Lead Oxide and Red Lead are both important lead compounds used in industrial applications but differ significantly in their chemical properties and uses. Lead Oxide, often yellow or red, is commonly utilized in battery plates and glass manufacturing due to its ability to improve charge capacity and glass color stability. Red Lead, a bright orange-red powder, serves primarily as a corrosion-resistant primer in paints and coatings, protecting metal surfaces from rust and degradation.

Table of Comparison

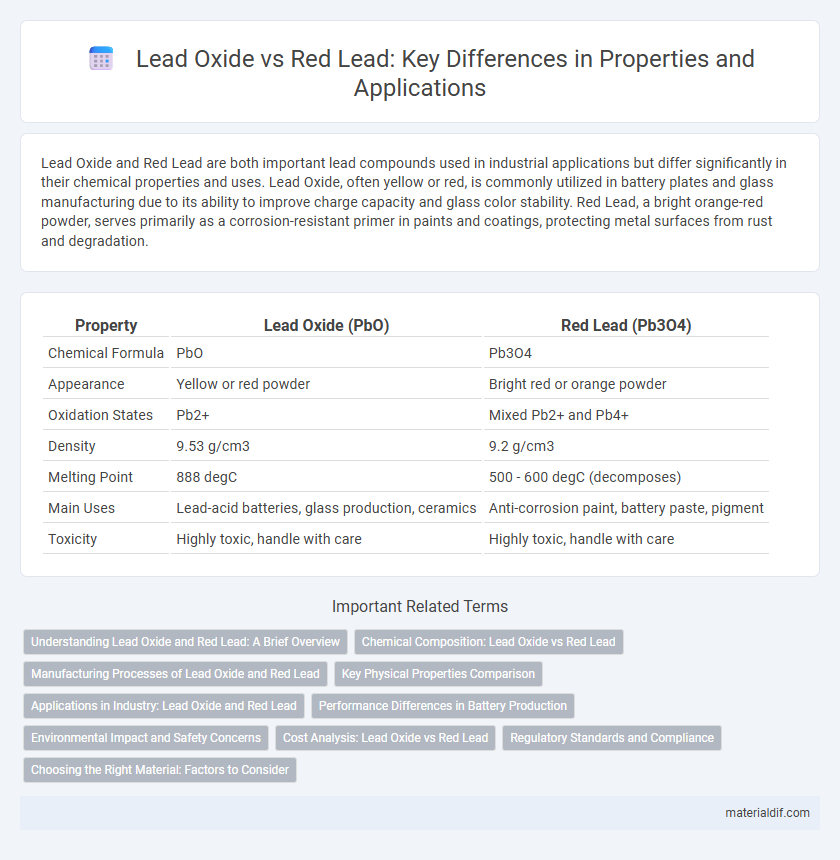

| Property | Lead Oxide (PbO) | Red Lead (Pb3O4) |

|---|---|---|

| Chemical Formula | PbO | Pb3O4 |

| Appearance | Yellow or red powder | Bright red or orange powder |

| Oxidation States | Pb2+ | Mixed Pb2+ and Pb4+ |

| Density | 9.53 g/cm3 | 9.2 g/cm3 |

| Melting Point | 888 degC | 500 - 600 degC (decomposes) |

| Main Uses | Lead-acid batteries, glass production, ceramics | Anti-corrosion paint, battery paste, pigment |

| Toxicity | Highly toxic, handle with care | Highly toxic, handle with care |

Understanding Lead Oxide and Red Lead: A Brief Overview

Lead oxide primarily refers to lead(II) oxide (PbO), a yellow or red powder used in glass, ceramics, and batteries, while red lead (Pb3O4) is a bright red-orange compound valued for its corrosion resistance in paints and rustproof primers. Red lead consists of both Pb(II) oxide and Pb(IV) oxide components, giving it unique oxidative properties compared to the simpler lead(II) oxide. Understanding the chemical differences between lead oxide and red lead is essential for their appropriate industrial application and handling.

Chemical Composition: Lead Oxide vs Red Lead

Lead Oxide primarily consists of PbO, including two main forms: litharge (tetragonal) and massicot (orthorhombic), while Red Lead, or Pb3O4, is a mixed-valence compound containing both Pb2+ and Pb4+ ions. This difference in chemical composition gives Lead Oxide a single oxidation state of +2, whereas Red Lead combines Pb(II) and Pb(IV), resulting in its distinctive bright red color and increased stability. The unique stoichiometry of Red Lead enhances its use as a pigment and corrosion-resistant agent compared to the simpler PbO forms.

