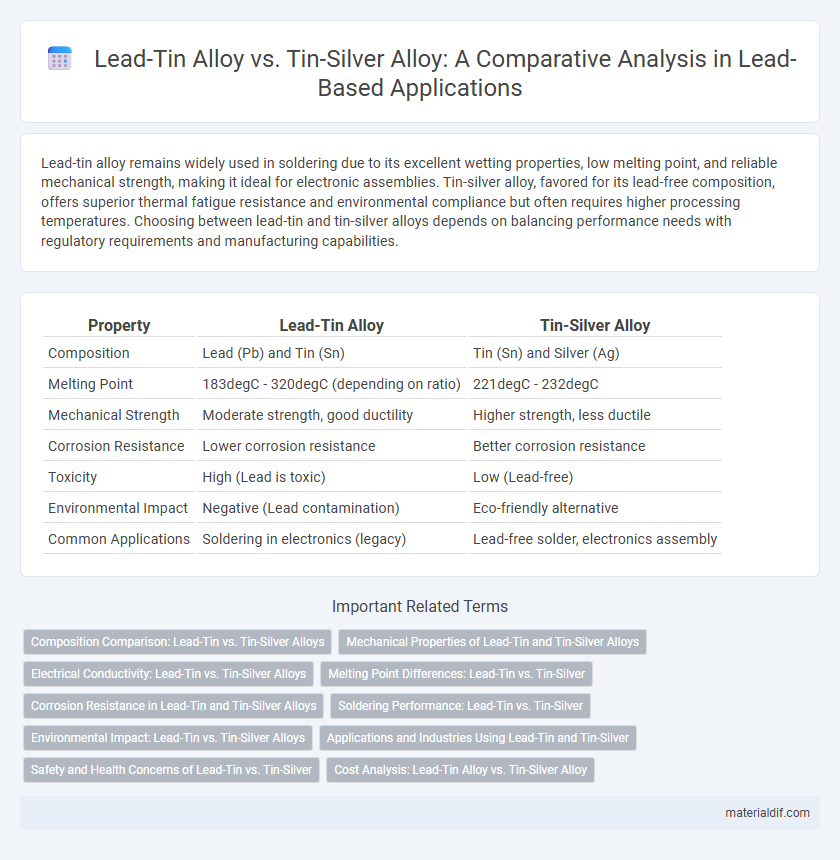

Lead-tin alloy remains widely used in soldering due to its excellent wetting properties, low melting point, and reliable mechanical strength, making it ideal for electronic assemblies. Tin-silver alloy, favored for its lead-free composition, offers superior thermal fatigue resistance and environmental compliance but often requires higher processing temperatures. Choosing between lead-tin and tin-silver alloys depends on balancing performance needs with regulatory requirements and manufacturing capabilities.

Table of Comparison

| Property | Lead-Tin Alloy | Tin-Silver Alloy |

|---|---|---|

| Composition | Lead (Pb) and Tin (Sn) | Tin (Sn) and Silver (Ag) |

| Melting Point | 183degC - 320degC (depending on ratio) | 221degC - 232degC |

| Mechanical Strength | Moderate strength, good ductility | Higher strength, less ductile |

| Corrosion Resistance | Lower corrosion resistance | Better corrosion resistance |

| Toxicity | High (Lead is toxic) | Low (Lead-free) |

| Environmental Impact | Negative (Lead contamination) | Eco-friendly alternative |

| Common Applications | Soldering in electronics (legacy) | Lead-free solder, electronics assembly |

Composition Comparison: Lead-Tin vs. Tin-Silver Alloys

Lead-tin alloys primarily consist of approximately 60-70% tin and 30-40% lead, offering excellent solderability and mechanical strength for electronics. Tin-silver alloys typically contain about 96-98% tin and 2-4% silver, providing superior thermal and electrical conductivity along with enhanced resistance to oxidation. The choice between these alloys depends on environmental regulations, with lead-tin favored for cost-effectiveness and tin-silver preferred for lead-free applications and improved joint reliability.

Mechanical Properties of Lead-Tin and Tin-Silver Alloys

Lead-tin alloys exhibit excellent machinability and superior vibration damping properties, making them ideal for applications requiring mechanical stability and wear resistance. Tin-silver alloys demonstrate higher tensile strength and improved fatigue resistance, with enhanced thermal stability suitable for demanding electronic soldering processes. Both alloys offer distinct mechanical advantages, with lead-tin favoring softness and ductility, while tin-silver prioritizes strength and durability.

