoid lead dust and fumes. Lead sheets, often thinner and used in shielding, increase surface area exposure, raising inhalation and contact hazards that necessitate strict protective measures and proper disposal to prevent soil and water pollution.

Choosing the Right Lead Product for Your Needs

Lead ingots offer high purity and ease of melting, making them ideal for applications requiring custom shaping or casting, while lead sheets provide uniform thickness and flat surfaces suitable for roofing, radiation shielding, and soundproofing. Selecting the right lead product depends on factors such as the intended use, thickness requirements, and whether the material needs to be formed or remain in sheet form. Understanding the specific project demands ensures optimal performance and cost-efficiency when choosing between lead ingots and lead sheets.

Lead ingot vs Lead sheet Infographic

materialdif.com

materialdif.com