Leaded glass contains small amounts of lead oxide, enhancing its refractive index and weight, which results in superior clarity and brilliance often favored for decorative and optical applications. Lead-free glass eliminates these toxic elements, making it safer for environmental and health considerations, while advancements in manufacturing allow it to mimic the appearance and strength of traditional leaded glass. Choosing between leaded and lead-free glass depends on balancing optical performance with health and safety priorities.

Table of Comparison

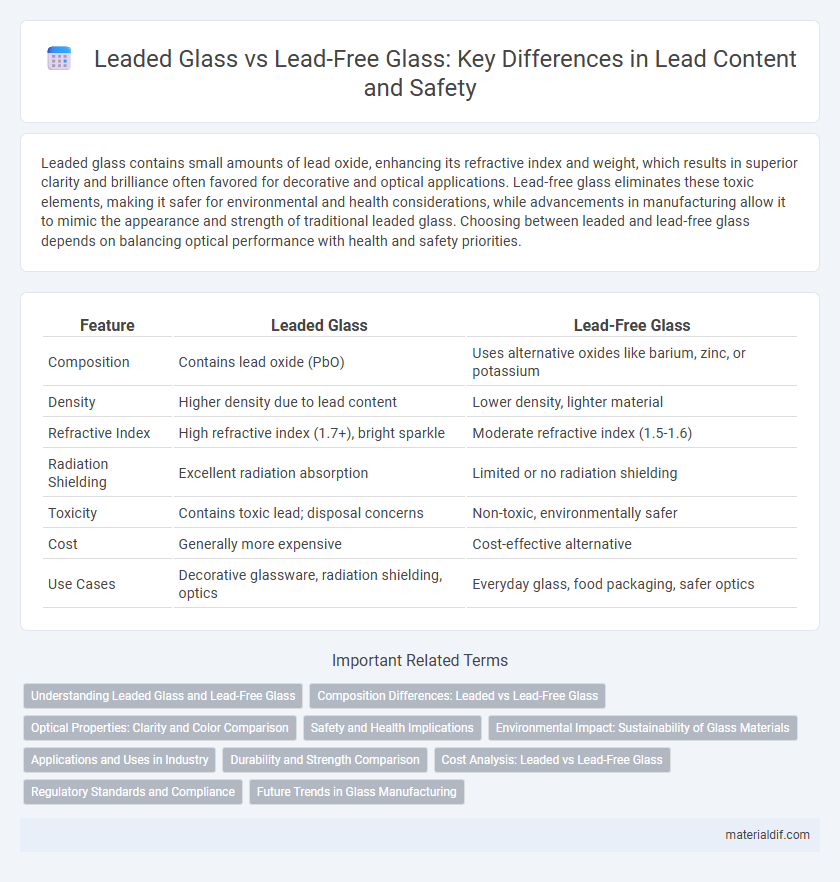

| Feature | Leaded Glass | Lead-Free Glass |

|---|---|---|

| Composition | Contains lead oxide (PbO) | Uses alternative oxides like barium, zinc, or potassium |

| Density | Higher density due to lead content | Lower density, lighter material |

| Refractive Index | High refractive index (1.7+), bright sparkle | Moderate refractive index (1.5-1.6) |

| Radiation Shielding | Excellent radiation absorption | Limited or no radiation shielding |

| Toxicity | Contains toxic lead; disposal concerns | Non-toxic, environmentally safer |

| Cost | Generally more expensive | Cost-effective alternative |

| Use Cases | Decorative glassware, radiation shielding, optics | Everyday glass, food packaging, safer optics |

Understanding Leaded Glass and Lead-Free Glass

Leaded glass contains lead oxide, enhancing its refractive index, brilliance, and weight, making it popular in decorative and optical applications. Lead-free glass substitutes lead with safer alternatives like barium, zinc, or potassium oxides, reducing health and environmental risks without compromising clarity and durability. Understanding the differences helps industries choose glass tailored for safety regulations, performance requirements, and aesthetic purposes.