Manufacturing Processes of Lead Oxide and Red Lead

Lead oxide is primarily produced through the oxidation of molten lead or lead scrap by controlled heating in a rotary kiln or a ball mill, resulting in a fine, yellow to red powder suitable for battery manufacturing and pigments. Red lead, also known as tetra lead tetroxide, is synthesized by carefully heating lead oxide at high temperatures in air, causing partial oxidation and conversion into a bright red crystalline powder widely used in corrosion-resistant primers and sealing compounds. The manufacturing process of lead oxide emphasizes controlled oxidation to achieve specific particle sizes and chemical purity, while producing red lead requires precise thermal treatment to ensure correct phase transformation and color intensity.

Key Physical Properties Comparison

Lead oxide primarily refers to lead(II) oxide (PbO), which appears as a yellow or red solid with a melting point of 888degC and density around 9.53 g/cm3, while red lead (Pb3O4) is a bright red to orange crystalline powder with a melting point of approximately 500degC and density of about 9.18 g/cm3. Both compounds exhibit significant chemical stability but differ in oxidation states: PbO contains Pb in the +2 state whereas red lead contains mixed Pb(II) and Pb(IV) states, affecting their color and reactivity. These key differences in color, melting point, and density are critical for their varied industrial applications such as pigment manufacturing and battery production.

Applications in Industry: Lead Oxide and Red Lead

Lead oxide and red lead serve distinct roles in industrial applications due to their differing chemical properties; lead oxide is primarily used in the manufacture of lead-acid batteries, pigments, and glass, while red lead is favored for corrosion-resistant coatings, antifouling paints, and as a precursor in the production of other lead compounds. The effectiveness of lead oxide in battery electrodes enhances battery life and efficiency, whereas red lead's excellent durability and anti-corrosive properties make it essential in heavy industry and marine environments. Industries rely on these compounds for their specialized functions, with lead oxide dominating energy storage and red lead providing protective and catalytic benefits.

Performance Differences in Battery Production

Lead oxide, commonly used in battery production, offers high reactivity and improved charge acceptance, enhancing overall battery efficiency and lifespan. Red lead (Pb3O4) exhibits excellent stability and corrosion resistance, making it ideal for battery plates that require robust structural integrity and longer cycle life. The choice between lead oxide and red lead significantly impacts battery performance, with lead oxide favoring faster charge rates and red lead supporting durability under demanding operational conditions.

Environmental Impact and Safety Concerns

Lead oxide and red lead (Pb3O4) differ significantly in environmental impact and safety concerns due to their chemical compositions and applications. Lead oxide, commonly used in batteries and pigments, poses risks of lead poisoning through inhalation or ingestion of dust, while red lead, often employed as a corrosion-resistant primer, contains higher toxic lead content, intensifying environmental contamination and human health hazards. Both substances require strict handling protocols and disposal methods to mitigate soil and water pollution and prevent chronic lead exposure effects.

Cost Analysis: Lead Oxide vs Red Lead

Lead oxide generally costs less than red lead due to its simpler production process and higher availability. Red lead, also known as lead tetraoxide, involves more complex manufacturing steps, resulting in higher market prices and increased handling costs. Evaluating total expenses for industrial applications highlights lead oxide as a more economical choice when cost efficiency is a priority.

Regulatory Standards and Compliance

Lead oxide and red lead are both subject to stringent regulatory standards due to their toxic properties, with agencies like OSHA and EPA enforcing strict handling and exposure limits to protect worker safety and environmental health. Compliance with these standards requires proper labeling, storage, and disposal methods as outlined in OSHA's Hazard Communication Standard and EPA's Toxic Substances Control Act. Red lead, often used as a corrosion-resistant primer, typically demands careful monitoring to meet specific environmental discharge and workplace air quality regulations.

Choosing the Right Material: Factors to Consider

Lead oxide and red lead serve distinct roles in industrial applications, with lead oxide primarily used in lead-acid batteries and glass manufacturing, while red lead excels in anti-corrosion primers and paints. Factors to consider when choosing between these materials include chemical stability, particle size, and intended environmental exposure. Selecting the right compound depends on balancing its protective properties against potential health risks and regulatory compliance.

Lead Oxide vs Red Lead Infographic

materialdif.com

materialdif.com