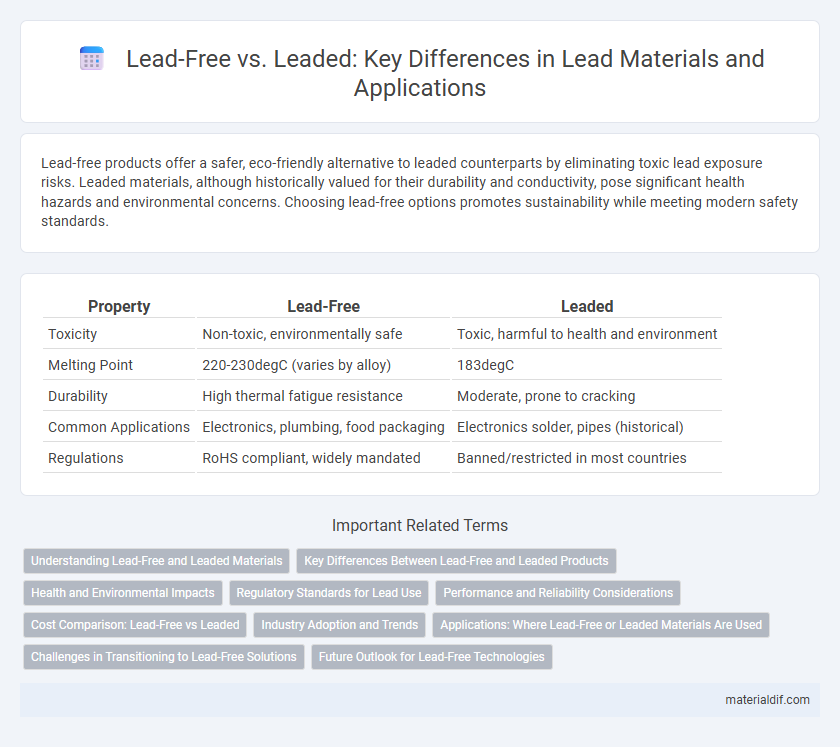

Lead-free products offer a safer, eco-friendly alternative to leaded counterparts by eliminating toxic lead exposure risks. Leaded materials, although historically valued for their durability and conductivity, pose significant health hazards and environmental concerns. Choosing lead-free options promotes sustainability while meeting modern safety standards.

Table of Comparison

| Property | Lead-Free | Leaded |

|---|---|---|

| Toxicity | Non-toxic, environmentally safe | Toxic, harmful to health and environment |

| Melting Point | 220-230degC (varies by alloy) | 183degC |

| Durability | High thermal fatigue resistance | Moderate, prone to cracking |

| Common Applications | Electronics, plumbing, food packaging | Electronics solder, pipes (historical) |

| Regulations | RoHS compliant, widely mandated | Banned/restricted in most countries |

Understanding Lead-Free and Leaded Materials

Lead-free materials, often used in electronics and solders, eliminate toxic lead content to meet environmental regulations such as RoHS, promoting safer manufacturing practices and reducing health risks. Leaded materials contain lead, offering superior mechanical strength, thermal stability, and ease of soldering, which are critical in high-reliability applications like aerospace and military electronics. Understanding the trade-offs between lead-free and leaded materials involves evaluating factors like electrical performance, cost, environmental impact, and compliance with international safety standards.

Key Differences Between Lead-Free and Leaded Products

Lead-free products eliminate the use of toxic lead, significantly reducing health and environmental risks, whereas leaded products contain lead that poses serious hazards. Lead-free alternatives often comply with international regulations like RoHS, ensuring safer electronic manufacturing and disposal. Leaded materials typically offer superior conductivity and durability but are being phased out due to stricter safety standards.

Health and Environmental Impacts

Lead-free materials significantly reduce health risks associated with lead poisoning, such as neurological damage and developmental delays in children. Environmental impacts of leaded products include soil and water contamination, which harm ecosystems and bioaccumulate in wildlife. Transitioning to lead-free alternatives supports public health initiatives and promotes safer environmental conditions globally.

Regulatory Standards for Lead Use

Regulatory standards for lead use vary significantly between lead-free and leaded materials, with lead-free products required to meet stringent limits such as the RoHS Directive, which restricts lead content to a maximum of 0.1%. Leaded materials, while still permitted in certain industrial applications, face increasing restrictions due to toxicological concerns and environmental legislation from agencies like the EPA and REACH. Compliance with these regulations ensures reduced environmental contamination and promotes safer handling and disposal practices in manufacturing and consumer products.

Performance and Reliability Considerations

Lead-free solder alloys, commonly composed of tin, silver, and copper, generally exhibit higher melting points and increased brittleness compared to traditional leaded solders, impacting thermal cycling performance and mechanical reliability in electronic assemblies. Leaded solders, typically tin-lead alloys, provide superior wetting properties and lower melting temperatures, resulting in enhanced joint integrity and reduced risk of thermal stress during manufacturing processes. Reliability assessments often favor leaded solder in high-vibration or high-temperature applications due to its proven ability to withstand mechanical fatigue and maintain electrical conductivity over extended service life.

Cost Comparison: Lead-Free vs Leaded

Lead-free materials generally incur higher upfront costs due to the expense of alternative metals like tin and silver, which are more costly than traditional lead alloys. Leaded products benefit from lower raw material prices and simpler manufacturing processes, resulting in reduced production costs and overall affordability. However, long-term expenses for leaded materials may increase due to regulatory compliance and environmental mitigation requirements.

Industry Adoption and Trends

Industry adoption of lead-free materials has surged due to stringent regulations like RoHS, driving electronics manufacturers to eliminate lead for environmental compliance and enhanced safety. Despite leaded components offering superior reliability in high-temperature and aerospace applications, market trends show a steady decline in their usage as innovations in lead-free solder alloys improve performance. The shift toward lead-free solutions is further propelled by consumer demand for sustainable products and increased investment in green manufacturing technologies.

Applications: Where Lead-Free or Leaded Materials Are Used

Lead-free materials dominate electronics manufacturing due to environmental regulations, especially in consumer devices like smartphones, laptops, and household appliances. Leaded materials remain preferred in aerospace, military, and medical applications where performance reliability under extreme conditions is critical. Automotive industries increasingly adopt lead-free solder to comply with RoHS standards, while some high-reliability sectors continue using leaded solutions for superior fatigue resistance.

Challenges in Transitioning to Lead-Free Solutions

Transitioning from leaded to lead-free solutions presents challenges such as higher melting points of lead-free solders, which can cause thermal stress on components and circuit boards. Compatibility issues arise due to differing mechanical and electrical properties of lead-free alloys, potentially affecting reliability and performance. Stringent regulations and industry standards demand rigorous testing and certification, increasing time and costs in manufacturing processes.

Future Outlook for Lead-Free Technologies

The future outlook for lead-free technologies highlights increasing adoption driven by stringent environmental regulations and growing consumer demand for sustainable products. Innovations in alloy formulations and advanced soldering techniques are enhancing the reliability and performance of lead-free electronic components. Emerging industries, such as electric vehicles and renewable energy, further accelerate the transition toward lead-free solutions, emphasizing long-term ecological and economic benefits.

Lead-Free vs Leaded Infographic

materialdif.com

materialdif.com