Composition Differences: Leaded vs Lead-Free Glass

Leaded glass contains lead oxide, typically ranging from 18% to 40%, which enhances its refractive index and brilliance, making it ideal for decorative and optical applications. Lead-free glass substitutes lead oxide with alternative compounds such as barium oxide, zinc oxide, or potassium oxide to maintain clarity and durability while eliminating health risks associated with lead exposure. These composition differences critically influence the glass's density, refractive properties, and environmental impact.

Optical Properties: Clarity and Color Comparison

Leaded glass offers superior clarity and brilliance due to its high refractive index, enhancing light dispersion and producing a vibrant sparkle, whereas lead-free glass typically exhibits less optical brilliance and slightly muted color vibrancy. The color rendition in leaded glass is richer and more intense, benefiting from lead oxide's ability to filter blue light and reduce chromatic aberrations. In contrast, lead-free glass often has a neutral color profile but may lack the depth and warmth characteristic of leaded glass compositions.

Safety and Health Implications

Leaded glass contains lead oxide, which enhances its clarity and refractive properties but poses significant health risks due to lead toxicity, especially during manufacturing or breakage. Lead-free glass eliminates these hazards by using alternative materials like barium or zinc oxides, reducing lead exposure and environmental contamination. Regulatory bodies increasingly favor lead-free glass in consumer products to comply with safety standards and protect public health.

Environmental Impact: Sustainability of Glass Materials

Leaded glass contains toxic lead oxide, posing significant environmental hazards during manufacturing, disposal, and potential leaching into ecosystems. Lead-free glass alternatives use safer compounds like barium or zinc oxides, significantly reducing heavy metal contamination and enhancing recyclability. Choosing lead-free glass supports sustainable production practices by minimizing hazardous waste and promoting safer lifecycle management.

Applications and Uses in Industry

Leaded glass, known for its high refractive index and density, is widely used in applications requiring radiation shielding such as medical imaging and nuclear facilities, as well as in decorative items like chandeliers and optical lenses. Lead-free glass offers an eco-friendly alternative, finding extensive use in food and beverage packaging, pharmaceuticals, and electronic displays due to its lower toxicity and compliance with environmental regulations. Industrial adoption of lead-free glass is increasing in sectors prioritizing sustainability and health safety without compromising clarity and durability.

Durability and Strength Comparison

Leaded glass exhibits superior durability and strength due to the incorporation of lead oxide, which enhances its density and resistance to impact. In contrast, lead-free glass relies on alternative materials like barium or zinc oxides to achieve comparable strength but often falls short in long-term resilience under high stress conditions. The molecular structure of leaded glass provides better resistance to thermal shock, making it more durable for applications requiring both strength and longevity.

Cost Analysis: Leaded vs Lead-Free Glass

Leaded glass typically incurs higher production costs due to the inclusion of lead oxide, which enhances weight and refractive properties but requires specialized handling and disposal. Lead-free glass offers a cost-effective alternative with lower raw material expenses and easier manufacturing processes, reducing environmental compliance costs. When analyzing cost factors, lead-free glass presents savings in both production and long-term regulatory adherence, making it a financially attractive option for many applications.

Regulatory Standards and Compliance

Leaded glass is subject to stringent regulatory standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) due to its high lead content, which poses health and environmental risks. Lead-free glass complies with these regulations by eliminating lead, ensuring safer manufacturing processes and products that meet global safety certifications. Compliance with regulatory standards drives industries to adopt lead-free alternatives to avoid legal penalties and promote sustainability.

Future Trends in Glass Manufacturing

Future trends in glass manufacturing emphasize the shift from traditional leaded glass to innovative lead-free alternatives driven by health and environmental regulations. Advances in material science are enabling the production of high-performance lead-free glass with comparable durability, clarity, and radiation shielding properties. Emerging technologies such as bio-based additives and recyclable glass composites are set to further reduce environmental impact while maintaining functional integrity in architectural and automotive applications.

Leaded glass vs Lead-free glass Infographic

materialdif.com

materialdif.com