Rolled lead offers enhanced flexibility and uniform thickness, making it ideal for roofing and flashing applications where precise fitting is crucial. Cast lead, being denser and more rigid, provides superior weight and durability for heavier-duty uses such as ballast and counterweights. Choosing between rolled and cast lead depends on project requirements, balancing workability with strength and longevity.

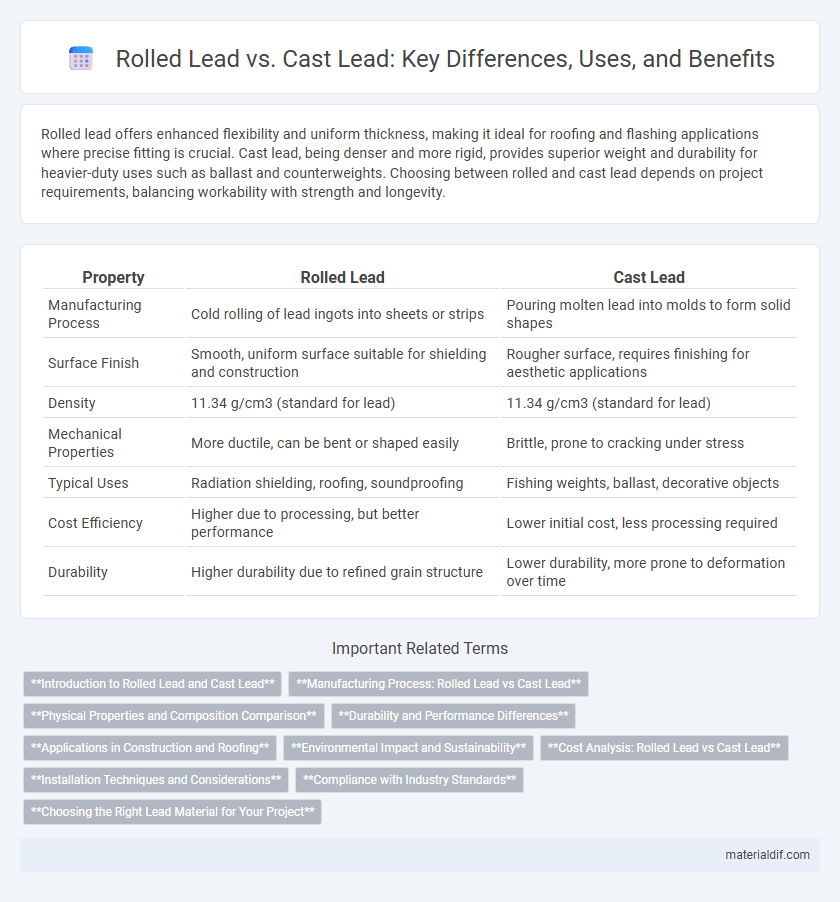

Table of Comparison

| Property | Rolled Lead | Cast Lead |

|---|---|---|

| Manufacturing Process | Cold rolling of lead ingots into sheets or strips | Pouring molten lead into molds to form solid shapes |

| Surface Finish | Smooth, uniform surface suitable for shielding and construction | Rougher surface, requires finishing for aesthetic applications |

| Density | 11.34 g/cm3 (standard for lead) | 11.34 g/cm3 (standard for lead) |

| Mechanical Properties | More ductile, can be bent or shaped easily | Brittle, prone to cracking under stress |

| Typical Uses | Radiation shielding, roofing, soundproofing | Fishing weights, ballast, decorative objects |

| Cost Efficiency | Higher due to processing, but better performance | Lower initial cost, less processing required |

| Durability | Higher durability due to refined grain structure | Lower durability, more prone to deformation over time |

Introduction to Rolled Lead and Cast Lead

Rolled lead is produced by passing molten lead through heavy rollers to create thin sheets, commonly used in roofing, radiation shielding, and soundproofing due to its malleability and uniform thickness. Cast lead is formed by pouring molten lead into molds, resulting in solid blocks or ingots often utilized for ballast, weights, and fishing sinkers because of its dense, compact structure. Understanding the differences between rolled and cast lead is essential for selecting the appropriate form based on application-specific requirements such as flexibility, shape, and density.