Electrical Conductivity: Lead-Tin vs. Tin-Silver Alloys

Lead-tin alloys typically exhibit lower electrical conductivity compared to tin-silver alloys due to the higher atomic mass and electron scattering caused by lead atoms. Tin-silver alloys offer improved conductivity, making them preferable for electronic soldering applications where efficient electron flow is critical. The enhanced electrical performance of tin-silver alloys supports better signal integrity and reduced resistance in electrical connections.

Melting Point Differences: Lead-Tin vs. Tin-Silver

Lead-tin alloys typically melt between 183degC and 320degC depending on the composition, with the eutectic lead-tin solder melting at 183degC, while tin-silver alloys generally exhibit higher melting points, typically ranging from 221degC to 250degC. The higher melting point of tin-silver alloys, such as the common 96.5% tin and 3.5% silver composition melting around 221degC, makes them more suitable for high-temperature applications and lead-free soldering processes. Understanding these melting point differences is crucial for selecting the appropriate solder material for electronics manufacturing and environmental compliance.

Corrosion Resistance in Lead-Tin and Tin-Silver Alloys

Lead-tin alloys exhibit moderate corrosion resistance in solder applications, primarily due to the protective oxide layer formed on the lead surface which inhibits further degradation. Tin-silver alloys offer enhanced corrosion resistance compared to lead-tin alloys, as silver significantly improves the solder's mechanical strength and reduces susceptibility to whisker growth and tarnishing. The superior corrosion resistance of tin-silver alloys makes them preferable in electronics where long-term reliability and environmental compliance are critical.

Soldering Performance: Lead-Tin vs. Tin-Silver

Lead-tin alloys exhibit superior wetting properties and lower melting points, enabling faster and more reliable solder joints in electronic assemblies. Tin-silver alloys, while lead-free and environmentally friendly, require higher reflow temperatures and tend to have slower wetting speeds, which can affect solder joint quality. The choice between lead-tin and tin-silver alloys impacts soldering performance, thermal fatigue resistance, and joint strength in surface-mount technology applications.

Environmental Impact: Lead-Tin vs. Tin-Silver Alloys

Lead-tin alloys pose significant environmental concerns due to lead's toxicity and persistence in ecosystems, leading to soil and water contamination. Tin-silver alloys offer a more eco-friendly alternative as they lack toxic heavy metals and exhibit better recyclability with lower environmental hazards. Regulatory restrictions on lead use in electronics and plumbing favor tin-silver alloys for sustainable manufacturing and compliance with environmental standards.

Applications and Industries Using Lead-Tin and Tin-Silver

Lead-tin alloys are widely used in plumbing, soldering, and battery manufacturing due to their excellent thermal and electrical conductivity combined with corrosion resistance. Tin-silver alloys find extensive application in electronics, particularly in circuit board soldering and high-reliability aerospace components, owing to their superior mechanical strength and lead-free compliance. Both alloys serve critical roles in automotive, electronics, and renewable energy industries, with tin-silver favored in environmentally regulated markets.

Safety and Health Concerns of Lead-Tin vs. Tin-Silver

Lead-tin alloys pose significant health risks due to lead's toxicity, causing neurological damage and requiring stringent exposure controls in manufacturing. Tin-silver alloys offer safer alternatives with minimal toxic effects, reducing occupational hazards and environmental contamination. Regulatory standards increasingly favor tin-silver alloys to mitigate lead-related safety concerns in soldering applications.

Cost Analysis: Lead-Tin Alloy vs. Tin-Silver Alloy

Lead-tin alloys offer a significantly lower material cost compared to tin-silver alloys, primarily due to the abundance and lower market price of lead and tin versus the premium cost of silver. The processing expenses of lead-tin alloys are also reduced because of their lower melting points, which decrease energy consumption during manufacturing. However, tin-silver alloys provide enhanced mechanical properties and corrosion resistance, potentially offsetting initial costs with longer-term durability and lower maintenance expenses.

Lead-tin alloy vs Tin-silver alloy Infographic

materialdif.com

materialdif.com