Manufacturing Process: Rolled Lead vs Cast Lead

Rolled lead is produced by passing lead through rollers to create thin sheets with uniform thickness, enhancing its malleability and surface finish suitable for applications like roofing and radiation shielding. Cast lead involves melting lead and pouring it into molds, resulting in solid blocks or ingots with varying densities ideal for weights or ballast. The manufacturing process of rolled lead emphasizes mechanical shaping and grain refinement, whereas cast lead focuses on melting and solidification techniques.

Physical Properties and Composition Comparison

Rolled lead exhibits a denser microstructure with fewer inclusions compared to cast lead, resulting in superior tensile strength and flexibility. Its composition is typically purer with minimal alloying elements, enhancing malleability and resistance to cracking. In contrast, cast lead often contains higher levels of impurities and impurities, leading to increased brittleness and lower mechanical performance.

Durability and Performance Differences

Rolled lead exhibits superior durability due to its refined grain structure and enhanced tensile strength, making it more resistant to cracking and deformation under stress compared to cast lead. Cast lead, while offering ease of shaping and cost-effectiveness, often has a coarser microstructure leading to lower mechanical performance and increased susceptibility to wear over time. The inherent structural differences directly impact the longevity and reliability of lead applications in construction and industrial uses.

Applications in Construction and Roofing

Rolled lead, known for its smooth surface and uniform thickness, is widely used in roofing applications such as flashing, gutters, and weatherproofing due to its flexibility and ease of installation. Cast lead, characterized by its dense and coarse texture, is primarily utilized in construction for soundproofing and radiation shielding where durability and weight are critical. Both materials provide excellent corrosion resistance and longevity, making them essential in infrastructure that requires robust protection against environmental factors.

Environmental Impact and Sustainability

Rolled lead typically has a lower environmental impact compared to cast lead due to its production process, which consumes less energy and generates fewer emissions. Rolled lead's recyclability enhances sustainability by enabling repeated reuse without significant degradation, whereas cast lead often involves higher material waste and energy-intensive melting. Choosing rolled lead supports reduced carbon footprint and resource conservation in lead applications.

Cost Analysis: Rolled Lead vs Cast Lead

Rolled lead typically incurs higher production costs due to the additional processing steps required to convert cast lead into thin sheets, while cast lead is generally less expensive as it involves a simpler, direct molding process. The cost difference is influenced by factors such as energy consumption, labor intensity, and material waste, with rolled lead demanding more precise equipment and quality control. Despite the higher initial expense, rolled lead offers improved mechanical properties and uniformity, potentially reducing long-term costs in applications requiring durability and consistent performance.

Installation Techniques and Considerations

Rolled lead offers flexibility and ease of handling, making it ideal for applications requiring precise bending and shaping during installation, while cast lead is more rigid and suited for structural uses where less manipulation is needed. Installation techniques for rolled lead often involve cutting with specialized shears and securing with lead wedges or clips to maintain its form, whereas cast lead requires anchoring with mechanical fasteners or embedding in mortar. Considerations include environmental exposure, as rolled lead provides superior adaptability for waterproofing and flashing, whereas cast lead excels in durability for static, load-bearing applications.

Compliance with Industry Standards

Rolled lead consistently meets stringent industry standards such as ASTM B29 and BS EN 12620, ensuring superior structural integrity and uniform thickness compared to cast lead. Cast lead, while versatile, often exhibits variability in density and may require additional processing to comply with regulatory requirements for purity and mechanical properties. Compliance with these standards is critical for applications in construction, radiation shielding, and plumbing, where material reliability and safety are paramount.

Choosing the Right Lead Material for Your Project

Choosing the right lead material for your project depends on factors such as strength, density, and application requirements. Rolled lead offers greater flexibility and uniform thickness, making it ideal for roofing, flashing, and weatherproofing tasks. Cast lead provides higher density and durability, which suits heavy-duty uses like radiation shielding and ballistic protection.

Rolled lead vs Cast lead Infographic

materialdif.com

materialdif.com